Abstract—This article presents an overview of Russian and Western works on the application of intensive pulse electron beams for surface treatment of metals, alloys, metal ceramics and ceramic materials. Application advantages of electron pulse beams are highlighted in comparison with laser beams, plasma flows, ion beams. Promising trends of electron beam treatment are analyzed: (1) surface smoothing, elimination of surface microcracks with simultaneous modification of structural phase state of surface layer in order to develop high performance technologies of finishing treatment of critical metal items of complicated shape made of Ti–6Al–4V alloy and titanium, steel of various grades, WC–10% Co solid alloy, aluminum; (2) elimination of micro-burrs formed upon fabrication of precision compression molds (SKD11 steel) and biomedical items (Ti–6Al–4V alloy); (3) finishing surface treatment of compression molds and dies; (4) improvement of functional properties of metallic biomaterials (stainless steel, titanium and its alloys, alloys based on titanium nickelide with shape memory effect, magnesium alloys; (5) treatment of medical items and implants; (6) formation of surface alloys for powerful electrodynamic systems; (7) improvement of specifications of blades of aircraft engines and compressor blades; (8) formation of thermal barrier coatings applied onto surfaces of combustion chambers. Upon correct selection of process variables, such as boosting voltage, electron beam energy density, as well as number and duration of pulses, it is demonstrated that thorough control and/or manipulation of characteristics of structural phase state and surface properties are possible. In order to improve material properties and to increase operation lifetime of items, the important factor is the structure modification aiming at the formation of submicro- or nanoscale grain (or subgrain structure).

Similar content being viewed by others

REFERENCES

Ozur, G.E. and Proskurovskii, D.I., Istochniki nizkoenergeticheskikh sil’notochnykh elektronnykh puchkov s plazmennym anodom (Source of Low-Energy High-Current Electron Beams with Plasma Anode), Koval’, N.N., Ed., Novosibirsk: Nauka, 2018. doi https://doi.org/10.15372/Sources2018OGE

Evolutsiya struktury poverkhnostnogo sloya stali, podvergnutoi elektronno-ionno-plazmennym metodam obrabotki (Evolution of Surface Layer Structure of Steel Subjected to ElectronIonPlasma Treatment), Koval’, N.N. and Ivanov, Yu.F., Eds., Tomsk: Izd-vo Nauchn.-Tekh. Literatury, 2016.

Ivanov, Yu.F., Elektronno-ionno-plazmennaya modifikatsiya poverkhnosti tsvetnykh metallov i splavov (Electron-Ion-Plasma Modification of Surface of Non- Ferrous Metals and Alloys), Tomsk: Izd-vo Nauchn.-Tekh. Literatury, 2016.

Gromov, V.E., Ivanov, Yu.F., Vorobiev, S.V., and Konovalov, S.V., Fatigue of Steels Modified by High Intensity Electron Beams, Cambridge: Int. Science Publ, 2015.

Uno, Y., Okada, A., Uemura, K., and Raharjo, P., Method for surface treating a die by electron beam irradiation and a die treated thereby, US Patent 7049539, 2006.

Murray, J.W., Kinnell, P.K., Cannon, A.H., Bailey, B., and Clare, A.T., Surface finishing of intricate metal mould structures by large-area electron beam irradiation, Precis. Eng., 2013, vol. 37, no. 2, pp. 443–450. https://doi.org/10.1016/j.precisioneng.2012.11.007

Goriainov, V., Cook, R.B., Murray, J.W., Walker, J.C., Dunlop, D.G., Clare, A.T., and Oreffo, R.O.C., Human skeletal stem cell response to multiscale topography induced by large area electron beam irradiation surface treatment, Front. Bioeng. Biotechnol., 2018, vol. 6, p. 91. https://doi.org/10.3389/fbioe.2018.00091

Manufacturing Techniques for Materials. Engineering and Engineered, Srivatsan, T.S., Sudarshan, T.S., and Manigandan, K., Eds., Boca Raton, Fla.: CRC Press, 2018.

Okada, A., Uno, Y., Yabushita, N., Uemura, K., and Raharjo, P., High efficient surface finishing of bio-titanium alloy by large-area electron beam irradiation, J. Mater. Process. Technol., 2004, vol. 149, nos. 1–3, pp. 506–511. https://doi.org/10.1016/j.jmatprotec.2004.02.017

Tokunaga, J., Kojima, T., Kinuta, S., Wakabayashi, K., Nakamura, T., Yatani, H., and Sohmura, T., Large-area electron beam irradiation for surface polishing of cast titanium, Dental Mater. J., 2009, vol. 28, no. 5, pp. 571–577. https://doi.org/10.4012/dmj.28.571

Uno, Y., Okada, A., Uemura, K., Raharjo, P., Sano, S., Yu, Z., and Mishima, S., A new polishing method of metal mold with large-area electron beam irradiation, J. Mater. Process. Technol., 2007, vols. 187–188, pp. 77–80. https://doi.org/10.1016/j.jmatprotec.2006.11.080

Okada, A., Okamoto, Y., Uno, Y., and Uemura, K., Improvement of surface characteristics for long life of metal molds by large-area EB irradiation, J. Mater. Process. Technol., 2014, vol. 214, no. 8, pp. 1740–1748. https://doi.org/10.1016/j.jmatprotec.2014.02.028

Okada, A., Kitada, R., Okamoto, Y., and Uno, Y., Surface modification of cemented carbide by EB polishing, CIRP Ann. Manuf. Technol., 2011, vol. 60, no. 1, pp. 575–578. https://doi.org/10.1016/j.cirp.2011.03.107

Shinonaga, T., Okada, A., Liu, H., and Kimura, M., Magnetic fixture for enhancement of smoothing effect by electron beam melting, J. Mater. Process. Technol., 2018, vol. 254, pp. 229–237. https://doi.org/10.1016/j.jmatprotec.2017.11.024

Okada, A., Yonehara, H., and Okamoto, Y., Fundamental study on micro-deburring by large-area EB irradiation, Procedia CIRP, 2013, vol. 5, pp. 19–24. https://doi.org/10.1016/j.procir.2013.01.004

Zhang, K., Zou, J., Grosdidier, T., Dong, C., and Yang, D., Improved pitting corrosion resistance of AISI 316L stainless steel treated by high current pulsed electron beam, Surf. Coat. Technol., 2006, vol. 201, nos. 3–4, pp. 1393–1400. https://doi.org/10.1016/j.surfcoat.2006.02.008

Rotshtein, V.P., Gyuntsel’, R., Markov A.B., Proskurovskii D.I., Fam M.T, Rikhter E., and Shulov, V.A., Surface modification of a titanium alloy with low-energy high-current electron beam at elevated initial temperatures, Fiz. Khim. Obrab. Mater., 2006, vol. 1, pp. 62–72.

Zhang, X.D., Hao, S.Z., Li, X.N., Dong, C., and Grosdidier, T., Surface modification of pure titanium by pulsed electron beam, Appl. Surf. Sci., 2011, vol. 257, no. 13, pp. 5899–5902. https://doi.org/10.1016/j.apsusc.2011.01.136

Zhang, K.M., Yang, D.Z., Zou, J.X., Grosdidier, T., and Dong, C., Improved in vitro corrosion resistance of a NiTi alloy by high current pulsed electron beam treatment, Surf. Coat. Technol., 2006, vol. 201, no. 6, pp. 3096–3102. https://doi.org/10.1016/j.surfcoat.2006.06.030

Li, M.C., Hao, S.Z., Wen, H., and Huang, R.F., Surface composite nanostructures of AZ91 magnesium alloy induced by high current pulsed electron beam treatment, Appl. Surf. Sci., 2014, vol. 303, pp. 350–353. https://doi.org/10.1016/j.apsusc.2014.03.004

Uvarov A., Uemura K., Alexandrov S., Murayama H., Soba R., Molecular properties characterization of PTFE films deposited by hot wire CVD, Session Report. 16th Symp. on High Current Electronics and 10th Conference on Materials Modification, Tomsk, 2010, Tomsk, 2010, pp. 500–503.

Batrakov, A.V., Onischenko, S.A., Kurkan, I.K., Rostov, V.V., Yakovlev, E.V., Nefedtsev, E.V., and Tsygankov, R.V., Comparative study of breakdown strength of vacuum insulation in gaps with electron-beam polished electrodes under pulsed DC and microwave electric fields, Proc. 28th Int. Symp. on Discharges and Electrical Insulation in Vacuum, 2018, vol. 1, pp. 77–80. https://doi.org/10.1109/deiv.2018.8537014

Proskurovsky, D.I., Rotshtein, V.P., and Ozur, G.E., Use of low-energy, high-current electron beams for surface treatment of materials, Surf. Coat. Technol., 1997, vol. 96, no. 1, pp. 117–122. https://doi.org/10.1016/S0257-8972(97)00093-5

Cai, J., Lv, P., Guan, Q., Xu, X., Lu, J., Wang, Z., and Han, Z., Thermal cycling behavior of thermal barrier coatings with MCrAlY bond coat irradiated by high-current pulsed electron beam, ACS Appl. Mater. Interfaces, 2016, vol. 47, no. 8, pp. 32541–32556. https://doi.org/10.1021/acsami.6b11129

Ivanov, Yu.F., Gromov, V.E., Grishunin, V.A., Teresov, A.D., and Konovalov, S.V., Surface layer structure and fatigue life of rail steel irradiated by a high-intensity electron beam, Fiz. Mezomekh., 2013, vol. 16, no. 2, pp. 47–53.

Ivanov, Yu.F., Gromov, V.E., Grishunin, V.A., and Konovalov, S.V., Rail steel treated by electron beam, its phase composition, structure, and fatigue life, Vopr. Materialoved., 2013, vol. 73, no. 1, pp. 20–30.

Gromov, V.E., Ivanov, Yu.F., Grishunin, V.A., Raikov, S.V., and Konovalov, S.V., Scale levels of the structure-phase states and fatigue life of rail steel after electron-beam treatment, Usp. Fiz. Met., 2013, vol. 14, no. 1, pp. 67–80.

Gao, B., Hu, L., Li, S.-W., Hao, Y., Zhang, Y.-D., Tu, G.-F., and Grosdidier, T., Study on the nanostructure formation mechanism on the hypereutectic Al–17Si alloy induced by pulsed electron beam, Appl. Surf. Sci., 2015, vol. 346, pp. 147–157. https://doi.org/10.1016/j.apsusc.2015.04.029

Gromov, V.E., Ivanov, Yu.F., Glezer, A.M., Konovalov, S.V., and Alsaraeva, K.V., Structural evolution of silumin treated with a high-intensity pulse electron beam and subsequent fatigue loading up to failure, Bull. Russ. Acad. Sci.: Phys., 2015, vol. 79, pp. 1169–1172. https://doi.org/10.3103/S1062873815090087

Kim, J.S., Lee, W.J., and Park, H.W., The state of the art in the electron beam manufacturing processes, Int. J. Precis. Eng. Manuf., 2016, vol. 17, no. 11, pp. 1575–1585. https://doi.org/10.1007/s12541-016-0184-8

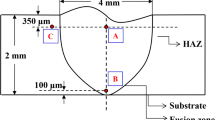

Ivanov, Yu.F., Itin, V.I., Lykov, S.V., Markov, A.B., Rotshtein, V.P., Tukhfatullin, A.A., and Dikii, N.P., Structural analysis of heat-affected zone of steel 45 treated by low-energy high-current electron beam, Fiz. Met. Metalloved., 1993, vol. 75, no. 5, pp. 103–112.

Markov, A.B. and Rotshtein, V.P., Calculation and experimental determination of size of hardening and tempering zones in hardened U7A steel irradiated with a pulsed electron beam, Poverkhnost, 1998, vol. 4, pp. 83–89.

Structure and Properties of Metals at Different Energy Effects and Treatment Technologies, Klimenov, V.A. and Starenchenko, V.A., Eds., Trans. Tech. Publ., 2014, p. 324.

Ivanov, Yu.F., Zagulyaev, D.V., Nevskii, S.A., Gromov, V., Sarychev, V.D., and Semin, A.P., Microstructure and properties of hypoeutectic silumin treated by high-current pulsed electron beams, Progr. Phys. Met., 2019, vol. 20, no. 3, pp. 451–490. https://doi.org/10.15407/ufm.20.03.447

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. Moshkin

About this article

Cite this article

Ivanov, Y.F., Gromov, V.E., Zagulyaev, D.V. et al. Improvement of Functional Properties of Alloys by Electron Beam Treatment. Steel Transl. 52, 71–75 (2022). https://doi.org/10.3103/S0967091222010120

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091222010120