Abstract

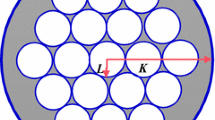

Non-crystalline solids have important applications in engineering and science. To predict the stress-strain behaviour of these materials, this work constructs an efficient strain energy density function using the concepts of molecular interactions. Considering hard contact between molecules, strain energy density of materials is defined in terms of packing fraction (volume occupied by the molecules per unit volume of the material) in deformed configurations. The packing fraction is represented in terms of strain invariants of right Cauchy-Green deformation tensor. Constitutive model obtained from the present strain energy density function is applied for predicting finite deformations of the materials like uniaxial extension, equibiaxial extension, and pure dilation. We observe that increasing reference packing fraction increases the Cauchy stress components. Results obtained from the present theoretical model is compared with experimental results of flexible polyurethane foam materials. We obtain good agreement with the experimental results. The present strain energy density function can be applied for predicting deformation as well as stress-strain behaviour of any other micro/nano components used in engineering systems.

Similar content being viewed by others

REFERENCES

M. L. Falk and C. E. Maloney, “Simulating the mechanical response of amorphous solids using atomistic methods,” Eur. Phys. J. B. 75 (4), 405–413 (2010). https://doi.org/10.1140/epjb/e2010-00157-7

R. Xu and Y. Xu, Modern Inorganic Synthetic Chemistry, 2nd ed. (Elsevier, 2017).

Zb. H. Stachurski, “On structure and properties of amorphous materials,” Mater. 4 (9), 1564–1598 (2011). https://doi.org/10.3390/ma4091564

J. Mort, “Applications of amorphous materials,” Phys. Technol. 11 (4), 134–141 (1980). https://doi.org/10.1088/0305-4624/11/4/I02

A. J. M. Spencer, Continuum Mechanics (Dover Publ., 2004).

R. W. Ogden, “Large deformation isotropic elasticity - on the correlation of theory and experiment for incompressible rubberlike solids,” Proc. Math. Phys. 326 (1567), 565–584 (1972). https://doi.org/10.1098/rspa.1972.0026

M. Mooney, “A theory of large elastic deformation,” J. Appl. Phys. 11 (9), 582–592 (1940). https://doi.org/10.1063/1.1712836

R. S. Rivlin and E. K. Rideal, “Large elastic deformations of isotropic materials IV. further developments of the general theory,” Philos. Trans. Roy. Soc. A 241 (835), 379–397 (1948). https://royalsocietypublishing.org/doi/pdf/10.1098/rsta.1948.0024

A. N. Gent, Engineering with Rubber (Carl Hanser Verlag, Munich, 2001).

W. K. Liu, E G. Karpov, S. Zhang, and H. S. Park, “An introduction to computational nanomechanics and materials,” Comput. Meth. Appl. Mech. Eng. 193, 1529–1578 (2004). https://doi.org/10.1016/j.cma.2003.12.008

D. Garcia-Gonzalez, A. Jrusalem, S. Garzon-Hernandez, et al. “A continuum mechanics constitutive framework for transverse isotropic soft tissues,” J. Mech. Phys. Solids. 112, 209–224 (2018). https://doi.org/10.1016/j.jmps.2017.12.001

D. A. McQuarrie, Statistical Mechanics (Viva Books Private Limited, New Delhi, 2008).

V. K. Devendiran, R. K. Sandeep, K. Kannan, and K. R. Rajagopal, “A thermodynamically consistent constitutive equation for describing the response exhibited by several alloys and the study of a meaningful physical problem,” Int. J. Solids Struct. 108, 1–10 (2017). https://doi.org/10.1016/j.ijsolstr.2016.07.036

N. Sakaguch, M. Niinomi, and T. Akahori, “Tensile deformation behavior of ti-nb-ta-zr biomedical alloys,” Mater. Trans. 45, 1113–1119 (2004). https://doi.org/10.2320/matertrans.45.1113

Y. L. Hao, S. J. Li, S. Y. Sun et al., “Super-elastic titanium alloy with unstable plastic deformation,” Appl. Phys. Lett. 87 (9), 091906 (2005). https://doi.org/10.1063/1.2037192

F.Q. Hou, S.J. Li, Y.L. Hao, and R. Yang, “Nonlinear elastic deformation behaviour of ti-30nb12zr alloys,” Scr. Mater. 63 (1), 54–57 (2010). https://doi.org/10.1016/j.scriptamat.2010.03.011

X. Zhang, Z. Chen, and Y. Liu, The Material Point Method (Academic Press, Oxford, 2017).

D. F. Jones and L. R. G. Treloar, “The properties of rubber in pure homogeneous strain,” J. Phys. D: Appl. Phys. 8 (11), 1285–1304 (1975). https://doi.org/10.1088/0022-3727/8/11/007

P. Steinmann, M. Hossain, and G. Possart, “Hyperelastic models for rubber-like materials: consistent tangent operators and suitability for treloars data,” Arch. Appl. Mech. 82, 1183–1217 (2012). https://doi.org/10.1007/s00419-012-0610-z

B. R. Seth, Generalized Strain Measure with Applications to Physical Problems, MRC Technical Report No. 248 (Math. Res. Center, Medison, 1964).

K. Hashiguchi, Elatoplasticity Theory (Springer-Verlag, Berlin Heidelberg, 2013).

M. Hossain and P. Steinmann, “More hyperelastic models for rubber-like materials: consistent tangent operators and comparative study,” J. Mech. Behav. Mater. 22 (1–2), 27–50 (2013). https://doi.org/10.1515/jmbm-2012-0007

E. M. Arruda and M. C. Boyce, “Evolution of plastic anisotropy in amorphous polymers during finite straining,” Int. J. Plast. 9 (6), 697–720 (1993). https://doi.org/10.1016/0749-6419(93)90034-N

O. Yeoh, “Hyperelastic material models for finite element analysis of rubber,” J. Nat. Rubber Res. 12, 142–153 (1997).

J. Lambert-Diani and C. Rey, “New phenomenological behavior laws for rubbers and thermoplastic elastomers,” Eur. J. Mech. A/Solids 18 (6), 1027–1043 (1999). https://doi.org/10.1016/S0997-7538(99)00147-3

O. Lopez-Pamies, “A new I1-based hyperelastic model for rubber elastic materials,” C. R. - Mec. 338 (1), 3–11 (2010). https://doi.org/10.1016/j.crme.2009.12.007

L. C. S. Nunes, “Mechanical characterization of hyperelastic polydimethylsiloxane by simple shear test,” Mater. Sci. Eng. A. 528 (3), 1799–1804 (2011). https://doi.org/10.1016/j.msea.2010.11.025

P. M. Gullett, M. F. Horstemeyer, M. I. Baskes, and H. Fang, “A deformation gradient tensor and strain tensors for atomistic simulations,” Model. Simul. Mater. Sci. Eng. 16 (1), 015001 (2007). https://doi.org/10.1088/0965-0393/16/1/015001

J. Ghanbari and R. Naghdabadi, “Multiscale nonlinear constitutive modeling of carbon nanostructures based on interatomic potentials,” Comput. Mater. Contin. 10 (1), 41–64 (2009). https://doi.org/10.3970/cmc.2009.010.041

P. M. Morse, “Diatomic molecules according to the wave mechanics. II. Vibrational levels.” Phys. Rev. 34 (1), 57–64 (1929). https://doi.org/10.1103/PhysRev.34.57

J. Li and A. K. Soh, “Modeling of the plastic deformation of nanostructured materials with grain size gradient,” Int. J. Plast. 39, 88–102 (2012). https://doi.org/10.1016/j.ijplas.2012.06.004

B. Vorselaars, A. V. Lyulin, and M. A. J. Michels, “Deforming glassy polystyrene: Influence of pressure, thermal history, and deformation mode on yielding and hardening.” J. Chem. Phys. 130 (7), 074905 (2009). https://doi.org/10.1063/1.3077859

F. Yang, S. Ghosh, and L. J. Lee. “Molecular dynamics simulation based size and rate dependent constitutive model of polystyrene thin films,” Comput. Mech. 50, 169–184 (2012). https://doi.org/10.1007/s00466-012-0714-x

M. Jafari, S. Ziaei-Rad, and N. Nouri, “Modeling of the plastic deformation of polycrystalline materials in micro and nano level using finite element method,” J. Nano Res. 22, 41–60 (2013). https://doi.org/10.4028/www.scientific.net/JNanoR.22.41

A. V. Konovalov, “Constitutive relations for metals under high-temperature plastic strains,” Mech. Solids 44 (1), 98–104 (2009). https://doi.org/10.3103/S0025654409010105

D. L. Bykov, D. N. Konovalov, and V. A. Peleshko, “Constitutive relations for calculating the processes of quasistatic deformation, damage, and fracture of bodies (Including those with concentrators) made of filled polymer materials,” Mech. Solids 46 (6), 839–855 (2011). https://doi.org/10.3103/S0025654411060045

S. Mukherjee and A.K. Mandal, “A generalized strain energy function using fractional powers: Application to isotropy, transverse isotropy, orthotropy, and residual stress symmetry,” Int. J. Non-Lin. Mech. 128, 103617 (2021). https://doi.org/10.1016/j.ijnonlinmec.2020.103617

S. Mukherjee and A. K. Mandal, “Static and dynamic characteristics of a compound sphere using initial stress reference independence,” Int. J. Non-Lin. Mech. 136, 103787 (2021). https://doi.org/10.1016/j.ijnonlinmec.2021.103787

S. Mukherjee and A. K. Mandal, “Extended gent models for residually stressed thick spheres and cylinders,” Int. J. Non-Lin. Mech. 137, 103804 (2021). https://doi.org/10.1016/j.ijnonlinmec.2021.103804

L. Rao V and S. Das, “Drag force on a liquid domain moving inside a membrane sheet surrounded by aqueous medium,” J. Fluid Mech. 779, 468–482 (2015). https://doi.org/10.1017/jfm.2015.434

P. Mahata, A. Shrivastava, C. K. Sahu, et al., “Electrostatic interaction with a rigid curved domain causes nonlinear deformation of a thin elastic sheet: Implications for biosystems,” Phys. B: Condens. Matter. 646, 414274 (2022). https://doi.org/10.1016/j.physb.2022.414274

P. Mahata and L. Vennamneni, “Deformation of an elastic membrane interacting electrostatically with a rigid curved domain: implications to biosystems,” Arch. Appl. Mech. 91, 1–17 (2021). https://doi.org/10.1007/s00419-020-01785-1

P. Mahata and S. Das, “Generation of wavy structure on lipid membrane by peripheral proteins: A linear elastic analysis,” FEBS Lett. 591, 1333–1348 (2017). https://doi.org/10.1002/1873-3468.12661

P. Mahata, L. Singhal, R. Prasad et al., “Computational investigation for deformation of lipid membrane by BAR proteins due to electrostatic interaction,” Mater. Today: Proc. 61, 1–9 (2022).

S. Mukherjee and P. Mahata, “Computational investigation for endocytosis of CoVID-19 virus SARS-CoV-2 in cell membrane,” Proc. Inst. Mech. Eng., Part C 235 (24), 7331–7342 (2021). https://doi.org/10.1177/09544062211029984

F. Lin, J. S. Peng, S. F. Xue, and J. Yang, “An indirect method to determine nonlinear elastic shear stress-strain constitutive relationships for nonlinear torsional deformation of Al-1%Si shaft,” Mech. Solids 57 (5), 1173–1193 (2022). https://doi.org/10.3103/S0025654422050090

N. F. Carnahan and K. E. Starling, “Equation of state for nonattracting rigid spheres,” J. Chem. Phys. 5 1(2), 635–636 (1969). https://doi.org/10.1063/1.1672048

F. Lado, “Equation of state of the hard disk fluid from approximate integral equations,” J. Chem. Phys. 49 (7), 3092–3096 (1968). https://doi.org/10.1063/1.1670553

E. Leutheusser, “Exact solution of the Percus-Yevick equation for a hard-core fluid in odd dimensions,” Phys. A: Stat. Mech. 127 (3), 667–676 (1984). https://doi.org/10.1016/0378-4371(84)90050-5

Y. Song, E. A. Mason, and R. M. Stratt, “Why does the carnahan-starling equation work so well?” J. Phys. Chem. 93, 6916–6919 (1989).

F. H. Ree and W. G. Hoover, “Fifth and sixth virial coefficients for hard spheres and hard disks,” J. Chem. Phys. 40, 939–950 (1964). https://doi.org/10.1063/1.1725286

Y. Song and E. A. Mason, “Statistical-mechanical theory of a new analytical equation of state,” J. Chem. Phys. 91 (12), 7840–7853 (1989). https://doi.org/10.1063/1.457252

P. Mahata and S. L. Das, “Two-dimensional convex-molecule fluid model for surface adsorption of proteins: Effect of soft interaction on adsorption equilibria,” Phys. Rev. E 90 (6), 062713 (2014). https://doi.org/10.1103/PhysRevE.90.062713

J. H. Weiner, Statistical Mechanics of Elasticity, 2nd ed. (Dover Publications, New York, 2017).

W. H. El-Ratal and P. K. Mallick, “Elastic response of flexible polyurethane foams in uniaxial tension,” J. Eng. Mater. Technol.-T. ASME, 118, 157–161 (1996). https://doi.org/10.1115/1.2804881

ACKNOWLEDGMENTS

The authors would like to thank the anonymous referees for their valuable suggestions to enhance the quality of the paper.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Allerton Press remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Kumar, R., Mahata, P. A Strain Energy Density Potential for Non-Crystalline Solids Using Molecular Interactions. Mech. Solids 58, 2097–2114 (2023). https://doi.org/10.3103/S0025654423601052

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654423601052