Abstract

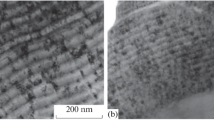

The possibility of formation of nanocrystalline Ti-Al-N coatings using the method of ion-plasma deposition is demonstrated. The mechanical and tribotechnical characteristics of the coatings in comparison with TiN coating are studied. Ti-Al-N nanocomposite coatings possess high hardness (35 GPa) and higher wear resistance and lower wear capacity as compared to TiN coating. For a grain size of 12–15 nm the nanostructural Ti-Al-N coating has the following elemental composition: Ti ≈ 60 at %, N ≈ 30 at %, Al ≈ 10 at %. The phase composition of the coating represents the solid solution (Ti, Al)N. For this elemental and phase composition and nanograin size maximal hardness and elasticity modulus of the coating are found.

Similar content being viewed by others

References

Danilin, B.S. and Syrchin, V.K., Magnetronnye raspylitel’nye sistemy (Magnetron Sputtering Systems), Moscow: Radio i svyaz’, 1982.

Andreev, A.A., Sablev, V.P., Shulaev, V.M., and Grigor’ev, S.N., Vakuumno-dugovye ustroistva i pokrytiya (Vacuum-Arc Devices and Coatings), Kharkov: NNTs “KhFTI”, 2005.

Syrkin, V.G., CSD metod—khimicheskoe parofaznoe osazhdenie (CSD Method—Chemical Vapor Phase Deposition), Moscow: Nauka, 2000.

Beresnev, V.M., Pogrebnyak, A.D., Shpak, A.V., Azarenkov, N.A., et al., Structure, Properties and Synthesis of Hard Nanocrystalline Coatings Deposited by Different Methods, Usp. Fiz. Met., 2007, no. 3, pp. 171–246.

Pogrebnyak, A.D., Shpak, A.V., Azarenkov, N.A., and Beresnev, V.M., Structure and Properties of Hard and Superhard Nanocomposite Coatings, Usp. Fiz. Nauk, 2009, vol. 179, no. 1, pp. 35–64.

Sergeev, V.P., Fedorishcheva, M.V., Voronov, A.V., et al., Tribomechanical Properties and Structure of Ti1−x AlxN Nanocomposite Coatings, Izv. Tomsk. Politekhn. Univ., 2006, vol. 309, no. 2, pp. 149–153.

Levashov, E.A. and Shtanskii, D.V., Multifunctional Nanostructured Films, Usp. Khim., 2007, vol. 76, no. 5, pp. 501–509.

Veprek, S., Maritza, G.J., Veprek-Heijman, M.G.J., Karvankova, P., and Prochazka, J., Different Approaches to Superhard Coatings and Nanocomposites, Thin Solid Films, 2005, vol. 476, pp. 1–29.

Musil, J. and Hruby, H., Superhard Nanocomposite Ti1 − x AlxN Films Prepared by Magnetron Sputtering, Thin Solid Films, 2000, vol. 65, pp. 104–109.

Shpak, A.P., Cheremskoi, P.G., Kunitskii, Yu.A., and Sobol’, O.V., Klasternye i nanostrukturnye materialy (Cluster and Nanostructured Materials), Kiev: ID “Akademperiodika”, 2005, vol. 3.

Sobol’, O.V., Forming Mechanism of Condensates Phase-Structural State, Fiz. Inzhener. Poverkhn., 2008, vol. 6, no. 3, pp. 515–519.

Patscheider, J., Nanocomposite Hard Coatings for Wear Protections, MRS Bull., 2003, vol. 28, no. 3, pp. 180–183.

Tolok, V.T., Shets, O.M., Lymar’, V.F., Beresnev, V.M., Gritsenko, V.I., and Krivonos, M.G., RF Patent no. 1757249, MKI C23 c14/00/, Byull. Izobret., 1993, no. 18, p. 7.

Beresnev, V.M., Tolok, V.T., Shvets, O.M., et al., Micro-Nanolayered Coatings Formed by Vacuum-Arc Deposition Using the High-Frequency Discharge, Fiz. Inzhener. Poverkhn., 2006, vol. 4, nos. 1–2, pp. 93–97.

Beresnev, V.M., Shvets, O.M., and Belyaeva, T.N., Features of High-Frequency Energy Input into Metallic Plasma Flow, Fiz. Inzhener. Poverkhn., 2005, vol. 3, nos. 1–2, pp. 37–39.

Pelleg, J., Zevin, L.Z., Lungo, S., and Croitaru, N., Reactive-Sputter-Deposition TiN Films on Glass Substrates, Thin Solid Films, 1991, vol. 197, pp. 117–128.

Azarenkov, N.A., Beresnev, V.M., and Pogrebnyak, A.D., Struktura i svoistva zashchitnykh pokrytii i modifitsirovannykh sloev (Structure and Properties of Protective Coatings and Modified Layers), Kharkov: Khrarkovskii natsional’nyi univ., 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.M. Beresnev, A.D. Pogrebnyak, P.V. Turbin, S.N. Dub, G.V. Kirik, M.K. Kylyshkanov, O.M. Shvets, V.I. Gritsenko, A.P. Shipilenko, 2010, published in Trenie i Iznos, 2010, Vol. 31, No. 5, pp. 467–474.

About this article

Cite this article

Beresnev, V.M., Pogrebnyak, A.D., Turbin, P.V. et al. Tribotechnical and mechanical properties of Ti-Al-N nanocomposite coatings deposited by the ion-plasma method. J. Frict. Wear 31, 349–355 (2010). https://doi.org/10.3103/S1068366610050053

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366610050053