Abstract

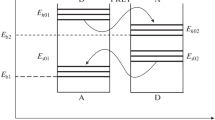

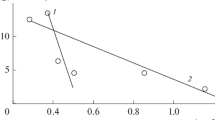

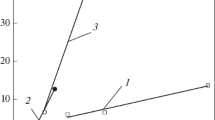

As a result of studying the mechanism of polishing the polymer optical materials with disperse systems composed of micro- and nanoparticles of polishing powders, it has established that the energy of sludge and wear particles during the resonant transfer of energy from the disperse phase particles of a polishing disperse system to a treated surface and backward is inversely proportional to the spectral separation between them. It has been shown that the energies of sludge and wear particles are decreased during the polishing of polymer materials with a disperse system of nanopowders by 5 time with an increase in the spectral separation from 27 to 78 cm–1 and from 17 to 24 cm–1, respectively. When polishing is performed with the disperse system of micropowders, their energies are decreased by 2–5 times with an increase in the spectral separation from 8 to 95 cm–1 and from 16 to 57 cm–1. When the spectral separation between a treated material and a polishing powder is decreased, the volumes of sludge and wear particles and, correspondingly, the polishing efficiency and grows alongside with the intensity of wear on the disperse phase particles of the disperse system. It has been found that the polishing efficiency strongly depends on the efficiency of the Forster resonant energy transfer and grows with a decrease in the product of the ratios between the vibration frequencies of molecular moieties on the surface of polishing powder particles and the treated surface and an increase in the ratio between the lifetimes of treated surface clusters and clusters of polishing powder particles in an excited state. It has been shown that the results of theoretical calculations on the performance efficiency of polishing the optical materials coincides with experimental results with a deviation of 1–8%.

Similar content being viewed by others

REFERENCES

Filatov, Y.D., Polishing of precision surfaces of optoelectronic device elements made of glass, sitall, and optical and semiconductor crystals: A review, J. Superhard Mater., 2020, vol. 42, no. 1, pp. 30–48.

Filatov, O.Yu., Sidorko, V.I., Kovalev, S.V., Filatov, Y.D., and Vetrov, A.G., Material removal rate in polishing anisotropic monocrystalline materials for optoelectronics, J. Superhard Mater., 2016, vol. 38, no. 2, pp. 123–131.

Filatov, O.Yu., Sidorko, V.I., Kovalev, S.V., Filatov, Y.D., and Vetrov, A.G., Polishing substrates of single crystal silicon carbide and sapphire for optoelectronics, Funct. Mater., 2016, vol. 23, no. 1, pp. 104–110.

Filatov, Yu.D., Filatov, A.Yu., Syrota, O.O., Yashchuk, V.P., Monteil, G., Heisel, U., and Storchak, M., The influence of tool wear particles scattering in the contact zone on the workpiece surface microprofile formation in polishing quartz, J. Superhard Mater., 2010, vol. 32, no. 6, pp. 415–422.

Filatov, O.Yu., Sidorko, V.I., Kovalev, S.V., Filatov, Yu.D., and Vetrov, A.G., Polished surface roughness of optoelectronic components made of monocrystalline materials, J. Superhard Mater., 2016, vol. 38, no. 3, pp. 197–206.

Suratwala, T.I., Materials Science and Technology of Optical Fabrication, Hoboken: Wiley, 2018.

Sato, N., Aoyama, Y., Yamanaka, J., Toyotama, A., and Okuzono, T., Particle adsorption on hydrogel surfaces in aqueous media due to van der Waals attraction, Sci. Rep., 2017, vol. 7, 6099.

Lin, G., Guo, D., Xie, G., Jia, Q., and Pan, G., In situ observation of colloidal particle behavior between two planar surfaces, Colloids Surf., A, 2015, vol. 482, pp. 656–661.

Filatov, Yu.D., Mechanism of surface microrelief formation during glass treatment, Sverkhtverd. Mater., 1991, vol. 13, no. 5, pp. 63–67.

Filatov, Yu.D. and Rogov, V.V., A cluster model of mechanism of silica-containing material fatigue wear in polishing. Part 1, Sverkhtverd. Mater., 1994, vol. 16, no. 3, pp. 40–43.

Filatov, Yu.D., Polishing of aluminosilicate materials with tools with bound polishing powder, Sverkhtverd. Mater., 2001, vol. 23, no. 3, pp. 32–42.

Filatov, Y.D., Filatov, O.Y., Monteil, G., Heisel, U., and Storchak, M.G., Bound-abrasive grinding and polishing of surfaces of optical materials, Opt. Eng., 2011, vol. 50, no. 6, 063401.

Cardullo, R.A., Principles of non-radiative FRET: The spectroscopic ruler, Microsc. Anal., 2002, vol. 88, pp. 19–21.

Wang, Yu. and Wang Lihong, V., Forster resonance energy transfer photoacoustic microscopy, J. Biomed. Opt., 2012, vol. 17, no. 8, 086007.

Egorova, A.V., Leonenko, I.I. Aleksandrova, D.I., Skripinets, Yu.V., and Antonovich, V.P., Non-radiative transfer of electronic excitation energy from the Sm(III) complex to the cyanine dye Cy5, Vestn. Odess. Nats. Univ. Khim., 2015, vol. 20, no. 3 (55), pp. 47–55.

Liu, F., Rodina, A.V., Yakovlev, D.R., Golovatenko, A.A., Greilich, A., Vakhtin, E.D., Susha, A., Rogach, A.L., Kusraev, Y.G., and Bayer, M., Förster energy transfer of dark excitons enhanced by a magnetic field in an ensemble of CdTe colloidal nanocrystals, Phys. Rev. B, 2015, vol. 92, 125403.

Poddubny, A.N. and Rodina, A.V., Nonradiative and radiative forster energy transfer between quantum dots, J. Exp. Theor. Phys., 2016, vol. 122, no. 3, pp. 531–538.

Zabolotskii, A.A., Resonance energy transfer between a spherical nanoparticle and a J-aggregate, Optoelectron. Instrum. Data Process., 2017, vol. 53, no. 3, pp. 81–88.

Mikhailov, T.N., Evropeitsev, E.A., Belyaev, K.G., Toropov, A.A., Rodina, A.V., Golovatenko, A.A., Ivanov, S.V., Pozina, G., and Shubina, T.V., Förster energy transfer in arrays of epitaxial CdSe/ZnSe quantum dots involving bright and dark excitons, Phys. Solid State, 2018, vol. 60, no. 8, pp. 1590–1594.

Jones, G.A. and Bradshaw, D.S., Resonance energy transfer: From fundamental theory to recept applications, Front. Phys., 2019, vol. 7, 100.

Khrebtov, A.I., Reznik, R.R., Ubyivovk, E.V., Litvin, A.P., Skurlov, I.D., Parfenov, P.S., Kulagina, A.S., Danilov, V.V., and Cirlin, G.E., Nonradiative energy transfer in hybrid nanostructures with varied dimensionality, Semiconductors, 2019, vol. 53, no. 9, pp. 1258–1261.

Singldinger, A., Gramlich, M., Gruber, C., Lampe, C., and Urban, A.S., Nonradiative energy transfer between thickness-controlled halide perovskite nanoplatelets, ACS Energy Lett., 2020, vol. 5, pp. 1380–1385.

Abeywickrama, Ch., Premaratne, M., and Andrews, D.L., Analysis of Förster resonance energy transfer (FRET) in the vicinity of a charged metallic nanospere via nonlocal, Proc. SPIE, Nanophotonics VIII, 2020, 113451B.

Cortes, C.L. and Jacob, Z., Fundamental figures of merit for engineering Förster resonance energy transfer, Opt. Express, 2018, vol. 26, no. 15, pp. 19371–19387.

Gordon, F., Elcoroaristizabal, S., and Ryder, A.G., Modelling Förster resonance energy transfer (FRET) using anisotropy resolved multi-dimensional emission spectroscopy (ARMES), Biochim. Biophys. Acta, Gen. Subj., 2021, vol. 1865, no. 2, 129770.

Du, M., Martinez-Martinez, L.A., Ribeiro, R.F., Hu, Z., Menon, V., and Yuen-Zhou, J., Theory for polariton-assisted remote energy transfer, Chem. Sci., 2018, vol. 9, pp. 6659–6669.

Zhong, X., Chervy, T., Zhang, L., Thomas, A., George, J., Genet, C., Hutchison, J.A., and Ebbesen, T.W., Energy transfer between spatially separated entangled molecules, Angew. Chem., Int. Ed., 2017, vol. 56, no. 31, pp. 9034–9038.

Dovzhenko, D., Lednev, M., Mochalov, K., Vaskan, I., Rakovich, Yu., and Nabiev, I., Polariton-assisted manipulation of energy relaxation pathways: Donor–acceptor role reversal in a tuneable microcavity, Chem. Sci., 2021, vol. 12, pp. 12794–12805.

Nabiev, I., Strong light-matter coupling for optical switching through the fluorescence and FRET control, J. Phys.: Conf. Ser., 2021, vol. 2058, 012001.

Filatov, Y.D., Sidorko, V.I., Boyarintsev, A.Y., Kovalev, S.V., and Kovalev, V.A., Transfer energy in the interaction of an optical surface with a polishing disperse system, J. Superhard Mater., 2022, vol. 44, no. 2, pp. 117–126.

Serova, V.N., Polimernye opticheskie materialy (Polymer Optical Materials), St. Petersburg: Nauchnye Osnovy i Tekhnologii, 2011.

Mathur, V. and Sharma, K., Thermal response of polystyrene/poly methyl methacrylate (PS/PMMA) polymeric blends, Heat Mass Transfer, 2016, vol. 52, pp. 2901–2911.

Guide to the identification of microplastics by FTIR and Raman spectroscopy, Plast. Massy, 2020, nos. 7–8, pp. 23–27.

Eissa, M.F., Effect of transferred electronic energy density on optical, electrical and structural properties of polyallyl-diglycol carbonate (CR-39) polymer, J. Macromol. Sci., Part B, 2014, vol. 53, no. 3, pp. 529–540.

Abdul-Kader, A.M., Zaki, M.F., and El-Badry Basma, A., Modified the optical and electrical properties of CR-39 by gamma ray irradiation, J. Radiat. Res. Appl. Sci., 2014, vol. 7, no. 3, pp. 286–291.

Zhang, H.Q., Jin, Y., and Qiu1, Y., The optical and electrical characteristics of PMMA film prepared by spin coating method, IOP Conf. Ser.: Mater. Sci. Eng., 2015, vol. 87, pp. 1–5.

Ashry, A.H., Abou-Leila, M., and Abdalla, A.M., Detection efficiency of alpha particles in CR-39 nuclear track detector: Experimental study, Adv. Sci., Eng. Med., 2012, vol. 4, no. 4, pp. 341–344.

Filatov, Y.D., Sidorko, V.I., Kovalev, S.V., and Kovalev, V.A., Effect of the rheological properties of a dispersed system on the polishing indicators of optical glass and glass ceramics, J. Superhard Mater., 2021, vol. 43, no. 1, pp. 65–73.

Filatov, Y.D., Sidorko, V.I., Kovalev, S.V., and Kovalev, V.A., Effect of interaction between polishing powder particles and a treated material on polishing characteristics of optical surfaces, J. Superhard Mater., 2021, vol. 43, no. 4, pp. 296–302.

Filatov, Yu.D., Diamond polishing of crystalline materials for optoelectronics, J. Superhard Mater., 2017, vol. 39, no. 6, pp. 427–433.

Filatov, Yu.D., Sidorko, V.I., Filatov, A.Yu., Yashuk, V.P., Heisel, W., and Storchak, M., Surface quality control in diamond abrasive finishing, in Optical Measurement Systems for Industrial Inspection VI, Proc. SPIE, 2009, vol. 7389, 73892O.

Filatov, Yu.D., Sidorko, V.I., Filatov, O.Yu., Kovalev, S.V., Heisel, U., and Storchak, M., Surface roughness in diamond abrasive finishing, J. Superhard Mater., 2009, vol. 31, no. 3, pp. 191–195.

Filatov, Yu. D., Yashchuk, V. P., Filatov, A. Yu., Heisel, U., Storchak, M., and Monteil, G., Assessment of surface roughness and reflectance of nonmetallic products upon diamond abrasive finishing, J. Superhard Mater., 2009, vol. 31, no. 5, pp. 338–346.

Babitha, K.K., Sreedevi, A., Priyanka, K.P., et al., Structural characterization and optical studies of CeO2 nanoparticles synthesized by chemical precipitation, Indian J. Pure Appl. Phys., 2015, vol. 53, pp. 596–603.

Fang, J.F., Xuan, Y.M., and Li, Q., Preparation of polystyrene spheres in different particle sizes and assembly of the PS colloidal crystals, Sci. China: Technol. Sci., 2010, vol. 53, no. 11, pp. 3088–3093.

Hadi Al-Kadhemy, M.F., Rasheed, Z.S., and Salim, S.R., Fourier transform infrared spectroscopy for irradiation coumarin doped polystyrene polymer films by alpha ray, J. Radiat. Res. Appl. Sci., 2016, vol. 9, no. 3, pp. 321–331.

Luo, Q., Zeng, S., Shu, Y., Fu, Z., Zhaoc, H., and Su, S., A novel green process for tannic acid hydrolysis using an internally sulfonated hollow polystyrene sphere as catalyst, RSC Adv., 2018, vol. 8, pp. 17151–17158.

Herman, V., Takacs, H., Duclairoir, F., Renault, O., Tortai, J.H., and Viala, B., Core double-shell cobalt/graphene/polystyrene magnetic nanocomposites synthesized by in situ sonochemical polymerization, RSC Adv. J. Name, 2015, no. 63, pp. 51371–51381.

Analiz polimernykh kompozitsionnykh materialov (Analysis of Polymer Composite Materials), Romanova, N.V., Shafigullin, L.N., Gumerov, I.F., and Gumerov, M.I., Eds., Naberezhnye Chelny: Kazan. Fed. Univ., 2017.

Aziz, Sh.B., Abdullah, O.Gh., Hussein, Ah.M., and Ahmed, H.M., From insulating pmma polymer to conjugated double bond behavior: Green chemistry as a novel approach to fabricate small band gap polymers, Polymers, 2017, vol. 9, no. 11, 626.

Tommasini, F.J., da Cunha Ferreira, L., Tienne, L.G.P., de Oliveira Aguiarb, V., da Silva, M.H.P., da Mota Rocha, L.F., and de Fátima Vieira Marquesb, M., Poly (methyl methacrylate)–SiC nanocomposites prepared through in situ polymerization, Mater. Res., 2018, vol. 21, no. 6, 20180086.

Sayyah, S.M., El-Shafiey, Z.A., Barsoum, B.N., and Khaliel, A.B., Infrared spectroscopic studies of poly(methyl methacrylate) doped with a new sulfur-containing ligand and its cobalt(II) complex during γ-radiolysis, Appl. Polym. Sci., 2003, vol. 91, no. 3, pp. 1937–1950.

Al-Jobouri, H.A., Jber, N.R., Al-Shukrawi, A.H., and Hamid, M.K., Physiochemical properties of crystalline etch products for CR-39 track detector after α-particles irradiation, Adv. Appl. Sci. Res., 2013, vol. 4, no. 4, pp. 501–507.

Zaki, M.F., Elshaer, Y.H., and Taha, D.H., Studying the structural, optical, chemical and electrochemical etching changes of CR-39 for dosemetric applications, Radiat. Prot. Dosim., 2017, vol. 177, no. 3, pp. 272–279.

Jain, R.K., Kumar, A., Chakraborty, R.N., ans Singh, B.K., FTIR spectra of UV induced CR-39 plastic detector, Proc. DAE-BRNS Symp. on Nucl. Phys., 2016, vol. 61, pp. 1006–1007.

Yamauchi, T., Nakai, H., Somaki, Y., and Oda, K., Formation of CO2 gas and OH groups in CR-39 plastics due to gamma-ray and ions irradiation, Radiat. Meas., 2003, vol. 36, nos. 1–6, pp. 99–103.

Filatov, Y.D., Sidorko, V.I., Boyarintsev, A.Y., Kovalev, S. V., Garachenko, V.V., and Kovalev, V.A., Effect of the spectroscopic parameters of the processed material and polishing powder on the parameters of polishing of optical surfaces, J. Superhard Mater., 2022, vol. 44, no. 1, pp. 37–45.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by E. Glushachenkova

About this article

Cite this article

Filatov, Y.D., Sidorko, V.I., Boyarintsev, A.Y. et al. Performance Efficiency of the Polishing of Polymer Optical Materials. J. Superhard Mater. 44, 358–367 (2022). https://doi.org/10.3103/S1063457622050021

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457622050021