Abstract

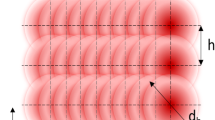

The increasing demand for micro-parts and miniaturization of devices has led to development of manufacturing micro-holes on different materials. In this study, micro-hole arrays were drilled on a CVD diamond film using a nanosecond pulsed laser. The effect of laser processing parameters, such as pulse width, scanning speed, and scanning times on the shape, size, and morphology of micro-holes was investigated. The entrance, exit, and cross-sectional dimensions and morphology of the micro-holes were examined. The results demonstrated that micro-hole arrays with an entrance diameter of 49.1–56.3 μm, exit diameter of 4.6–10.6 μm, and taper angle of less than 18.5° can be obtained using a nanosecond pulsed laser. It was found that pulse width has little effect on entrance diameter, however, with the increase of pulse width, the micro-hole exit diameter and depth increased, while the taper angle decreased. With the increase of laser scanning speed, the micro-hole entrance diameter decreased slightly, and there is little variation in micro-hole exit diameter and taper angle. The scanning times were found to have little effect on micro-hole entrance diameter. However, with the increase of scanning times, the micro-hole exit diameter increased and the taper angle decreased.

Similar content being viewed by others

REFERENCES

Fu, Y., Miyamoto, T., Natsu, W., Zhao, W., and Yu, Z., Study on influence of electrode material on hole drilling in micro-EDM, Procedia CIRP, 2016, vol. 42, pp. 516–520.

Reddy, S., He, L., and Ramakrishana, S., Miniaturized-electroneurostimulators and self-powered/rechargeable implanted devices for electrical-stimulation therapy, Biomed. Signal Process. Contol, 2018, vol. 41, pp. 255–263.

Hasan, M., Zhao, J., and Jiang, Z., A review of modern advancements in micro drilling techniques, J. Manuf. Process., 2017, vol. 29, pp. 343–375.

Zhang, L., Tong, H., and Li, Y., Precision machining of micro tool electrodes in micro EDM for drilling array micro holes, Precis. Eng., 2015, vol. 39, pp. 100–106.

Ren, Z.H., Zheng, X.H., An, Q.L., Wang, C.Y., and Chen, M., Tool breakage feature extraction in PCB micro hole drilling using vibration signals, Adv. Mater., 2012, vol. 497, pp. 126–131.

Rahman, Z., Das, A.K., and Chattopadhyaya, S., Microhole drilling through electrochemical processes: A review, Mater. Manuf. Process., 2008, vol. 33, no. 13, pp. 1379–1405.

Aziz, M., Ohnishi, O., and Onikura, H., Novel micro deep drilling using micro long flat drill with ultrasonic vibration, Precis. Eng., 2012, vol. 36, no. 1, pp. 168–174.

Ahn, Y. and Lee, S.H., Classification and prediction of burr formation in micro drilling of ductile metals, Int. J. Prod. Res., 2017, vol. 55, no. 17, pp. 4833–4846.

Zhang, R., Li, W., Liu, Y., Wang, C., Wang, J., Yang, X., and Cheng, L., Machining parameter optimization of C/SiC composites using high power picosecond laser, Appl. Surf. Sci., 2015, vol. 330, pp. 321–331.

Saxena, K.K., Qian, J., and Reynaerts, D., A review on process capabilities of electrochemical micromachining and its hybrid variants, Int. J. Mach. Tools Manuf., 2018, vol. 127, pp. 28–56.

Elsiti, N.M., Noordin, M.Y., and Alkali, A.U., Fabrication of high aspect ratio micro electrode by using EDM, IOP Conf. Ser.: Mater. Sci. Eng., 2016, vol. 114, no. 1, 012046.

Nitta, K., Inazawa, S., Okada, K., Nakajima, H., Nohira, T., and Hagiwara, R., Analysis of tungsten film electrodeposited from a ZnCl2–NaCl–KCl melt, Electrochim. Acta, 2017, vol. 53, no. 1, pp. 20–23.

He, J.F., Guo, Z.N., Lian, H.S., Liu, J.W., Yao, Z., and Deng, Y., Experiments and simulations of micro-hole manufacturing by electrophoresis-assisted micro-ultrasonic machining, J. Mater. Process. Technol., 2019, vol. 264, pp. 10–20.

Meijer, J., Laser beam machining (LBM), state of the art and new opportunities, J. Mater. Process. Technol., 2004, vol. 149, nos. 1–3, pp. 2–17.

Mishra, S. and Yadava, V., Laser beam micromachining (LBMM)—A review, Opt. Laser Eng., 2015, vol. 73, pp. 89–122.

Sui, T.Y., Cui, Y.X., Lin, B., and Zhang, D.W., Influence of nanosecond laser processed surface textures on the tribological characteristics of diamond films sliding against zirconia bioceramic, Ceram. Int., 2018, vol. 44, no. 18, pp. 23137–23144.

Ito, S., Nagai, M., Matsumoto, T., Inokuma, T., and Tokuda, N., Self-separation of freestanding diamond films using graphite interlayers precipitated from C-dissolved Ni substrates, J. Cryst. Growth, 2017, vol. 470, pp. 104–107.

Feng, W., Lu, W., Zhou, H., Yang, B., and Zuo, D., Surface characterization of diamond film tool grinding on the monocrystal sapphire under different liquid environments, Appl. Surf. Sci., 2016, vol. 387, pp. 784–789.

Badzian, A., Diamond challenged by hard materials: A reflection on developments in the last decades, Mater. Chem. Phys., 2001, vol. 72, pp. 110–113.

Jia, X., Huang, N., Guo, Y., Liu, L., Li, P., Zhai, Z., Yang, B., Yuan, Z., Shi, D., and Jiang, X., Growth behavior of CVD diamond films with enhanced electron field emission properties over a wide range of experimental parameters, J. Mater. Sci. Technol., 2018, vol. 34, no. 12, pp. 2398–2406.

Xu, H., Zang, J., Tian, P., Wang, Y., Yu, Y., Lu, J., Xu, X., and Zhang, P., Rapid grinding CVD diamond films using corundum grinding wheels containing iron, Int. J. Refract. Met. Hard Mater., 2018, vol. 71, pp. 147–152.

Sun, F.H., Zhang, Z.M., Chen, M., and Shen, H.S., Fabrication and application of high quality diamond-coated tools, J. Mater. Process. Technol., 2002, vol.129, nos. 1–3, pp. 435–440.

Nazari, M., Hancock, B.L., Anderson, J., Hobart, K.D., Feygelson, T.I., Tadjer, M.J., Pate, B.B., Anderson, T.J., Piner, E.L., and Holtz, M.W., Optical characterization and thermal properties of CVD diamond films for integration with power electronics, Solid-State Electron., 2017, vol. 136, pp. 12–17.

Yan, X., Wei, J., An, K., Zhao, Y., Liu, J., Chen, L., Hei, L., and Li, C., Quantitative study on graphitization and optical absorption of CVD diamond films after rapid heating treatment, Diamond Relat. Mater., 2018, vol. 87, pp. 267–273.

Luo, D., Nakata, K., Fujishima, A., and Liu, S., Photochemistry and photo-electrochemistry on synthetic semiconducting diamond, J. Photochem. Photobiol., C, 2017, vol. 31, pp. 139–152.

Ohfuji, H., Okuchi, T., Odake, S., Kagi, H., Sumiya, H., and Irifune, T., Micro-/nanostructural investigation of laser-cut surfaces of single- and polycrystalline diamonds, Diamond Relat. Mater., 2010, vol. 19, nos. 7–9, pp. 1040–1051.

Windholz, R. and Molian, P. A., Nanosecond pulsed excimer laser machining of chemically vapour-deposited diamond and graphite: Part II. Analysis and modeling, J. Mater. Sci., 1998, vol. 33, no. 2, pp. 523–528.

Strekalov, V.N., Konov, V.I., Kononenko, V.V., and Pimenov, S.M., Early stages of laser graphitization of diamond, Appl. Phys. A, 2003, vol. 76, no. 4, pp. 603–607.

Picollo, F., Rubanov, S., Tomba, C., Battiato, A., Enrico, E., Perrat-Mabilon, A., Peaucelle, C., Tran Thi, T.N., Boarino, L., Gheeraert, E., and Olivero, P., Effects of high-power laser irradiation on sub-superficial graphitic layers in single-crystal diamond, Acta Mater., 2016, vol. 103, pp. 665–671.

Butler-Smith, P.W., Axinte, D.A., Pacella, M., and Fay, M.W., Micro/nanometric investigations of the effects of laser ablation in the generation of micro-tools from solid CVD diamond structures, J. Mater. Process. Technol., 2013, vol. 213, no. 2, pp. 194–200.

Lin, J.F., Lin, J.W., and Wei, P.J., Thermal analysis for graphitization and ablation depths of diamond films, Diamond Relat. Mater., 2006, vol. 15, no. 1, pp. 1–9.

Guo, B., Zhao, Q., and Fang, X., Precision grinding of optical glass with laser micro-structured coarse-grained diamond wheels, J. Mater. Process. Technol., 2014, vol. 214, no. 5, pp. 1045–1051.

Kononenko, T. V., Ralchenko, V.G., Vlasov, I.I., Garnov, S.V., and Konov, V.I., Ablation of CVD diamond with nanosecond laser pulses of UV–IR range, Diamond Relat. Mater., 1998, vol. 7, nos. 11–12, pp. 1623–1627.

Kononenko, T.V., Komlenok, M.S., Pashinin, V.P., Pimenov, S.M., Konov, V.I., Neff, M., Romano, V., and Lüthy, W., Femtosecond laser microstructuring in the bulk of diamond, Diamond Relat. Mater., 2009, vol. 18, nos. 2–3, pp. 196–199.

Odake, S., Ohfuji, H., Okuchi, T., Kagi, H., Sumiya, H., and Irifune, T., Pulsed laser processing of nano-polycrystalline diamond: A comparative study with single crystal diamond, Diamond Relat. Mater., 2009, vol. 18, nos. 5–8, pp. 877–880.

Kononenko, T.V., Konov, V.I., Garnov, S.V., Klimentov, S.M., and Dausinger, F., Dynamics of deep short pulse laser drilling: Ablative stages and light propagation, Laser Phys., 2001, vol. 11, no. 3, pp. 343–351.

Marimuthu, S., Dunleavey, J., Liu, Y., Smith, B., Kiely, A., and Antar, M., Characteristics of hole formation during laser drilling of SiC reinforced aluminum metal matrix composites, J. Mater. Process. Technol., 2019, vol. 271, pp. 554–567.

Hanon, M.M., Akman, E., Oztoprak, B.G., Gunes, M., Taha, Z.A., Hajim, K.I., Kacar, E., Gundogdu, O., and Demir, A., Experimental and theoretical investigation of the drilling of alumina ceramic using Nd:YAG pulsed laser, Opt. Laser Technol., 2012, vol. 44, no. 4, pp. 913–922.

Mishra, S. and Yadava, V., Modeling of hole taper and heat affected zone due to laser beam percussion drilling, Mach. Sci. Technol., 2013, vol. 17, no. 2, pp. 270–291.

Wu, M., Guo, B., Zhao, Q., He, P., Zeng, Z., and Zang. J., The influence of the ionization regime on femtosecond laser beam machining mono-crystalline diamond, Opt. Laser Technol., 2018, vol. 106, pp. 34–39.

Li, L., Low, D.K.Y., Ghoreshi, M., and Crookall, J.R., Hole taper characterization and control in laser percussion drilling, CIRP Ann., 2002, vol. 51, no. 1, pp. 153–156.

Zhang, Z., Zhang, Q., Wang, Q., Su, H., Fu, Y., and Xu, J., Investigation on the material removal behavior of single crystal diamond by infrared nanosecond pulsed laser ablation, Opt. Laser Technol., 2020, vol. 126, 106086

Das, D.K. and Pollock, T.M., Femtosecond laser machining of cooling holes in thermal barrier coated CMSX4 superalloy, J. Mater. Process. Technol., 2009, vol. 209, nos. 15–16, pp. 5661–5668.

Dou, J., Sun, Y., Xu, M., Cui, J., Mei, X., Wang, W., and Wang, X., Process research on micro-machining diamond microgroove by femtosecond laser, Integr. Ferroelectr., 2019, vol. 198, no. 1, pp. 9–19.

Nawaz, S., Awan, M.B., Saeed, B., and Abbas, N., Experimental investigation of taper angle during millisecond laser drilling of 18CrNi8 steel under multiple parameters and defocused plane, Mater. Res. Express, 2019, vol. 6, no. 8, 086531.

Funding

The authors acknowledge the financial support of the National Natural Science Foundation of China (NSFC) with Grant nos. 51775118 and 51275096.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Yanling Liao, Zhang, F., Wang, P. et al. Experimental Study on Fabricating Micro-Hole Arrays on CVD Diamond Film Using a Nanosecond Pulsed Laser. J. Superhard Mater. 43, 248–260 (2021). https://doi.org/10.3103/S1063457621040067

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457621040067