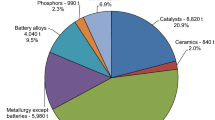

Abstract—The properties, application, and methods for producing titanium and vanadium carbides are considered. These carbides are oxygen-free refractory metal-like compounds. As a result, they are characterized by high values of thermal and electrical conductivity. Their hardness is relatively high. Titanium and vanadium carbides exhibit significant chemical resistance in aggressive environments. For these reasons, they have found application in modern technology. These carbides are used as surfacing materials for the application of wear-resistant coatings to steel products. It is possible to use them as catalysts in organic synthesis. Titanium carbide is used in tungsten-free hard alloys and carbide steels. Due to its high hardness, it is used as an abrasive and as a component of ceramic cutting tools. Vanadium carbide serves as an inhibitor of the growth of tungsten carbide grains in hard alloys. The properties of refractory compounds depend on the content of impurities and dispersion (particle size). To solve a specific problem associated with the use of refractory compounds, it is important to choose the right method for their preparation and to determine the permissible content of impurities in the initial components. This leads to existence of different methods for the synthesis of carbides. The main methods for their preparation are: synthesis from simple substances (metals and carbon), metallothermal and carbothermal reduction. Plasma-chemical synthesis (vapor-gas phase deposition) is also used to obtain carbide nanopowders. A characteristic is given to each of these methods. Information on the possible mechanism of the processes of carbothermal synthesis is presented.

Similar content being viewed by others

REFERENCES

Diagrammy sostoyaniya dvoinykh metallicheskikh system. Spravochnik (State Diagrams of Binary Metal Systems: Reference Book), Moscow: Mashinostroenie, 1996, vol. 1.

Vinitskii, I.M., Dependence of properties of monocarbides of IV–V groups transition metals on carbon content, Poroshk. Metall., 1993, no. 6, pp. 76–82.

Svoistva, poluchenie i primenenie tugoplavkikh soedinenii. Spravochnik (Properties, Manufacture, and Application of Refractory Compounds), Kosolapova, T.Ya., Ed., Moscow: Metallurgiya, 1986.

Kosolapova, T.Ya., Karbidy (Carbides), Moscow: Metallurgiya, 1968.

Doron’kin, E.D., Tungsten-free hard alloys, Tsvetn. Met., 1983, no. 7, pp. 45–46.

Kiparisov, S.S., Levinskii, Yu.V., and Petrov, A.P., Karbid titana. Poluchenie, svoistva, primenenie (Titanium Carbide: Production, Properties, and Application), Moscow: Metallurgiya, 1987.

Kul’kov, S.N. and Gnyusov, S.F., Karbidostali na osnove karbidov titana i vol’frama (Carbide Steels Based on Titanium and Tungsten Carbides), Tomsk: Izd-vo NTL, 2006.

Svistun, L.I., Constructional carbide steels: A review of their fabrication, properties, and application, Russ. J. Non-Ferrous Met., 2009, vol. 51, no. 2, pp. 188–196. https://doi.org/10.3103/S1067821210020215

Samsonov, G.V. and Epik, A.P., Tugoplavkie pokrytiya (Refractory Coatings), Moscow: Metallurgiya, 1973.

Antsiferov, V.N., Shmakov, A.M., Ivanova, M.V., and Popov, V.V., Cladding of titanium carbide powders with a Ni–Fe–P layer and properties of plasma coatings from them. II. Properties of plasma coatings from clad titanium carbide powders, Poroshk. Metall., 1993, no. 4, pp. 49–52.

Fouvry, S., Wendler, B., Liskiewicz, T., Dudek, M., and Kolodziejczyk, L., Fretting wear analysis of TiC/VC multilayered hard coatings: Experiments and modeling approaches, Wear, 2004, vol. 257, nos. 7–8, pp. 641–653.

Tkachenko, Yu.G., Yurchenko, D.Z., Britun, V.F., Isaeva, L.P., and Varchenko, V.T., Structure and properties of wear-resistant electrospark coatings when using titanium carbide hard alloys as anode, Poroshk. Metall., 2013, nos. 5/6, pp. 86–96.

Isalgue, A., Fernandez, J., Cinca, N., Villa, M., and Guilemany, J.M., Mechanical and nanoindentation behavior of TiC–TiNi thermal spray coating, J. Alloys Compd., 2013, vol. 577, pp. 5277–5281. https://doi.org/10.1016/j.jallcom.2012.05.033

Gnyusov, S.F. and Tarasov, S.Yu., The microstructural aspects of abrasive wear resistance in composite electron beam clad coatings, Appl. Surf. Sci., 2014, vol. 293, pp. 318–325. https://doi.org/10.1016/j.apsusc.2013.12.161

Adamovskii, A.A., Transition metal carbides in abrasive processing, Poroshk. Metall., 2007, nos. 11/12, pp. 96–111.

Merzhanov, A.G., Karyuk, G.G., Borovinskaya, I.P., Sharivker, S.Yu., Moshkovskii, E.I., Prokudina, V.K., and Dyad’ko, E.G., Titanium carbide obtained by self-propagating high-temperature synthesis as highly efficient abrasive material, Poroshk. Metall., 1981, no. 10, pp. 50–55.

Zou, B., Huang, C., Song, J., Liu, Z., Liu, L., and Zhao, Y., Mechanical properties and microstructure of TiB2–TiC composite ceramic cutting tool material, Int. J. Refract. Met. Hard Mater., 2012, vol. 35, pp. 1–9. https://doi.org/10.1016/j.ijrmhm.2012.02.011

Zou, B., Ji, W., Huang, C., Wang, J., Li, S., and Xu, K., Effects of superfine refractory carbide additives on microstructure and mechanical properties of TiB2–TiC + Al2O3 composite ceramic cutting tool materials, J. Alloys Compd., 2014, vol. 585, pp. 192–202. https://doi.org/10.1016/j.jallcom.2013.09.119

Kharlamov, A.I. and Kirillova, N.V., Catalytic properties of powders of transition elements refractory compounds. Carbides and nitrides, Poroshk. Metall., 1983, no. 2, pp. 55–67.

Rodriguez, J.A., Evans, J., Feria, L., Vidal, A.B., Liu, P., Nakamura, K., and Illas, F., CO2 hydrogenation on Au/TiC, Cu/TiC, and Ni/TiC catalysts: Production of CO, methanol, and methane, J. Catal., 2013, vol. 307, pp. 162–169. https://doi.org/10.1016/j.jcat.2013.07.023

Wu, X.Y., Li, G.Z., Chen, Y.H., and Li, G.Y., Microstructure and mechanical properties of vanadium carbide coatings synthesized by reactive magnetron sputtering, Int. J. Refract. Met. Hard Mater., 2009, vol. 27, no. 3, pp. 611–614. https://doi.org/10.1016/j.ijrmhm.2008.09.014

Quanlin, W., Wenge, L., Ning, Z., Gang, W., and Haishan, W., Microstructure and wear behavior of laser cladding VC–Cr7C3 ceramic coating on steel substrate, Mater. Des., 2013, vol. 49, pp. 10–18. https://doi.org/10.1016/j.matdes.2013.01.067

Kurlov, A.S. and Gusev, A.I., Fizika i khimiya karbidov vol’frama (Physics and Chemistry of Tungsten Carbides), Moscow: Fizmatlit, 2013.

Soleimanpour, A.M., Abachi, P., and Simchi, A., Microstructure and mechanical properties of WC–10Co cemented carbide containing VC or (Ta,Nb)C and fracture toughness evaluation using different models, Int. J. Refract. Met. Hard Mater., 2012, vol. 31, pp. 141–146. https://doi.org/10.1016/j.ijrmhm.2011.10.004

Lin, G.G., Kny, E., Yuan, G., and Djuricic, B., Microstructure and properties of ultrafine WC–0.6VC–10Co hardmetals densified by pressure-assisted critical liquid phase sintering, J. Alloys Compd., 2004, vol. 383, nos. 1–2, pp. 98–102. https://doi.org/10.1016/j.jallcom.2004.04.070

Wang, H., Fang, Z.Z., and Sohn, H.Y., Grain growth during the early stage of sintering of nanosized WC-Co powder, Int. J. Refract. Met. Hard Mater., 2008, vol. 26, no. 3, pp. 232–241. https://doi.org/10.1016/j.ijrmhm.2007.04.006

Xiao, D., He, Y., Luo, W., and Song, M., Effect of VC and NbC additions on microstructure and properties of ultrafine WC–10Co cemented carbides, Trans. Nonferrous Met. Soc. China, 2009, vol. 19, no. 6, pp. 1520–1525. https://doi.org/10.1016/S1003-6326(09)60063-7

Bonache, V., Salvador, M.D., Fernandez, A., and Borrell, A., Fabrication of full density near-nanostructured cemented carbides by combination of VC/Cr3C2 addition and consolidation by SPS and HIP technologies, Int. J. Refract. Met. Hard Mater. 2011, vol. 29, no. 2, pp. 202–208. https://doi.org/10.1016/j.ijrmhm.2010.10.007

Bonache, V., Salvador, M.D., Rocha, V.G., and Borrell, A., Microstructural control of ultrafine and nanocrystalline WC–12Co–VC/Cr3C2 mixture by spark plasma sintering, Ceram. Int., 2011, vol. 37, no. 3, pp. 1139–1142. https://doi.org/10.1016/j.ceramint.2010.11.026

Sun, L., Tian’en, Y., Jia, C., and Hiong, J., VC, Cr3C2 doped ultrafine WC–Co cemented carbides prepared by spark plasma sintering, Int. J. Refract. Met. Hard Mater., 2011, vol. 29, no. 2, pp. 147–152. https://doi.org/10.1016/j.ijrmhm.2010.09.004

Mahmoodan, M., Aliakbarzadeh, H., and Gholamipour, R., Sintering of WC–10%Co nano powders containing TaC and VC grain growth inhibitors, Trans. Nonferrous Met. Soc. China, 2011, vol. 21, no. 5, pp. 1080–1084. https://doi.org/10.1016/S1003-6326(11)60825-X

Zhao, Z., Microwave-assisted synthesis of vanadium and chromium carbides nanocomposite and its effect on properties of WC–8Co cemented carbides, Scr. Mater., 2016, vol. 120, pp. 103–106. https://doi.org/10.1016/j.scriptamat.2016.04.024

Chen, H., Yang, Q., Wang, J., Yang, H., Chen, L., Ruan, J., and Huang, Q., Effects of VC/Cr3C2 on WC grain morphologies and mechanical properties of WC–6 wt % Co cemented carbides, J. Alloys Compd., 2017, vol. 714, pp. 245–250. https://doi.org/10.1016/j.jallcom.2017.04.187

Espinoza-Fernández, L., Borrell, A., Salvador, M.D., and Gutierrez-Gonzalez, C.F., Sliding wear behavior of WC–Co–Cr3C2–VC composites fabricated by conventional and nonconventional techniques, Wear, 2013, vol. 307, nos. 1–2, pp. 60–67. https://doi.org/10.1016/j.wear.2013.08.003

Li, Y., Zheng, D., Li, X., Qu, S., and Yang, C., Cr3C2 and VC doped WC–Si3N4 composites prepared by spark plasma sintering, Int. J. Refract. Met. Hard Mater., 2013, vol. 41, pp. 540–546. https://doi.org/10.1016/j.ijrmhm.2013.07.004

Zhan, B., Liu, N., Jin, Z., Li, Q., and Shi, J., Effect of VC/Cr3C2 on microstructure and mechanical properties of Ti(C,N)-based cermets, Trans. Nonferrous Met. Soc. China, 2012, vol. 22, no. 5, pp. 1096–1105. https://doi.org/10.1016/S1003-6326(11)61289-2

Meunier, F., Delporte, P., Heinrich, B., Bouchy, C., Crouzet, C., Pham-Huu, C., Panissod, P., Lerou, J.J., Mills, P.L., and Ledoux, M.J., Synthesis and characterization of high specific surface area vanadium carbide; application to catalytic oxidation, J. Catal., 1997, vol. 169, no. 1, pp. 33–44. https://doi.org/10.1006/jcat.1997.1694

Choi, J.-G., Ammonia decomposition over vanadium carbide catalysts, J. Catal., 1999, vol. 182, no. 1, pp. 104–116. https://doi.org/10.1006/jcat.1998.2346

Rodríguez, P., Brito, J.L., Albornoz, A., Labadí, M., Pfaff, C., Marrero, S., Moronta, D., and Betancourt, P., Comparison of vanadium carbide and nitride catalysts for hydrotreating, Catal. Commun., 2004, vol. 5, no. 2, pp. 79–82. https://doi.org/10.1016/j.catcom.2003.11.011

Gurin, V.N., Methods for the synthesis of refractory compounds and prospects for their application to create new materials, Zh. VKhO Mendeleeva, 1979, vol. 24, no. 3, pp. 212–222.

Merzhanov, A.G. and Borovinskaya, I.P., Self-propagating high-temperature synthesis in the chemistry and technology of refractory compounds, Zh. VKhO Mendeleeva, 1979, vol. 24, no. 3, pp. 223–227.

Svoistva elementov (Properties of Elements), part 1: Fizicheskie svoistva. Spravochnoe izdanie (Physical Properties: Reference Book), Samsonov, G.V., Ed., Moscow: Metallurgiya, 1976.

Samsonov, G.V. and Perminov, V.P., Magnietermiya (Magnesiothermy), Moscow: Metallurgiya, 1971.

Kiffer, R. and Benezovsky, F., Hartmetalle, Vienna: Springer-Verlag, 1965.

Shkiro, V.M. and Borovinskaya, I.P., Investigation of regularities of titanium-carbon mixtures combustion, Protsessy goreniya v khimicheskoi tekhnologii i metallurgii (Combustion Processes in Chemical Technology and Metallurgy), Chernogolovka, Moscow oblast: Ob”edinennyi Inst. Khim. Fiz. Akad. Nauk SSSR, 1975, pp. 253–258.

Prokudina, V.K., Ratnikov, V.I., Maslov, V.M., Borovinskaya, I.P., Merzhanov, A.G., and Dubovitskii, F.I., Technology of titanium carbides, Protsessy goreniya v khimicheskoi tekhnologii i metallurgii (Combustion Processes in Chemical Technology and Metallurgy), Chernogolovka, Moscow oblast: Ob”edinennyi Inst. Khim. Fiz. Akad. Nauk SSSR, 1975, pp. 136–141.

Shkiro, V.M., Borovinskaya, I.P., and Merzhanov, A.G., Study of the reaction properties of various types of carbon in synthesis of titanium carbide by SHS method, Poroshk. Metall., 1979, no. 10, pp. 6–9.

Shkiro, V.M., Prokudina, V.K., and Borovinskaya, I.P., Effect of oxidation of titanium powders on synthesis of titanium carbide by SHS method, Poroshk. Metall., 1981, no. 12, pp. 49–54.

Nersisyan, H.H., Lee, J.H., and Won, C.W., Self-propagating high-temperature synthesis of nano-sized titanium carbide powder, J. Mater. Res., 2002, vol. 17, no. 11, pp. 2859–2864. https://doi.org/10.1557/JMR.2002.0415

Yang, Y.F. and Mu, D.K., Rapid dehydrogenation of TiH2 and its effect on formation mechanism of TiC during self-propagation high-temperature synthesis from TiH2–C system, Powder Technol., 2013, vol. 249, pp. 208–211. https://doi.org/10.1016/j.powtec.2013.08.020

Popovich, A.A., Reva, V.P., Vasilenko, V.N., Popovich, T.A., and Belous, O.A., Mechanochemical method for obtaining powders of refractory compounds (review), Poroshk. Metall., 1993, no. 2, pp. 37–43.

Liu, Z.G., Tsuchiya, K., and Umemoto, M., Mechanical milling of fullerene with carbide forming elements, J. Mater. Sci., 2002, vol. 37, pp. 1229–1235. https://doi.org/10.1023/A:1014383909485

Rahaei, M.B., Yazdani rad, R., Kazemzadeh, A., and Ebadzadeh, T., Mechanochemical synthesis of nano TiC powder by mechanical milling of titanium and graphite powders, Powder Technol., 2012, vol. 217, pp. 369–376. https://doi.org/10.1016/j.powtec.2011.10.050

Onishchenko, D.V. and Reva, V.P., Specificity of mechanochemical synthesis of titanium carbide using various carbon agents, Poroshk. Metall., 2013, nos. 3/4, pp. 63–74.

Abderrazak, H., Schoenstein, S., Abdellaoui, M., and Jouini, N., Spark plasma sintering consolidation of nanostructured TiC prepared by mechanical alloying, Int. J. Refract. Met. Hard Mater., 2011, vol. 29, no. 2, pp. 170–176. https://doi.org/10.1016/j.ijrmhm.2010.10.003

Lyakhov, N., Grigoreva, T., Cepelak, V., Tolochko, B., Ancharov, A., Vosmerikov, S., Devyatkina, E., Udalova, T., and Petrova, S., Rapid mechanochemical synthesis of titanium and hafnium carbides, J. Mater. Sci., 2018, vol. 53, pp. 13584–13591. https://doi.org/10.1007/s10853-018-2450-x

Borovinskaya, I.P., Ignat’eva, T.I., Vershinnikov, V.I., Miloserdova, O.M., and Semenova, V.N., Self-propagating high-temperature synthesis of ultra-and nanodispersed WC and TiC powders, Poroshk. Metall., 2008, nos. 9/10, pp. 3–12.

Ma, J., Wu, M., Du, Y., Chen, S., Li, G., and Hu, J., Synthesis of nanocrystalline titanium carbide with a new convenient route at low temperature and its thermal stability, Mater. Sci. Eng., B, 2008, vol. 153, nos. 1–3, pp. 96–99. https://doi.org/10.1016/j.mseb.2008.10.025

Won, H.I., Nersisyan, H., Won, C.W., and Lee, H.H., Simple synthesis of nano-sized refractory metal carbides by combustion process, J. Mater. Sci., 2011, vol. 46, pp. 6000–6006. https://doi.org/10.1007/s10853-011-5562-0

Ebrahimi-Kahrizsangi, R., Alimardani, M., and Torabi, O., Investigation on mechanochemical behavior of the TiO2–Mg–C system reactive mixtures in the synthesis of titanium carbide, Int. J. Refract. Met. Hard Mater., 2015, vol. 52, pp. 90–97. https://doi.org/10.1016/j.ijrmhm.2015.05.008

Zhou, L., Yang, L., Shao, L., Chen, B., Meng, F., Qian, Y., and Hu, L., General fabrication of boride, carbide and nitride nanocrystals via a metal-hydrolysis-assisted process, Inorg. Chem., 2017, vol. 56, no. 5, pp. 2440–2447. https://doi.org/10.1021/acs.inorgchem.6b02501

Wang, L., Li, Q., Zhu, Y., and Qian, Y., Magnesium-assisted formation of metal carbides and nitrides from metal oxides, Int. J. Refract. Met. Hard Mater., 2012, vol. 31, pp. 288–292. https://doi.org/10.1016/j.ijrmhm.2011.10.009

Aleksandrovskii, S.V., Sizyakov, V.M., Geilikman, M.B., and Gaidamako, I.M., Some characteristics of the production of carbidized titanium by thermal reduction of titanium and carbon chlorides with magnesium, Russ. J. Appl. Chem., 1998, vol. 71, no. 11, pp. 1881–1884.

Dyjak, S., Norek, M., Polanski, M., Cudzilo, S., and Bystrzycki, J., A simple method of synthesis and surface purification of titanium carbide powder, Int. J. Refract. Met. Hard Mater., 2013, vol. 38, pp. 87–91. https://doi.org/10.1016/j.ijrmhm.2013.01.004

Kudaka, K., Iizumi, K., Iizumi, H., and Sasaki, T., Synthesis of titanium carbide and titanium diboride by mechanochemical displacement, J. Mater. Sci. Lett., 2001, vol. 20, pp. 1619–1622. https://doi.org/10.1023/A:1017906012176

Alymov, M.I., Shustov, V.S., Kasimtsev, A.V., Zhigunov, V.V., Ankudinov, A.B., and Zelenskii, V.A., Synthesis of titanium carbide nanopowders and production of porous materials on their basis, Nanotechnol. Russ., 2011, vol. 6, nos. 1–2, pp. 130–136. https://doi.org/10.1134/S1995078011010022

Wang, L., Li, Q., Mei, T., Shi, L., Zhu, Y., and Qian, Y., A thermal reduction route to nanocrystalline transition metal carbides from waste polytetrafluoroethylene and metal oxides, Mater. Chem. Phys., 2012, vol. 137, no. 1, pp. 1–4. https://doi.org/10.1016/j.matchemphys.2012.08.008

Rosin, I.V. and Tomina, L.D., Obshchaya i neorganicheskaya khimiya. Sovremennyi kurs (General and Inorganic Chemistry: Modern Course), Moscow: Yurait, 2012.

Elyutin, V.P., Pavlov, Yu.A., Polyakov, V.P., and Sheboldaev, S.B., Vzaimodeistvie tugoplavkikh oksidov metallov s uglerodom (Interaction of Metal Oxides with Carbon), Moscow: Metallurgiya, 1976.

Vodop’yanov, A.G., Kozhevnikov, G.N., and Baranov, S.V., Interaction of refractory metal oxides with carbon, Russ. Chem. Rev., 1988, vol. 57, no. 9, pp. 810–823. https://doi.org/10.1070/RC1988v057n09ABEH003392

Fiziko-khimicheskie svoistva okislov. Spravochnoe izdanie (Physicochemical Properties of Oxides: Reference Book), Samsonov, G.V., Ed., Moscow: Metallurgiya, 1978.

Lyubimov, V.D., Timoshchuk, T.A., and Kalacheva, M.V., On mechanism of titanium carbide formation during carbothermal reduction of titanium dioxide, Metally, 1992, no. 3, pp. 16–21.

Stolle, S., Gruner, W., Pitschke, W., Berger, L.-M., and Wetzig, K., Comparative microscale investigations of the carbothermal synthesis of (Ti, Zr, Si) carbides with oxide intermediates of different volatilities, Int. J. Refract. Met. Hard Mater., 2000, vol. 18, no. 1, pp. 61–72.

Gruner, W., Stolle, S., and Wetzig, K., Formation of COx species during the carbothermal reduction of oxides of Zr, Si, Ti, Cr, W, and Mo, Int. J. Refract. Met. Hard Mater., 2000, vol. 18, nos. 2–3, pp. 137–145. https://doi.org/10.1016/S0263-4368(00)00013-5

Moiseev, G.K., Popov, S.K., Ovchinnikov, L.A., and Vatolin, N.A., Formation of titanium and zirconium carbides during the interaction of their oxides with carbon in low-temperature plasma, Izv. Akad. Nauk SSSR. Neorg. Mater., 1982, vol. 18, no. 9, pp. 1521–1524.

Eick, B.M. and Youngblood, J.P., Carbothermal reduction of metal-oxide powders by synthetic pitch to carbide and nitride ceramics, J. Mater. Sci., 2009, vol. 44, pp. 1159–1171. https://doi.org/10.1007/s10853-009-3249-6

Kasimuthumaniyan, S., Singh, S.K., Jayasankar, K., Mohanta, K., and Mandal, A., An alternate approach to synthesize TiC powder through thermal plasma processing of titania rich slag, Ceram. Int., 2016, vol. 42, no. 16, pp. 18004–18011. https://doi.org/10.1016/j.ceramint.2016.07.169

Chen, B., Yang, L., Heng, H., Chen, J., Zhang, L., Xu, L., Qian, Y., and Yang, J., Additive-assisted synthesis of boride, carbide and nitride micro/nanocrystals, J. Solid State Chem., 2012, vol. 194, pp. 219–224. https://doi.org/10.1016/j.jssc.2012.05.032

Krutskii, Yu.L., Bannov, A.G., Antonova, E.V., Shinkarev, V.V., Maksimovskii, E.A., Ukhina, A.V., Solov’ev, E.A., Krutskaya, T.M., Razumakov, A.A., Golovin, D.D., and Netskina, O.V., Synthesis of highly dispersed titanium carbide powder using nanofiber carbon, Perspektivnye Mater., 2014, no. 2, pp. 1–6.

Krutskii, Yu.L., Lozhkina, E.A., Maksimovskii, E.A., Balaganskii, I.A., Popov, M.V., Netskina, O.V., Tyurin, A.G., and Kvashina, T.S., The use of nanofibrous carbon to obtain highly dispersed titanium carbide, Nauchn. Vestn. Novosibiskogo Gos. Tekh. Univ., 2017, no. 4, pp. 179–191. https://doi.org/10.17212/1814-1196-2017-4-179-191

Kuvshinov, G.G., Mogilnykh, Yu.L., Kuvshinov, D.G., Yermakov, D.Yu., Yermakova, M.A., Salanov, A.N., and Rudina, N.A., Mechanism of porous filamentous carbon granule formation on catalytic hydrocarbon decomposition, Carbon, 1999, vol. 37, no. 8, pp. 1239–1246. https://doi.org/10.1016/S0008-6223(98)00320-0

Blott, S.J. and Pye, K., Gradistat: A grain size distribution and statistics package for the analysis of unconsolidated sediments, Earth Surf. Processes Landforms, 2001, vol. 26, no. 11, pp. 1237–1248. https://doi.org/10.1002/esp.261

Kazenas, E.K. and Tsvetkov, Yu.V., Termodinamika ispareniya oksidov (Thermodynamics of Oxides Evaporation), Moscow: LKI, 2008.

Preiss, H., Berger, L.-M., and Schultze, D., Studies on the carbothermal preparation of titanium carbide from different gel precursors, J. Eur. Ceram. Soc., 1999, vol. 19, no. 2, pp. 195–206. https://doi.org/10.1016/S0955-2219(98)00190-3

Leconte, Y., Maskrot, H., Combemale, L., Herlin-Boime, N., and Reynaud, C., Application of the laser pyrolysis to the synthesis of SiC, TiC and ZrC pre-ceramics nanopowders, J. Anal. Appl. Pyrolysis, 2007, vol. 79, nos. 1–2, pp. 465–470. https://doi.org/10.1016/j.jaap.2006.11.009

Lin, H., Tao, B., Xiong, J., and Li, Q., Using a cobalt activator to synthesize titanium carbide nanopowders, Int. J. Refract. Met. Hard Mater., 2013, vol. 41, pp. 363–365. https://doi.org/10.1016/j.ijrmhm.2013.05.010

Chen, X., Fan, J., and Lu, Q., Synthesis and characterization of TiC nanopowders via sol-gel and subsequent carbothermal reduction process, J. Solid State Chem., 2018, vol. 262, pp. 44–52. https://doi.org/10.1016/j.jssc.2018.03.006

Ostrovski, O. and Guangqing, Z., Reduction and carburization of metal oxides by methane-containing gas, Am. Inst. Chem. Eng. J., 2006, vol. 52, no. 1, pp. 300–310. https://doi.org/10.1002/aic.10628

Panfilov, S.A., Rezvykh, V.F., Tsvetkov, Yu.V., Kal’kov, A.A., and Khaidarov, V.V., Influence of geometric and consumption parameters on TiC plasma-chemical synthesis during titanium tetrachloride processing, Fiz. Khim. Obrab. Mater., 1979, no. 5, pp. 21–27.

Rezvykh, V.F., Panfilov, S.A., Khaidarov, V.V., and Tsvetkov, Yu.V., Influence of raw material input conditions on titanium carbide synthesis process, Fiz. Khim. Obrab. Mater., 1983, no. 2, pp. 58–61.

Ibragimov, A.T., Kalamazov, R.I., and Tsvetkov, Yu.V., Physicochemical properties of highly dispersed titanium carbide, Fiz. Khim. Obrab. Mater., 1985, no. 5, pp. 84–89.

Saburov, V.P., Cherepanov, A.N., Zhukov, M.F., Galevskii, G.V., Krushenko, G.G., and Borisov, V.T., Plazmokhimicheskii sintez ul’tradispersnykh poroshkov i ikh primenenie dlya modifitsirovaniya metallov i splavov (Plasma-Chemical Synthesis of Ultrafine Powders and Their Application for Modification of Metals and Alloys), Novosibirsk: Nauka, 1995, p. 344.

Amaral, P.M., Fernandes, J.C., Rosa, L.G., Martínez, D., Rodríguez, J., and Shohoji, N., Carbide formation of Va-group metals (V, Nb and Ta) in a solar furnace, Int. J. Refract. Met. Hard Mater., 2000, vol. 18, no. 1, pp. 47–53. https://doi.org/10.1016/S0263-4368(00)00014-7

Zhang, B. and Li, Z.Q., Synthesis of vanadium carbide by mechanical alloying, J. Alloys Compd., 2005, vol. 392, nos. 1–2, pp. 183–186. https://doi.org/10.1016/j.jallcom.2004.09.018

Hassanzadeh-Tabrizi, S.A., Davoodi, D., Beykzadeh, A.A., and Chami, A., Fast synthesis of VC and V2C nanopowders by the mechanochemical combustion method, Int. J. Refract. Met. Hard Mater., 2015, vol. 51, pp. 1–5. https://doi.org/10.1016/j.ijrmhm.2015.02.008

Hossein-Zadeh, M., Razavi, M., Safa, M., Abdollahi, A., and Mirzaee, O., Synthesis and structural evolution of vanadium carbide in nanoscale during mechanical alloying, J. King Saud Univ., Eng. Sci., 2016, vol. 28, no. 2, pp. 207–212. https://doi.org/10.1016/j.jksues.2014.03.010

Ma, J., Wu, M., Du, Y., Chen, S., Ye, J., and Jin, L., Low temperature synthesis of vanadium carbide (VC), Mater. Lett., 2009, vol. 63, no. 11, pp. 905–907. https://doi.org/10.1016/j.matlet.2009.01.033

Chen, Y., Zhang, H., Ye, H., and Ma, J., A simple and novel route to synthesize nano-vanadium carbide using magnesium powders, vanadium pentoxide and different carbon source, Int. J. Refract. Met. Hard Mater., 2011, vol. 29, no. 4, pp. 528–531. https://doi.org/10.1016/j.ijrmhm.2011.03.004

Mahajan, M., Singh, K., and Pandey, O.P., Single step synthesis of nano vanadium carbide, V8C7 phase. International Journal of Refractory Metals and Hard Materials, 2013, vol. 36, pp. 106–110.

Li, C., Yang, X.G., Yang, B.J., and Qian, Y.T., A chemical co-reduction route to synthesize nanocrystalline vanadium carbides, J. Am. Ceram. Soc., 2006, vol. 89, no. 1, pp. 320–322. https://doi.org/10.1111/j.1551-2916.2005.00655.x

Hossein-Zadeh, M. and Mirzaee, O., Synthesis and characterization of V8C7 nanocrystalline powder by heating milled mixture of V2O5, C and Ca via mechanochemical activation, Adv. Powder Technol., 2014, vol. 25, no. 3, pp. 978–982. https://doi.org/10.1016/j.apt.2014.01.017

Shumilova, R.G. and Kosolapova, T.Ya., Semi-industrial production of vanadium carbide, Poroshk. Metall., 1968, no. 11, pp. 83–88.

Zhao, Z., Liu, Y., Cao, H., Gao, S., and Tu, M., Phase evolution during synthesis of vanadium carbide (V8C7) nanopowders by thermal processing of the precursor, Vacuum, 2008, vol. 82, no. 8, pp. 852–855. https://doi.org/10.1016/j.vacuum.2007.12.006

Dai, L.Y., Lin, S.F., Chen, J.F., Zeng, M.Q., and Zhu, M., A new method of synthesizing ultrafine vanadium carbide by dielectric barrier discharge plasma assisted milling, Int. J. Refract. Met. Hard Mater., 2012, vol. 30, no. 1, pp. 48–50. https://doi.org/10.1016/j.ijrmhm.2011.07.002

Krutskii, Yu.L., Tyurin, A.G., Popov, M.V., Maksimovskii, E.A., and Netskina, O.V., Synthesis of fine vanadium-carbide (VC0.88) powder using carbon nanofiber, Steel Transl., 2018, vol. 48, no. 4, pp. 207–213. https://doi.org/10.3103/S096709121804006X

Preiss, H., Schultze, D., and Szulzewsky, K., Carbothermal synthesis of vanadium and chromium carbides from solution-derived precursors, J. Eur. Ceram. Soc., 1999, vol. 19, no. 2, pp. 187–194. https://doi.org/10.1016/S0955-2219(98)00191-5

Lei, M., Zhao, H.Z., Yang, H., Song, B., and Tang, W.H., Synthesis of transition metal carbide nanoparticles through melamine and metal oxides, J. Eur. Ceram. Soc., 2008, vol. 28, no. 8, pp. 1671–1677. https://doi.org/10.1016/j.materresbull.2008.01.016

Li, P.G., Lei, M., and Tang, W.H., Route to transition metal carbide nanoparticles through cyanamide and metal oxides, Mater. Res. Bull., 2008, vol. 43, no. 12, pp. 3621–3626. https://doi.org/10.1016/j.materresbull.2008.01.016

Lei, M., Zhao, H.Z., Yang, H., Song, B., Cao, L.Z., Li, P.G., and Tang, W.H., Syntheses of metal nitrides, metal carbides and rare-earth metal dioxymonocarbodiimides from metal oxides and dicyandiamide, J. Alloys Compd., 2008, vol. 460, nos. 1–2, pp. 130–137. https://doi.org/10.1016/j.jallcom.2007.05.076

Lin, H., Tao, B.W., Li, Q., and Li, Y.R., In situ synthesis of V8C7 nanopowders from a new precursor, Int. J. Refract. Met. Hard Mater., 2012, vol. 31, pp. 138–140. https://doi.org/10.1016/j.ijrmhm.2011.10.003

Liu, F., Yao, Y., Zhang, H., Kang, Y., Yin, G., Huang, Z., Liao, X., and Liang, X., Synthesis and characterization of vanadium carbide nanoparticles by thermal refluxing-derived precursors, J. Mater. Sci., 2011, vol. 46, pp. 3693–3697. https://doi.org/10.1007/s10853-010-5123-y

Isaeva, N.V., Blagoveshchenskii, Yu.V., Blagoveshchenskaya, N.V., Mel’nik, Yu.I., Samokhin, A.V., Alekseev, N.V., and Astashov, A.G., Production of carbide and hard-alloy mixture nanopowders with low-temperature plasma, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkt. Pokrytiya, 2013, no. 3, pp. 7–14. https://doi.org/10.17073/1997-308X-2013-3-7-14

Funding

The work was performed in accordance with the state order of the Ministry of Education and Science (code FSUN-2020-0008).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by F. Baron

About this article

Cite this article

Krutskii, Y.L., Gudyma, T.S., Kuchumova, I.D. et al. Carbides of Transition Metals: Properties, Application and Production. Review. Part 1. Titanium and Vanadium Carbides. Steel Transl. 52, 465–478 (2022). https://doi.org/10.3103/S0967091222050059

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091222050059