Abstract

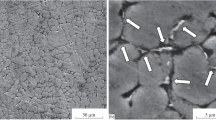

In this paper, we obtain a high-entropy alloy (HEA) of the Al–Co–Cr–Fe–Ni system with a nonequiatomic composition using the technology of wire-arc additive manufacturing (WAAM) in a pure nitrogen atmosphere. Using the methods of modern physical materials science, we showed that the alloy in the initial state has a dendritic structure, which indicates a non-uniform distribution of alloying elements. The alloy is a multiphase material, and the main phases are Al3Ni, Cr3C2, and (Ni,Co)3Al4. Cubic nanosized (Ni,Co)3Al4 particles are located along the interfaces of submicron Al3Ni and Cr3C2 phases. Irradiation of the HEA with pulsed electron beams with an energy density of Es = 10–30 J/cm2, a pulse duration of 50 μs, a frequency of 3 Hz, and a pulse number of 3 leads to high-speed melting and subsequent crystallization of the surface layer. At Es = 10 J/cm2, no destruction of the dendritic crystallization structure occurs. The interdendritic spaces are enriched with aluminum, nickel, and iron while the dendrites themselves are enriched with chromium atoms. The most liquating element is aluminum, and the least liquating element is cobalt. At Es = 20 J/cm2, a nanocrystalline structure is formed in the grain volume in a layer with a thickness of 15 μm. The size of the crystallization cells is 100–200 nm, the size of inclusions are 20–25 nm at the junctions of cells and 10–15 nm along the boundaries of cells. High-speed crystallization cells are enriched with aluminum and nickel. Cobalt atoms are evenly distributed over the volume of the surface layer. The most liquating element is chromium, and the least liquating element is cobalt. An increase in the energy density of the electron beam to 30 J/cm2 does not lead to significant (compared to 20 J/cm2) changes in the structure of the surface layer. The irradiation mode (Es = 20 J/cm2, 50 μs, 3 pulses, 0.3 Hz), which allows to form a surface layer with the highest homogeneity of the chemical element distribution in the alloy, is revealed.

Similar content being viewed by others

REFERENCES

Gromov, V.E., Konovalov, S.V., Ivanov, Yu.F., Osin-tsev, K.A., Rubannikova, Yu.A., Peregudov, O.A., and Semin, A.P., Vysokoentropiinye splavy (High-Entropy Alloys), Novokuznetsk: Poligrafist, 2021.

Zhang, Y., High-Entropy Materials: A Brief Introduction, Singapore: Springer-Verlag, 2019.

Murty, B.S., Yeh, J.-W., Ranganathan, S., and Bhattacharjee, P.P., High-Entropy Alloys, Amsterdam: Elsevier, 2019, 2nd ed.

Rogachev, A.S., Structure, stability, and properties of high-entropy alloys, Phys. Met. Metallogr., 2020, vol. 121, no. 8, pp. 733–764. https://doi.org/10.31857/S0015323020080094

Gromov, V.E., Rubannikova, Yu.A., Konovalov, S.V., Osintsev, K.A., and Vorob’ev, S.V., Generation of increased mechanical properties of Cantor high-entropy alloy, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2021, vol. 64, no. 8, pp. 599–605. https://doi.org/10.17073/0368-0797-2021-8-599-605

Wen, L.H., Kou, H.C., Li, J.S., Chang, H., Xue, X.Y., and Zhou, L., Effect of aging temperature on microstructure and properties of AlCoCrCuFeNi high-entropy alloy, Intermetallics, 2009, vol. 17, no. 4, pp. 266–269. https://doi.org/10.1016/j.intermet.2008.08.012

Ng, C., Guo, S., Luan, J., Shi, S., and Liu, C.T., Entropy-driven phase stability and slow diffusion kinetics in an Al0.5CoCrCuFeNi high entropy alloy, Intermetallics, 2012, vol. 31, pp. 165–172. https://doi.org/10.1016/j.intermet.2012.07.001

Jones, N.G., Frezza, A., and Stone, H.J., Phase equilibria of an Al0.5CrFeCoNiCu high entropy alloy, Mater. Sci. Eng., A, 2014, vol. 615, pp. 214–221. https://doi.org/10.1016/j.msea.2014.07.059

Shun, T.-T. and Du, Y.-C., Age hardening of the Al0.3CoCrFeNiC0.1 high entropy alloy, J. Alloys Compd., 2009, vol. 478, nos. 1–2, pp. 269–272. https://doi.org/10.1016/j.jallcom.2008.12.014

Kao, Y.-F., Chen, T.-J., Chen, S.-K., and Yeh, J.-W., Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys, J. Alloys Compd., 2009, vol. 488, no. 1, pp. 57–64. https://doi.org/10.1016/j.jallcom.2009.08.090

Tsai, C.-W., Chen, Y.-L., Tsai, M.-H., Yeh, J.-W., Shun, T.-T., and Chen, S.-K., Deformation and annealing behaviors of high-entropy alloy Al0.5CoCrCuFeNi, J. Alloys Compd., 2009, vol. 486, nos. 1–2, pp. 427–435. https://doi.org/10.1016/j.jallcom.2009.06.182

Schuh, B., Pippan, R., and Hohenwarter, A., Tailoring bimodal grain size structures in nanocrystalline compositionally complex alloys to improve ductility, Mater. Sci. Eng., A, 2019, vol. 748, pp. 379–385. https://doi.org/10.1016/j.msea.2019.01.073

Xiao, L.L., Zheng, Z.Q., Guo, S.W., Huang, P., and Wang, F., Ultra-strong nanostructured CrMnFeCoNi high entropy alloys, Mater. Des., 2020, vol. 194, art. ID 108895. https://doi.org/10.1016/j.matdes.2020.108895

Li, Z., Gokuldoss Pradeep, K., Deng, Y., Raabe, D., and Tasan, C.C., Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off, Nature, 2016, vol. 534, no. 7606, pp. 227–230. https://doi.org/10.1038/nature17981

Otto, F., Dlouhy, A., Somsen, Ch., Bei, H., Eggeler, G., and George, E.P., The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi highentropy alloy, Acta Mater., 2013, vol. 61, no. 15, pp. 5743–5755. https://doi.org/10.1016/j.actamat.2013.06.018

Coury, F.G., Kaufman, M., and Clarke, A.J., Solid-solution strengthening in refractory high entropy alloys, Acta Mater., 2019, vol. 175, pp. 66–81. https://doi.org/10.1016/j.actamat.2019.06.006

Gludovatz, B., Hohenwarter, A., Catoor, D., Chang, E.H., George, E.P., and Ritchie, R.O., A fracture-resistant high-entropy alloy for cryogenic applications, Science, 2014, vol. 345, no. 6201, pp. 1153–1158. https://doi.org/10.1126/science.1254581

Mills, W.J., Fracture toughness of type 304 and 316 stainless steels and their welds, Int. Mater. Rev., 1997, vol. 42, no. 2, pp. 45–82. https://doi.org/10.1179/imr.1997.42.2.45

Strife, J.R. and Passoja, D.E., The effect of heat treatment on microstructure and cryogenic fracture properties in 5Ni and 9Ni steel, Metall. Trans. A, 1980, vol. 11, no. 8, pp. 1341–1350. https://doi.org/10.1007/BF02653488

Zhang, Y., Zuo, T.T., Tang, Z., Gao, M.C., Dahmen, K.A., Liaw, P.K., and Lu, Z.P., Microstructures and properties of high-entropy alloys, Prog. Mater. Sci., 2014, vol. 61, pp. 1–93. https://doi.org/10.1016/j.pmatsci.2013.10.001

Cantor, B., Multicomponent and high entropy alloys, Entropy, 2014, vol. 16, no. 9, pp. 4749–4768. https://doi.org/10.3390/e16094749

Miracle, D.B. and Senkov, O.N., A critical review of high entropy alloys and related concepts, Acta Mater., 2017, vol. 122, pp. 448–511. https://doi.org/10.1016/j.actamat.2016.08.081

Zhang, W., Lian, P.K., and Zhang, Y., Science and technology in high-entropy alloys, Sci. China Mater., 2018, vol. 61, no. 1, pp. 2–22. https://doi.org/10.1007/s40843-017-9195-8

Gromov, V.E., Aksyonova, K.V., Konovalov, S.V., and Ivanov, Yu.F., Increase of a fatigue life of a silumin by electron-beam processing, Prog. Phys. Met., 2015, vol. 16, no. 4, pp. 265–297. https://doi.org/10.15407/ufm.16.04.265

Koval’, N.N. and Ivanov, Yu.F., Nanostructuring of surfaces of metalloceramic and ceramic materials by electron-beams, Russ. Phys. J., 2008, vol. 51, no. 5, pp. 505–516.

Rotshtein, V.P., Proskurovskii, D.I., Ozur, G.E., and Ivanov, Yu.F., Modifikatsiya poverkhnostnykh sloev metallicheskikh materialov nizkoenergeticheskimi sil’notochnymi elektronnymi puchkami (Modification of Surface Layers of Metallic Materials by Low-Energy High-Current Electron Beams), Novosibirsk: Nauka, 2019.

Shulov, V.A., Paikin, A.G., Novikov, A.S., et al., Sil’notochnye elektronnye impul’snye puchki dlya avia-tsionnogo dvigatelestroeniya (High-Current Electronic Pulse Beams for Aircraft Engine Design), Shulov, V.A., Novikov, A.S., and Engel’ko, V.I., Eds., Moscow: Artek, 2012.

Egerton, F.R., Physical Principles of Electron Microscopy, Basel: Springer-Verlag, 2016.

Kumar, C.S.S.R., Transmission Electron Microscopy: Characterization of Nanomaterials, New York: Springer-Verlag, 2014.

Carter, C.B. and Williams, D.B., Transmission Electron Microscopy, Berlin: Springer-Verlag, 2016.

Funding

This work was supported by the Russian Science Foundation, grant no. 20-19-00452.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by A. Ivanov

About this article

Cite this article

Ivanov, Y.F., Gromov, V.E., Konovalov, S.V. et al. Structural Phase Variations in High-Entropy Alloy upon Pulsed Electron Beam Irradiation. Steel Transl. 51, 788–794 (2021). https://doi.org/10.3103/S096709122111005X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709122111005X