Abstract

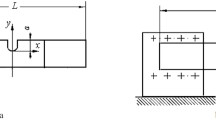

Despite growing interest in the intensification of shape changes by means of current pulses, very limited experimental and theoretical information regarding plastic deformation is available, and the physics of plasticization in metals has not been adequately studied. That is delaying the application of promising techniques in practice. In studying electrically stimulated plastic deformation, it may be useful to regard plastic flow as a wave process. By infrared thermography and double-exposure speckle interferometry, the plastic deformation of low-carbon steel in the presence of pulsed electrical current is studied in the present work. Such treatment increases the velocity of the plasticity waves by 65%. Analysis shows that the velocity distribution corresponds to a impact-transition wave. At first, the velocity of the material is zero (motionless clamp), but on the right side of the graph the velocity of the material is equal to the extension rate specified by the test machine. When current pulses are applied, the distribution of displacement velocities is split at both the mobile and immobile ends of the sample. Thermal data show that a temperature gradient runs from the clamps to the center of the sample. That does not match the distribution of the displacement. In the initial treatment by powerful current pulses, the sample temperature reaches 351 K in the central region of the sample and 330 K at the clamps. In other words, the difference is 21 K. Subsequent treatment increases the temperature only slightly. According to literature data, such increase in temperature decreases the yield point by 10% for the given steel. That corresponds to the results of the present experiments. The present work confirms previous findings regarding the change in velocity of the slow wave on current transmission. The splitting of the velocity values at the mobile clamp has not previously been reported.

Similar content being viewed by others

REFERENCES

Ruszkiewicz, B.J., Grimm, T., Ragai, I., Mears, L., and Roth, J.T., A review of electrically-assisted manufacturing with emphasis on modeling and understanding of the electroplastic effect, J. Manuf. Sci. Eng., 2017, vol. 139, no. 11, pp. 1–15.

Gromov, V.E., Zuev, L.B., Kozlov, E.V., and Tsellermaer, V.Ya., Elektrostimulirovannaya plastichnost’ metallov i splavov (Electrostimulated Plasticity of Metals and Alloys), Moscow: Nauka, 1996.

Jones, J.J. and Mears, L., Constant current density compression behavior of 304 stainless steel and Ti–6Al–4V during electrically-assisted forming, Proc. ASME 2011 Int. Manufacturing Science and Engineering Conf., Corvallis, Oregon, USA, June 13–17, 2011, New York: Am. Soc. Mech. Eng., 2011, no. MSEC2011-50287, pp. 629–637.

Hong, S., Jeong, Y., Chowdhury, M.N., Chun, D., Kim, M., and Han, H.N., Feasibility of electrically assisted progressive forging of aluminum 6061-T6 alloy, CIRP Ann. Manuf. Technol., 2015, vol. 64, no. 1, pp. 277–280.

Tang, G., Zhang, J., Yan, Y., Zhou, H., and Fang, W., The engineering application of the electroplastic effect in the cold-drawing of stainless steel wire, J. Mater. Process. Technol., 2003, vol. 137, no. 1, pp. 96–99.

Sánchez Egea, A.J., González Rojas, H.A., Celentano, D.J., and Peiró, J.J., Mechanical and metallurgical changes on 308L wires drawn by electropulses, Mater. Des., 2016, vol. 90, pp. 1159–1169.

Zhang, D., To, S., Zhu, Y.H., Wang, H., and Tang, G.Y., Static electropulsing-induced microstructural changes and their effect on the ultra-precision machining of cold-rolled AZ91 alloy, Metall. Mater. Trans. A, 2012, vol. 43, no. 4, pp. 1341–1346.

Hameed, S., González Rojas, H.A., Sánchez Egea, A.J., and Napoles Alberro, A., Electroplastic cutting influence on power consumption during drilling process, Int. J. Adv. Manuf. Technol., 2016, vol. 87, nos. 5–8, pp. 1835–1841.

Liu, X., Lan, S., and Ni, J., Electrically assisted friction stir welding for joining Al 6061 to TRIP 780 steel, J. Mater. Process. Technol., 2015, vol. 219, pp. 112–123.

Santos, T.G., Lopes, N., Machado, M., Vilaça, P., and Miranda, R., Surface reinforcement of AA5083-H111 by friction stir processing assisted by electrical current, J. Mater. Process. Technol., 2015, vol. 216, pp. 375–380.

Grasso, S., Sakka, Y., and Maizza, G., Electric current activated/ assisted sintering (ECAS): a review of patents 1906–2008, Sci. Technol. Adv. Mater., 2009, vol. 10, no. 5, p. 053001.

Langer, J. and Hoffmann, M.J., Direct comparison between hot pressing and electric field-assisted sintering of submicron alumina, Acta Mater., 2009, vol. 57, no. 18, pp. 5454–5465.

Xu, D., Lu, B., Cao, T., Zhang, H., Chen, J., Long, H., and Cao, J., Enhancement of process capabilities in electrically-assisted double sided incremental forming, Mater. Des., 2016, vol. 92, pp. 268–280.

Valoppi, B., Sánchez Egea, A.J., Zhang, Z., González Rojas, H.A., Ghiotti, A., Bruschi, S., and Cao, J., A hybrid mixed double-sided incremental forming method for forming Ti6Al4V alloy, CIRP Ann. Manuf. Technol., 2016, vol. 65, no. 1, pp. 309–312.

Xie, H., Dong, X., Peng, F., Wang, Q., Liu, K., Wang, X., and Chen, F., Investigation on the electrically-assisted stress relaxation of AZ31B magnesium alloy sheet, J. Mater. Process. Technol., 2016. vol. 227, pp. 88–95.

Liu, R., Lu, B., Xu, D., Chen, J., Chen, F., Ou, H., and Long, H., Development of novel tools for electricity-assisted incremental sheet forming of titanium alloy, Int. J. Adv. Manuf. Technol., 2016, vol. 85, no. 5, pp. 1137–1144.

Nguyen-Tran, H.-D., Oh, H.-S., Hong, S.-T., Han, H.N., Cao, J., Ahn, S.-H., and Chun, D.-M., A review of electrically-assisted manufacturing, Int. J. Precis. Eng. Manuf. Green Technol., 2015, vol. 2, no. 4, pp. 365–376.

Guan, L., Tang, G., and Chu, P.K., Recent advances and challenges in electroplastic manufacturing processing of metals, J. Mater. Res., 2010, vol. 25, no. 7, pp. 1215–1224.

Zuev, L.B., Gromov, V.E., and Pekker, N.V., Electrostimulation of plasticity wave during the propagation of Lueders lines, Metallofizika, 1992, no. 11, p. 88.

Zuev, L.B., Danilov, V.I., and Barannikova, S.A., Fizika makrolokalizatsii plasticheskogo techeniya (Physics of Macrolocalization of Plastic Flow), Novosibirsk: Nauka, 2008.

Sarychev, V.D. and Petrunin, V.A., Filtration model of plastic deformation, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1993, no. 2, pp. 29–33.

Zel’dovich, Ya.B. and Raizer, Yu.P., Large amplitude shock waves in gases, Usp. Fiz. Nauk, 1957, vol. 63, no. 11, pp. 613–641.

Barannikova, S.A., Kosinov, D.A., Zuev, L.B., Gromov, V.E., and Konovalov, S.V., Influence of hydrogen on the localization of plastic strain in low-carbon steel, Steel Transl., 2016, vol. 46, no. 12, pp. 851–854.

Kuznetsov, V.A., Gromov, V.E., Kuznetsova, E.S., Gagarin, A.Yu., and Kosinov, D.A., Electrostimulated machining of metals, Steel Transl., 2017, vol. 47, no. 2, pp. 113–118.

Zuev, L.B., Gorbatenko, V.V., and Pavlichev, K.V., Elaboration of speckle photography techniques for plastic flow analyses, Meas. Sci. Technol., 2010, vol. 21, no. 5, pp. 054014–054019.

Fedorova, A.Yu., Bannikov, M.V., and Plekhov, O.A., Application of infrared thermography for determination of the linear fracture mechanics parameters, Vestn. Permsk. Nats. Issled. Politekh. Univ., Mekh., 2012, no. 2, pp. 215–225.

Song, P., Li, X., Ding, W., and Chen, J., Electroplastic tensile behavior of 5A90 Al–Li alloys, Acta Metall. Sin. (Engl. Lett.), 2014, vol. 27, no. 4, pp. 642–648.

Kaminskii, P.P., Irreversible deformation of crystals as a structural transformation initiated by change in interatomic interaction, Extended Abstract of Doctoral (Eng.) Dissertation, Tomsk: Inst. Strength Phys. Mater. Sci., Sib. Branch, Russ. Acad. Sci., 2015.

ACKNOWLEDGMENTS

Financial support was provided by the Russian Foundation for Basic Research (grant no. 17-32-50012/17, October 18, 2017; code Stazher) and by the Russian Ministry of Education and Science (project no. 3.1283.2017/4.6).

We thank A. G. Lunev and V. V. Gorbatenko (Institute of Strength Physics and Materials) for assistance in conducting the experiments and interpreting the results.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Gagarin, A.Y., Sarychev, V.D., Nevskii, S.A. et al. Influence of Pulsed Electric Current on the Motion of Spontaneous Plastic-Deformation Waves in Steel-Plate Extension. Steel Transl. 49, 97–101 (2019). https://doi.org/10.3103/S0967091219020062

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219020062