Abstract

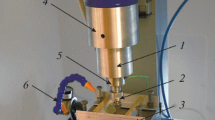

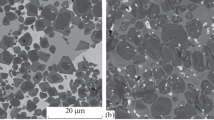

In the present work, a new type of wear-resistant coatings obtained on steels by contactless electro-spark deposition using a rotating electrode and by electrical discharge deposition with a vibrating electrode has been studied. Electrodes have been obtained by pressing and sintering multi-component powder mixtures of hard metal WC-Co with additives of super-hard and refractory compounds of B4C and TiB2 and semi-self-fluxing alloys Ni-Cr-B-Si. High density coatings, with a thickness up to 80 μm and micro hardness up to 17.0 GPa, have been obtained. The roughness, thickness, composition, and structure of the coatings thus obtained have been studied by X-ray diffraction, scanning electron microscopy, and electro-spark deposition. The influence of micro-geometric parameters, composition and structure of coatings on their tribological properties and wear resistance were studied by comparative tests of friction and abrasion wear. The friction tests showed that the wear of the coated steel surfaces is up to 5 times lower compared to the uncoated those. On the base of the experimental data, a comparative analysis of the coatings obtained by the two methods have been made. Appropriate regimes and conditions for deposition of coatings with optimal properties have been defined.

Similar content being viewed by others

REFERENCES

Samsonov, G.V., Verkhoturov, A.D., Bovkun, G.A., and Sychev, V.S., Elektroiskrovoe legirovanie metallicheskikh poverkhnostei (Electrospark Alloying of Metal Surfaces), Kiev: Naukova Dumka, 1976.

Gitlevich, A.E., Mikhailov, V.V., Parkanskii, N.Ya., and Revutskii, V.M., Elektroiskrovoe legirovanie metallicheksikh poverkhnostei (Electrospark Alloying of Metal Surfaces), Chisinau: Shtiintsa, 1985.

Safronov, I.I., Topala, P.A., and Gorbunov, A.S., Elektroerozionnye protsessy na elektrodakh i mikrostrukturno-fazovyi sostav legirovannogo sloya (Electroerosive Processes on Electrodes and Microstructural-Phase Composition of Alloyed Layer), Chisinau: Tekhnika Info, 2009.

Brown, E.A., Sheldon, G.L., and Bayoumi, A.E., Wear, 1990, vol. 138, nos. 1–2, pp. 137–151.

Johnson, R.N. and Sheldon, G.L., J. Vac. Sci. Technol., A, 1986, vol. 4, no. 6, pp. 2740–2746.

Antonov, B., US Patent 3832514, 1974. http://www.google.ch/patents/US3832514.

Antonov, B., Panayotov, S., and Lyutakov, O., US Patent 4 226 697, 1980. http://www.google.ch/patents/ US4226697.

Penyashki, T.G. and Kostadinov, G.D., Agric. Eng., 2013, nos. 4–6, pp. 48–55.

Gadalov, V.N., Romanenko, D.N., Goryakin, I.M., Kamyshnikov, Yu.P., et al., Uprochnyayushchie Tekhnol. Pokrytiya, 2008, no. 4, pp. 33–36.

Bovkun, G.A., Vladkova, Z.I., Molyar, V., Penyashki, T., et al., Sov. Surf. Eng. Appl. Electrochem., 1988, no. 1, pp. 9–12.

Verkhoturov, A.D. and Nikolenko, S.V., Uprochnyayushchie Tekhnol. Pokrytiya, 2010, no. 2, pp. 13–22.

Verkhoturov, A.D., Podchernyaeva, I.A., Pryadko, L.F., and Egorov, F.F., Elektrodnye materially dlya elektroiskrovogo legirovaniya (Electrode Materials for Electrospark Alloying), Moscow: Nauka, 1988.

Nikolenko, V., Verkhoturov, A.D., and Syui, N.A., Surf. Eng. Appl. Electrochem., 2015, vol. 51, no. 1, pp. 38–45.

Kudryashov, A.E., Potanin, A.Yu., Lebedev, D.N., et al., Surf. Coat. Technol., 2016, vol. 285, pp. 278–288.

Penyashki, T., Kostadinov, G., Mortev, I., and Dimitrova, E., Tribol. J. Bultrib, 2016, no. 6, pp. 154–167.

Penyashki, T., Kostadinov, G., Mortev, I., and Dimitrova, E., J. Balkan Tribol. Assoc., 2017, vol. 23, no. 1, pp. 69–81.

Mirkin, L.I., Spravochnik po rentgenostrukturnomu analizu polikristallov (Handbook on X-Ray Analysis of Polycrystals), Moscow: Fizmatlit, 1961.

Penyashki, T.G., Tribol. J. Bultrib, 2014, no. 4, pp. 159–169.

Khromov, V.N. and Kuznetsov, V.S., Uprochnyayushchie Tekhnol. Pokrytiya, 2010, no. 12, pp. 18–21.

Funding

The present work is based on research funded from the Bulgarian National Science Fund of the Ministry of Education and Science under the project “Research and Development of New Wear—Resistant Coatings Using Compositional and Nano Materials”.

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Penyashki, T.G., Radev, D.D., Kandeva, M.K. et al. Structural and Tribological Properties of Multicomponent Coatings on 45 and 210Cr12 Steels Obtained by Electrospark Deposition with WC-B4C-TiB2-Ni-Cr-Co-B-Si Electrodes. Surf. Engin. Appl.Electrochem. 55, 638–650 (2019). https://doi.org/10.3103/S1068375519060097

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375519060097