Abstract

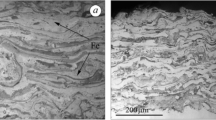

The iron-plating process in methyl sulfate chloride electrolytes was investigated. The conditions of iron plating ensuring the coating adherence with steel and pig iron required in the technological processes of reconditioning and strengthening of machine pieces are determined. Process conditions ensuring the high coating adherence with steels 45, 15HGT, 40H, and grey and high-strength pig iron are found; they include steps: powering on of the polarizing current with the initial density of 0.15–0.5 kA/m2 immediately after insertion of pieces in the electrolyte and raising of the current density up to the working level with a rate of 4–5 A/m2 s. Metallographic, polarizing, and other research show the influence of the initial electrolysis conditions on the formation of the first layers of coverings and the process of iron electrocrystallization on structural phases of tempered steel and grey and high-strength pig iron.

Similar content being viewed by others

References

Alekseev, V.P. and Petrov, Yu.N., Selection of Modes of Surface Preparation in Iron Sulfuric Acid Electrolyte, in Trudy Kishinevskogo SKhI im. M.V.Frunze (Writings of Frunze ACI, Chisinau), Chisinau, 1970, vol. 59, pp. 101–105.

Pankratov, M.P. Issledovanie vliyaniya tekhnologicheskikh faktorov protsessa elektroosazhdeniya zheleza na stseplyaemost’ pokrytii pri vosstanovlenii stal’nykh detalei mashin (Study of Influence of Technological Factors of Iron Electrodeposition Process on Adhesive Capacity of Coatings at Recovery of Steel Machine Pieces), Kharkov: KhADI, 1964.

Andreeva, L.N. and Kalmutskii, V.S., Comparative Studies of Electrolytic Iron Adhesion Strength, Trudy Kishinevskogo SKhI im. M.V. Frunze (Transactions of Frunze ACI, Chisinau), Chisinau, 1970, vol. 59, pp. 45–55.

Melkov, M.P., Tverdoe ostalivanie avtotraktornykh detalei (Hard Steel-Plating of Motor-And-Tractor Pieces), Moscow: Transport, 1971.

Pleshka, E.D., Study and Development of Technology of Recovery of Motor-And-Tractor Pieces by Iron-Plating in Methyl Sulfate Chloride Electrolyte, Cand. Sci. Dissertation, Chisinau, 1979.

Mitryakov, A.V., Obtaining of Strongly Adherent Electrolytic Iron Coatings, in Voprosy teorii i praktiki (Problems of Theory and Practice), Saratov, 1985.

Advancement of Technology for Recovery of Worn-Out Motor-And-Tractor Pieces by Wear Resistant Electrolytic Coatings, in Otchet po NIR 09/11-20 (Report on Research Engineering 09/11-20), Chisinau, 1984, state registration no. 77024435 SRC of Chisinau AGI, Moscow, VNITI no. 02840018082.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.D. Pleshka, 2008, published in Elektronnaya Obrabotka Materialov, 2008, No. 2, pp. 17–24.

About this article

Cite this article

Pleshka, E.D. Adhesion of iron coatings with steel and cast iron. Surf. Engin. Appl.Electrochem. 44, 92–97 (2008). https://doi.org/10.3103/S1068375508020038

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375508020038