Abstract

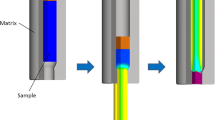

A highly productive method for the cold die forging of blanks makes it possible to fabricate parts with smooth surfaces and the required mechanical characteristics without subsequent heat treatment and machining. The field of application for this method is restricted to high stresses in dies that deform a blank, which reduces their fatigue resistance. Extrusion with applying active friction forces, during which the mold moves in the direction of a blank material flow with a velocity that exceeds the flow velocity, makes it possible to unload dies and produce parts from medium-carbon and low-alloy steels by cold die forging. This work deals with assessing the increase in the fatigue resistance of dies during the extrusion of steel 45 blanks with applying active friction forces.

Similar content being viewed by others

References

Nepershin, R.I., Plastic forming of a wheel gear forge at a crank-type hot forging press, J. Machin. Manufact. Reliab., 2012, vol. 41, pp. 54–63.

Sosenushkin, E.N., Development of plastic deformation systems, Vestnik MGTU “Stankin”, 2010, no. 1, pp. 30–38.

Krasovskii, G.V., Korneev, V.V., and Sosenushkin, E.N., Competitiveness control of projected technological equipment, Kuznechno-Shtampovochnoe Proizvodstvo. Obrabotka Materialov Davleniem, 2010, no. 6, pp. 17–21.

Sosenushkin, E.N., Ovechkin, L.M., and Sosenushkin, A.E., Enhancement of intensive plastic deformation processes, Vestnik MGTU “Stankin”, 2012, no. 1, pp. 21–29.

Ponomarev, A.S., Sosenushkin, E.N., Artes, A.E., and Klimov, V.N., Effect of treatment by pressure on micro-structure and quality of objects from high-strength cast iron, Vestnik MGTU “Stankin”, 2011, no. 3, pp. 115–120.

Artes, A.E. and Sosenushkin, E.N., Problems of large forging production in native machine engineering. Spravochnik. Inzhenernyi Zhurnal s Prilozheniem, 2012, no. 9, pp. 45–50.

Grigor’ev, S.N., Solution of machine engineering technological reequipment problems, Vestnik MGTU “Stankin”, 2008, no. 3, pp. 5–9.

Kovka i shtampovka: Spravochnik. V 4-kh t. T. 3. Kholodnaya ob”emnaya shtampovka. Shtampovka metallicheskikh poroshkov (Forging and Punching: Handbook. In 4 vols., Vol. 3. Cold Volume Punching. Punching of Metallic Powders), Dmitriev, A.M. and Semenov, E.I., Eds., Moscow: Mashinostroenie, 2010, 2nd ed.

Grigor’ev, S.N., Problems and perspectives of development of native machine engineering manufacture, Spravochnik. Inzhenernyi Zhurnal s Prilozheniem, 2011, no. 12, pp. 3–7.

Ponomarev, A.S., Sosenushkin, E.N., and Klimov, V.N., Effect of process features of pressure treatment on the microstructure and quality of parts of pipeline fittings from high-strength cast iron, Metal Sci. Heat Treat., 2012, vol. 54, pp. 22–27.

Grigor’ev, S.N., Dmitriev, A.M., and Korobova, N.V., Mechanical characteristics of construction carbon steels at cold volume punching and their description by approximating dependences, Spravochnik. Inzhenernyi Zhurnal s Prilozheniem, 2011, no. 12, pp. 23–26.

Demin, V.A., Dmitriev, A.M., Subich, V.N., and Shestakov, N.A., Science-intensive technologies at blank production by pressure treatment. Ch. 3, in Suslov, A.G., Bazrov, V.M., Bez”yazychnyi, V.F., et al., Naukoemkie tekhnologii v mashinostroenii (Science-Intensive Technologies in Machine Engineering), Suslov, A.G., Ed., Moscow: Mashinostroenie, 2012.

Unksov, E.P., Johnson, W., Kolmogorov, V.L., Kudo, H., et al., Teoriya kovki i shtampovki: Ucheb. posobie dlya studentov mashinostroitel’nykh i metallurgicheskikh spetsial’nostei vuzov (Theory of Forging and Punching. A Textbook for Students of Machine Engineering and Metallurgical Specialities of Higher Educational Institutes), Unksov, E.P. and Ovchinnikov, A.G., Eds., Moscow: Mashinostroenie, 1992.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.M. Dmitriev, N.V. Korobova, 2013, published in Trenie i Iznos, 2013, Vol. 34, No. 3, pp. 306–314.

About this article

Cite this article

Dmitriev, A.M., Korobova, N.V. Expanding field of application of cold die forging by inducing active contact friction forces. J. Frict. Wear 34, 232–237 (2013). https://doi.org/10.3103/S1068366613030057

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366613030057