Abstract

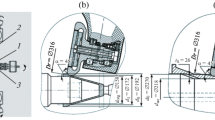

This work is devoted to the specific features of the rolling of hollow shafts made of nickel-base superalloys under conditions of superplasticity. Limitations are mentioned, which hamper the use of the highly efficient multiroller rolling of the shafts made of these alloys under conditions of superplasticity. The tried and tested procedure of rolling hollow shafts, which involves the use of a mandrel and a single roller, is presented. It is shown that the shaping of a shaft using this procedure requires an expanded bulk deformation zone to appear, which propagates over the entire cross section of the blank under the zone of its contact with the roller. The dimensions of the tool that provide the formation of this deformation zone are determined. The possibility of the use of the axisymmetric formulation of the problem on bulk deformation in the course of the rolling of shafts to determine the stress-strain state of the material is substantiated with the help of the Deform-3D applied software package.

Similar content being viewed by others

References

Kaibyshev, O.A. and Utyashev, F.Z., Superplastisity: Microstructurial Refinement and Superplastic Roll Forming, Arlington: Futurepast, 2005.

Utyashev, F.Z., Sukhorukov, R.Yu., Sidorov, A.A., et al., Mathematical simulation for manufacturing aviation axial-symmetric elements by means of local deformation method, Pis’ma Mater., 2015, no. 5 (2), pp. 175–178.

Kachanov, L.M., Osnovy teorii plastichnosti (Foundations of Plasticity Theory), Moscow: Nauka, 1969.

Utyashev, F.Z., Sukhorukov, R.U., Nazarov, A.A., and Potekaev, A.I., The values of strain components and their role in formation of ultrafine-grained and nanosized structure in materials by means of severe plastic deformation, Russ. Phys. J., 2015, no. 1, pp. 64–71.

Mulyukov, R.R., Nazarov, A.A., Sukhorukov, R.Yu., and Utyashev, Ph.Z., Technological features of a process and equipment for superplastic rolling of axially symmetric heat-resistant steel components of rotors for modern aviation motors, J. Mach. Manuf. Reliab., 2014, vol. 43, no. 4, pp. 311–318.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © F.Z. Utyashev, R.Yu. Sukhorukov, G.V. Samarukov, M.I. Nagimov, 2016, published in Problemy Mashinostroeniya i Nadezhnosti Mashin, 2016, No. 1, pp. 74–80.

About this article

Cite this article

Utyashev, F.Z., Sukhorukov, R.Y., Samarukov, G.V. et al. Specific features of rolling of shaft of gas turbine engine under conditions of superplasticity. J. Mach. Manuf. Reliab. 45, 65–71 (2016). https://doi.org/10.3103/S105261881601012X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S105261881601012X