Abstract

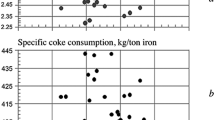

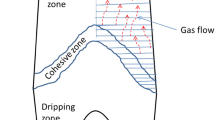

One of the main methods to intensify blast-furnace smelting is to improve the quality of the sintered raw materials. The article presents the study results of the influence of the composition and metallurgical properties of various Mikhailovsky GOK pellets introduced into the blast-furnace charge based on the technical and economic indicators of the blast-furnace treatment. The studies include physical modeling of pellet production of various composition, experimental determination of their metallurgical properties, as well as blast-furnace smelting simulation using the balance logical-and-statistical model of the Institute of Metallurgy, Ural Branch of the Russian Academy of Sciences (IMet). According to the simulation results, the productivity of the blast-furnace process increases when using all the test pellets, and the specific coke consumption decreases. It is revealed that when using iron-rich pellets in the charge, the sulfur concentration in the slag is significantly higher, which creates the risk of producing substandard cast iron. Based on the obtained data analysis, the technology for the use of enriched pellets (SiO2 at the level of 6%) seems to be optimal, as it provides an increase in productivity with a relatively low coke consumption and acceptable slag sulfur content.

Similar content being viewed by others

REFERENCES

Prikaz Ministerstva promyshlennosti i torgovli RF ot 5 maya 2014 g. no. 839 “Ob utverzhdenii Strategii razvitiya chernoi metallurgii Rossii na 2014–2020 gody i na perspektivu do 2030 i Strategii razvitiya tsvetnoi metallurgii Rossii na 2014–2020 gody i na perspektivu do 2030 (Order of the Ministry of Industry and Trade of the Russian Federation No. 839 of May 5, 2014 “On Approval of the Strategic Development of Ferrous Metallurgy in Russia for 2014–2020 and until 2030 and the Strategy of the Strategic Development of Non-Ferrous Metallurgy in Russia for 2014–2020 and until 2030), Moscow, 2014.

Budanov, I.A., New conditions for development of Russian market of metals, Stal’, 2018, no. 8, pp. 64–72.

Zinov’eva, N.G., Export and import of Russian steel products in 2017–2018, Chern. Metall., Byull. Nauchno-Tekh.Ekon. Inf., 2019, vol. 75, no. 8, pp. 903–911.

Geerdes, M., Chaigneau, R., Kurunov, I., Lingiardi, O., and Ricketts, J., Modern Blast Furnace Ironmaking, Amsterdam: IOS Press, 2015.

Kozub, A.V., Panchenko, A.I., Efendiev, N.T., et al., Control of metallurgical properties of iron ore pellets as the general strategy to increase the efficiency of blast furnace production, Trudy VIII Mezhdunarodnogo kongressa domenshchikov “Metallurgiya chuguna-vyzovy XXI veka” (Proc. VIII Int. Congr. of Blast Furnace Workers “Cast Iron Metallurgy as a Challenge of 21st Century”), Moscow: Kodeks, 2017, pp. 508–516.

Yaroshenko, Yu.G., Gordon, Ya.M., and Khodorovskaya, I.Yu., Energoeffektivnye i resursosberegayushchie tekhnologii chernoi metallurgii: uchebnoe posobie (Energy Efficient and Resource Saving Technologies in Ferrous Metallurgy: Manual), Yaroshenko, Yu.G., Ed., Yekaterinburg: Ural. Izd. Poligraf. Tsentr, 2012.

Spravochnik nailuchshikh dostupnykh tekhnologii v promyshlennosti po pererabotke chernykh metallov (Handbook of the Best Available Industrial Technologies for Processing of Ferrous Metals), Moscow: Delovye Lyudi, 2013.

Vinogradov, E.N., Kal’ko, A.A., Volkov, E.A., et al., Specific blast furnace technology with low slag yield, Trudy VIII Mezhdunarodnogo kongressa domenshchikov “Metallurgiya chuguna-vyzovy XXI veka” (Proc. VIII Int. Congr. of Blast Furnace Workers “Cast Iron Metallurgy as a Challenge of 21st Century”), Moscow: Kodeks, 2017, pp. 51–58.

Anisimov, N.K., Naftal’, M.N., Maslov, E.V., et al., Modernization of the industry of Ural Steel Works as a part of strategic development of Metalloinvest Holding, Metallurg, 2016, no. 7, pp. 4–6.

Kretov, S.I., Kozub, A.V., Pigarev, S.P., et al., Roasting machine for client-oriented pellet production, Steel Transl., 2017, vol. 47, no. 12, pp. 814–819.

Chentsov, A.V., Chesnokov, Yu.A., and Shavrin, S.V., Balansovaya logiko-statisticheskaya model’ domennogo protsessa (Balanced Logical-Statistic Model of Blast Furnace Process), Moscow: Nauka, 1991.

Bersenev, I.S., Bersenev, E.S., Bragin, V.V., et al., The effect of basicity and content of magnesium oxide on the quality of iron quartzite pellets, Trudy nauchno-prakticheskoi konferentsii s mezhdunarodnym uchastiem i elementami shkoly molodykh uchenykh “Perspektivy razvitiya metallurgii i mashinostroeniya s ispol’zovaniem zavershennykh fundamental’nykh issledovanii i NIOKR: Ferrosplavy” (Proc. Sci.-Pract. Conf. with Int. Participation and the Elements of School of young Scientists “Prospective Development of Metallurgy and Mchine Engineering Using Completed Fundamental Studies and R&D: Ferroalloys”), Yekaterinburg: Ural’skii Rabochii, 2018, pp. 168–172.

Timofeeva, A.S., Nikitchenko, T.V., and Kozhukhov, A.A., The role of magnesium oxide in the physicochemical and metallurgical properties of iron pellets, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2018, no. 5, pp. 23–28.

Bersenev, I.S. and Starostin, A.N., Analysis of the mineral composition of pellets using decision tree methods and k-means, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2019, no. 7, pp. 796–802.

Bragin, V.V., Bersenev, I.S., Pokolenko, A.Yu., et al., The strength of calcined iron pellets of Mikhailovsky GOK during their fluxing with dolomite, Materialy VIII Vserossiiskoi nauchno-prakticheskoi konferentsii studentov, aspirantov i molodykh uchenykh s mezhdunarodnym uchastiem (TIM’2019) “Teplotekhnika i informatika v obrazovanii, nauke i proizvodstve,” Ekaterinburg, 16–17 maya 2019 g. (Proc. VIII All-Russ. Sci.-Pract. Conf. of Students, Post-Graduate Students, and Young Scientists with Int. Participation (TIM’2019) “Thermal Engineering and Informatics in Education, Science, and Industry,” Yekaterinburg, May 16–17, 2019), Yekaterinburg: Ural. Fed. Univ., 2019, pp. 24–31.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Kolemesin

About this article

Cite this article

Bersenev, I.S., Bragin, V.V., Ugarov, A.A. et al. Improvement of Technical and Economic Performance of Blast-Furnace Smelting by Pellet Composition Optimization. Steel Transl. 50, 171–178 (2020). https://doi.org/10.3103/S0967091220030031

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220030031