Abstract

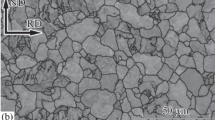

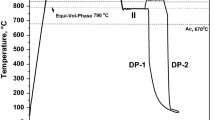

Orientation microscopy (electron back scatter diffraction, EBSD) is used to investigate the structural and textural states of low-carbon, low-alloy pipe steel (resembling 06Г2MБ steel) after thermomechanical controlled processing (TMCP): heating to 1000°C with subsequent quenching in water; isothermal quenching with holding at 300°C; and slow cooling in the furnace. The heat treatment is associated with double phase recrystallization: α → γ → aht, where aht is martensite, bainite, or ferrite. The texture obtained after TMCP is mainly formed by two strong scattered orientations from {112}〈110〉and two weaker scattered orientations close to {110}〈223〉. Despite the double phase recrystallization, the main crystallographic orientations of the bainite after TMCP and after isothermal quenching are the same. That indicates structural and textural inheritance in the material. The structures obtained after other thermal treatments of the structure (both martensite and ferrite) also include complex multicomponent textures, which are nevertheless distinct. Some of the main textural components of martensite and ferrite are the same as bainitic components. All the structures after heat treatment have a similar spectrum of large-angle boundaries, with strongly expressed boundaries of the coincidence site lattices (CSL): Σ3, Σ11, Σ25b, Σ33c, and Σ41c. The orientations forming the texture of all the structures obtained are related to the main orientation of the deformed austenite grains formed on hot rolling in TMCP, in accordance with orientation relations intermediate between the Kurdjumov–Sachs and Nishiyama–Wasserman types. In all cases, the orientation relationship of the textural components of the initial material and the structure obtained by heat treatment may be explained in terms of the onset of phase transformations (both shear and diffusional transition) at crystallographically determined boundaries (including special boundaries) similar to the CSL boundaries Σ3 and Σ11.

Similar content being viewed by others

References

Endo, S. and Nakata, N., Development of Thermo-Mechanical Control Process (TMCP) and high performance steel in JFE Steel, in JFE Technical Report No. 20, Tokyo: JFE Steel Corporation, 2015, pp. 1–7.

Zhao, M.-Sh., Yang, K., and Shan, Y., The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel, Mater. Sci. Eng., A, 2002, vol. 335, pp. 14–20.

Liang, X.J., Hua, M.J., Garcia, C.I., and DeArdo, A.J., The thermomechanical controlled processing of highstrength steel plate: a new view of toughness based on modern metallography, Mater. Sci. Forum, 2013, vol. 762, pp. 38–46.

Nastich, S.Yu., Morozov, Yu.D., Matrosov, M.Yu., Denisov, S.V., Galkin, V.V., and Stekanov, P.A., Assimilation of production in an MMK 5000 mill of thick rolled sheet from low-alloy steels with improved strength and cold resistance properties, Metallurgist, 2012, vol. 55, nos. 11–12, pp. 810–818.

Morozov, Yu.D., Goli-Oglu, E.A., Nastich, S.Yu., Denisov, S.V., and Stekanov, P.A., Thermomechanical treatment of microalloyed low-carbon steel at a 5000 mill for the production of cold-resistant thick strip, Steel Transl., 2012, vol. 42, no. 2, pp. 171–176.

Il’inskii, V.I., Stepanov, P.P., Efron, L.I., Golovin, S.V., Geier, V.V., Matrosov, M.Y., Goli-Oglu, E.A., and Talanov, O.P., Experience of mastering plate production of strength category sawl 450 for deep-water pipes at the Vyksa Metallurgical Plant 5000 mill, Metallurgist, 2014, vol. 58, no. 1, pp. 38–42.

Morozov, Yu.D., Nastich, S.Yu., Matrosov, M.Yu., and Chevskaya, O.N., Obtaining high-quality properties of rolled material for large-diameter pipes based on formation of ferrite-bainite-diameter pipes based on formation of ferrite-bainite microstructure, Metallurgist, 2008, vol. 52, nos. 1–2, pp. 21–28.

Morozov, Yu.D., Matrosov, M.Yu., Nastich, S.Yu., and Arabei, A.B., New generation of high-strength tube steels with a ferrite-bainite structure, Metallurgist, 2008, vol. 52, no. 7–8. pp. 450–456.

Matrosov, M.Yu., Efron, L.I., Kichkina, A.A., and Lyasotskii, I.V., A study of the microstructure of niobium-microalloyed pipe steel after different modes of controlled rolling with accelerated cooling, Met. Sci. Heat Treat., 2008, vol. 50, nos. 3–4. pp. 136–141.

Arabei, A.B., Pyshmintsev, I.Y., Shtremel’, M.A., Glebov, A.G., Struin, A.O., and Gervas’ev, A.M., Resistance of X80 steel to ductile-crack propagation in major gas lines, Steel Transl., 2009, vol. 39, no. 9, pp. 719–724.

Efron, L.I., Morozov, Yu.D., and Goli-Oglu, E.A., Influence of controlled rolling on the structure and mechanical properties of low-carbon microalloy steel, Steel Transl., 2011, vol. 41, no. 5, pp. 434–439.

Hulka, K., Peters, P., and Haisterkamp, F., Trends in the development of large-diameter pipe steels, Steel Transl., 1997, vol. 27, no. 10, pp. 64–70.

Stolheim, D.J., Modern alloy designs and production practice for today’s high strength oil and gas transmission line pipe steels. Part I, Metallurg, 2013, no. 11, pp. 53–66.

Sabirov, I., De Diego-Calderón, I., Molina-Aldareguia, J.M., Föjer, C., Thiessen, R., and Petrov, R.H., Microstructural design in quenched and partitioned (Q&P) steels to improve their fracture properties, Mater. Sci. Eng., A, 2016, vol. 657, pp. 136–146.

Chastukhin, A.V., Ringinen, D.A., Khadeev, G.E., and Efron, L.I., Kinetics of the static recrystallization of austenite of niobium-microalloyed pipe steels, Metallurgist, 2016, vol. 59, no. 11, pp. 1180–1187.

Kichkina, A.A., Matrosov, M.Yu., Efron, L.I., Klyukvin, M.B., and Golovanov, A.V., Effect of structural of anisotropy of ferrite-bainite pipe steel on mechanical properties in tensile and impact bending tests, Metallurgist, 2011, vol. 54, nos. 11–12, pp. 808–816.

Shtremel’, M.A., Prochnost’ splavov. Chast’2. Deformatsiya (Strength of Alloys, Part 2: Deformation), Moscow: Mosk. Inst. Stali Splavov, 1997.

Belyaevskikh, A.S., Lobanov, M.L., Rusakov, G.M., and Redikul’tsev, A.A., Improving the production of superthin anisotropic electrical steel, Steel Transl., 2015, vol. 45, no. 12, pp. 982–986.

Pyshmintsev, I.Yu., Struin, A.O., Gervas’ev, A.M., Lobanov, M.L., Rusakov, G.M., Danilov, S.V., and Arabey, A.B., Effect of bainite crystallographic texture on failure of pipe steel sheets made by controlled thermomechanical treatment, Metallurgist, 2016, vol. 60, no. 3–4, pp. 405–412.

Pyshmintsev, I.Yu., Gervasyev, A.M., Petrov, R.H., et al., Crystallographic texture as a factor enabling ductile fracture arrest in high strength pipeline steel, Mater. Sci. Forum, 2012, vols. 702–703, pp. 770–773.

Mohtadi-Bonab, M.A., Eskandari, M., and Szpunar, J.A., Texture, local misorientation, grain boundary and recrystallization fraction in pipeline steels related to hydrogen induced cracking, Mater. Sci. Eng., A, 2014, vol. 620, pp. 97–106.

Danilov, S.V., Struina, E.R., and Borodina, M.D., Splitting of pipe steel produced by TMCP, Steel Transl., 2017, vol. 47, no. 3, pp. 188–189.

Hölscher, M., Raabe, D., and Lücke, K., Relationship between rolling textures and shear textures in f.c.c. and b.c.c. metals, Acta Metall. Mater., 1994, vol. 42, no. 3, pp. 879–886.

Andreev, Yu.G., Zaikova, E.I., and Shtremel’, M.A., Borders and lineage boundary in batch martensite, Phys. Met. Metallogr., 1990, vol. 49, no. 3, pp. 161–167.

Schastlivtsev, V.M., Blindt, L.B., Rodionov, L.P., and Yakovleva, I.D., Structure of martensite packets in engineering steels, Phys. Met. Metallogr., 1988, vol. 66, no. 4, pp. 123–133.

Nesterova, E.V., Rubtsov, A.S., Rybin, V.R., and Zolotorevskii, N.Yu., High angle boundaries, resulting at phase transformations, Poverkhn.: Fiz., Khim., Mekh., 1982, no. 5, pp. 30–35.

Gong, W., Tomota, Y., Paradowska, A.M. et al., Effects of ausforming temperature on bainite transformation, microstructure and variant selection in nanobainite steel, Acta Mater., 2013, vol. 61, pp. 4142–4154.

Schastlivtsev, V.M., The structural and crystallographic features of the lathy martensite of structural steels, Metally, 2001, no. 5, pp. 32–41.

Pereloma, E.V., Al-Harbi, F., and Gazder, A.A., The crystallography of carbide-free bainites in thermomechanically processed low Si transformation-induced plasticity steels, J. Alloys Compd., 2014, vol. 615, pp. 96–110.

Ray, R.K. and Jonas, J.J., Transformation textures in steels, Int. Mater. Rev., 1990, vol. 35, pp. 1–36.

Hutchinson, B., Ryde, L., Lindh, E., and Tagashira, K., Texture in hot rolled austenite and resulting transformation products, Mater. Sci. Eng., A, 1998, vol. 257, no. 1, pp. 9–17.

Lobanov, M.L., Danilov, S.V., Struin, A.O., Borodina, M.D., and Pyshmintsev, I.Yu., Structural and textural heredity at ↔ transformations in low-carbon low-alloy pipe steel, Vestn. Yuzh.-Ural. Gos. Univ., Ser.: Metall., 2016, vol. 16, no. 2, pp. 46–54.

Rusakov, G.M., Lobanov, M.L., Redikul’tsev, A.A., and Belyaevskikh, A.S., Special misorientations and textural heredity in the commercial alloy Fe–3% Si, Phys. Met. Metallogr., 2014, vol. 115, no. 8, pp. 775–785.

Nakada, N., Ito, H., Matsuoka, Y., et al., Deformation-induced martensitic transformation behavior in cold-rolled and cold-drawn type 316 stainless steels, Acta Mater., 2010, vol. 58, pp. 895–903.

Humphreys, F.J. and Hatherly, M., Recrystallization and Related Annealing Phenomena, Oxford: Elsevier, 2004.

Lobanov, M.L., Rusakov, G.M., Redikul’tsev, A.A. Belikov, S.V., Karabanalov, M.S., Struina, E.R., and Gervas’ev, A.M., Research of special boundaries in lath martensite of low-carbon steel by orientation microscopy, Phys. Met. Metallogr., 2016, vol. 117, no. 3, pp. 254–259.

Stepanov, A.I., Ashikhmina, I.N., Sergeeva, K.I., Belikov, S.V., Musikhin, S.A., Karabanalov, M.S., and Al-Katawi, A.A., Structure and properties of low-alloy Cr–Mo–V steel after austenitization in the intercritical temperature range, Steel Transl., 2014, vol. 44, no. 6, pp. 469–473.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.L. Lobanov, M.D. Borodina, S.V. Danilov, I.Yu. Pyshmintsev, A.O. Struin, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2017, No. 11, pp. 910–918.

About this article

Cite this article

Lobanov, M.L., Borodina, M.D., Danilov, S.V. et al. Texture Inheritance on Phase Transition in Low-Carbon, Low-Alloy Pipe Steel after Thermomechanical Controlled Processing. Steel Transl. 47, 710–716 (2017). https://doi.org/10.3103/S0967091217110055

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217110055