Abstract

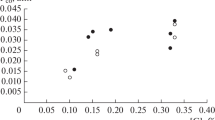

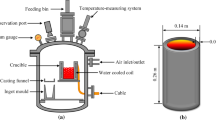

The degassing of 09Г2C steel produced in an arc furnace and treated in a ladle–furnace unit at AO Uralskaya Stal is analyzed. The vacuum-treatment parameters that determine the effectiveness of hydrogen removal from the steel are identified: the depth and duration of vacuum treatment; the argon flow rate; the steel temperature; the thickness of the slag layer; and the free board in the vacuum chamber. The hydrogen content changes most significantly when the degassing time is increased to 20 min. Longer treatment is not recommended. The greatest effect of the residual pressure in degassing is observed with simultaneous decrease in the minimum pressure to 2 mbar. Vacuum treatment of the steel is considerably impaired with increase in the residual pressure. Hydrogen removal is improved with increase in the steel temperature to 1600–1620°C, but slows considerably at higher temperatures. The influence of the vacuum-treatment parameters is established quantitatively, and a regression equation is derived for predicting the results of hydrogen removal and selecting the parameter values corresponding to specified hydrogen content in the steel. Vacuum-treatment parameters that permit the economical production of steel with 2.1 ppm are determined: steel heating before vacuum treatment by 100–110°C; vacuum treatment for 20 min at a pressure no higher than 1.5 mbar in the vacuum chamber; argon flow rate 0.05 m3/t. The temperature losses of the metal are determined by the total treatment time, consisting of the active degassing time and the auxiliary time (the preliminary evacuation time), which depends on the capabilities of the equipment and the organization of the process. The minimum residual hydrogen content in the steel for the given equipment (1.6 ppm) is ensured by vacuum treatment for 40 min at a pressure no higher than 1 mbar in the vacuum chamber, with preliminary heating of the steel by 120–125 °C and with an argon flow rate up to 0.072 m3/t.

Similar content being viewed by others

References

Kudrin, V.A., Teoriya i tekhnologiya proizvodstva stali: Uchebnik dlya vuzov (Theory and Technology of Steel Production), Moscow: Mir, 2003.

Povolotskii, D.Ya., Kudrin, V.A., and Vishkarev, A.F., Vnepechnaya obrabotka stali: uchebnik dlya vuzov (Ladle Treatment of Steel: Manual for Higher Education Institutions), Moscow: Mosk. Inst. Stali Splavov, 1995.

Morozov, A.N., Strekalovskii, M.M., Chernov, G.I., and Katsnel’son, Ya.E., Vnepechnoe vakuumirovanie stali (Ladle Degassing of Steel), Moscow: Metallurgiya, 1975.

Knüppel, H., Desoxydation und Vakuumbehandlung von Stahlschmelzen, Vol. 1: Thermodynamische und Kinetische Grundlagen, Düsseldorf: Stahleisen Verlag, 1970.

Shapovalov, A.N., Tutarova, V.D., and Kalitaev, A.N., Improvement of vacuum degassing technology of axial steels at EAF of Ural Steel Plant, Liteinye Protsessy, 2003, no. 12, pp. 93–103.

Kalitaev, A.N., Tutarova, V.D., Shapovalov, A.N., and Bazhukov, D.O., Problems of formation of quality round billets at CCM, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2013, no. 5, pp. 27–32.

Shevchenko, E.V. and Shapovalov, A.N., Problems of production of quality slab ingot at CCM no. 2 of Ural Steel Plant, Vestn. Yuzh.-Ural. Gos. Univ., Ser. Metall., 2013, vol. 13, no. 1, pp. 68–73.

Tekhnologicheskaya instruktsiya TI13657842-ST. ES-03-2014 Obrabotka stali na ustanovke vakuumirovaniya (Technological Instruction TI13657842-ST. ES-03-2014: Steel Degassing), Novotroitsk: Ural’skaya Stal’, 2014.

Burgmann, W. and Davené, J., The cost structure of vacuum steel degassing including ladle furnace treatment, Stahl Eisen, 2012, vol. 132, no. 6, pp. 59–66.

Zinchenko, S.D., Filatov, M.V., Efimov, S.V., Dub, A.V., and Goshkadera, S.V., Technological aspects of hydrogen removal with the use of a ladle-type vacuum-degassing unit, Metallurgist, 2004, vol. 48, nos. 11–12, pp. 553–556.

Smirnov, A.N. and Safonov, V.M., Steel degassing: technology, equipment, Elektrometallurgiya, 2008, no. 11, pp. 8–14.

Nikolaev, A.O., Bigeev, V.A., Nikolaev, O.A., and Chigasov, D.K., Degassing of pipe steels under the conditions of KKTs OAO MMK, Russ. Metall. (Engl. Transl.), 2013, vol. 2013, no. 12, pp. 901–905.

Zhitlukhin, E.G., Meling, V.V., Dresvyankina, L.E., Gudov, A.G., and Stepanov, I.A., Development and improvement of the efficiency of steel degassing, Stal’, 2014, no. 6, pp. 12–14.

Protasov, A.V., Sivak, B.A., Luk’yanov, A.V., Nikitenko, A.S., and Shchegolev, N.A., Condition and prospects of vacuum ladle of molten steel, Chern. Metall., 2010, no. 11 (1331), pp. 38–44.

Nebosov, Yu.I., Sukharev, S.V., and Kazakov, S.V., Kinetics of hydrogen removal in the gas phase in ladle vacuum treatment, Steel Transl., 2007, vol. 37, no. 7, pp. 572–574.

Ardelean, E., Heput, T., Vatasescu, M., and Crisan, E., Researches regarding the influence of vacuum parameters on the efficiency of gas removal from the liquid steel, Solid State Phenom., 2016, vol. 254, pp. 218–223.

Socalici, A., Popa, E., Heput, T., and Dragoi, F., Researches regarding the improvement of the steel quality, Solid State Phenom., 2014, vol. 216, pp. 273–278.

Yu, S., Miettinen, J., and Louhenkilpi, S., Numerical study on the removal of hydrogen and nitrogen from the melt of medium carbon steel in vacuum tank degasser, Mater. Sci. Forum, 2013, vol. 762, pp. 253–260.

Steneholm, K., Andersson, M., Tilliander, A., and Jönsson, P.G., Removal of hydrogen, nitrogen and sulphur from tool steel during vacuum degassing, Ironmaking Steelmaking, 2013, vol. 40, no. 3, pp. 199–205.

Morozov, A.N., Vodorod i azot v stali (Hydrogen and Nitrogen in Steel), Moscow: Metallurgiya, 1968.

Karpenko, G.V. and Kripyatkevich, R.I., Vliyanie vodoroda na svoistva stali (Effect of Hydrogen on the Properties of Steel), Moscow: Metallurgizdat, 1962.

Fábián, E.R. and Dévényi, L., Hydrogen in the plastic deformed steel, Mater. Sci. Forum, 2007, vols. 537–538, pp. 33–40.

Barannikova, S.A., Lunev, A.G., Nadezhkin, M.V., and Zuev, L.B., Effect of hydrogen on plastic strain localization of construction steels, Adv. Mater. Res., 2014, vol. 880, pp. 42–47.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.D. Tutarova, A.N. Shapovalov, A.N. Kalitaev, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2017, No. 3, pp. 192–199.

About this article

Cite this article

Tutarova, V.D., Shapovalov, A.N. & Kalitaev, A.N. Removal of hydrogen in the vacuum treatment of steel. Steel Transl. 47, 153–158 (2017). https://doi.org/10.3103/S0967091217030159

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217030159