Abstract

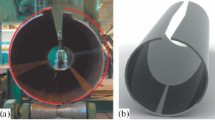

An analytical method is proposed for calculating the shaping parameters of thick sheet in the production of large-diameter pipe. This method is considered in several stages: formulation of a geometric model of the blank and the tool; numerical calculations; selection of the algorithm; and analysis of the results. Comparison of calculated and experimental shaping parameters for sheet used in the production of different types of large-diameter pipe reveals good agreement. The proposed method is recommended for calculating the shaping parameters in the production of large-diameter pipe and the setup so as to minimize the defects due to the geometry of the press.

Similar content being viewed by others

References

Kolikov, A.P., Chern. Met., 2008, no. 11, pp. 8–11.

Efron, L.I., Metallovedenie v bol’shoi metallurgii. Trubnye stali (Physical Metallurgy in Large-Scale Production: Pipe Steel), Moscow: Metallurgizdat, 2012.

Osadchii, V.Ya. and Kolikov, A.P., Proizvodstvo i kachestvo stal’nykh trub (Production and Quality of Steel Pipe), Moscow: MGUPI, 2012.

Dervis, W. and Genzer, B., Trudy XIII Mezhdunar. nauch.-prakt. konf. Truby 2005 (Proceedings of Truby 2005: Thirteenth International Pipe Conference), Chelyabinsk: Rosniti, 2005, vol. 1, pp. 48–49, 105–108.

Pinchuk, A.V. and Kondratov, L.A., Stal’, 2011, no. 5, pp. 51–55.

Shinkin, V.N. and Kolikov, A.P., Stal’, 2011, no. 6, pp. 53–56.

Shinkin, V.N. and Kolikov, A.P., Metallurg, 2011, no. 11, pp. 77–81.

Lifeng, F., Ying, G., Qiang, L., and Xu, H., Chinese J. Mechan. Eng., 2012, vol. 25, no. 6, pp. 1264–1274.

Danchenko, V.N., Milenin, A.A., Kuz’menko, V.I., and Grinkevich, V.A., Komp’yuternoe modelirovanie protsessov obrabotki metallov davleniem. Chislennye metody (Computer Simulation of the Pressure Treatment of Metals: Numerical Methods), Dnepropetrovsk: Sistemnye Tekhnologii, 2005.

Shinkin, V.N., Mekhanika sploshnykh sred (Continuum Mechanics), Moscow: Izd. Dom MISiS, 2010.

Romanovskii, V.P., Spravochnik po kholodnoi shtampovke (Handbook on Cold Stamping), Leningrad: Mashinostroenie, Leningrad. Otd., 1979.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.Ya. Osadchii, E.A. Gaas, D.Yu. Zvonarev, A.P. Kolikov, 2014, published in “Stal’,” 2014, No. 5, pp. 63–66.

About this article

Cite this article

Osadchii, V.Y., Gaas, E.A., Zvonarev, D.Y. et al. Shaping of thick sheet in the production of welded large-diameter pipe. Steel Transl. 44, 374–378 (2014). https://doi.org/10.3103/S0967091214050088

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091214050088