Abstract

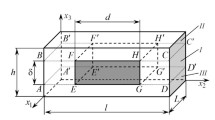

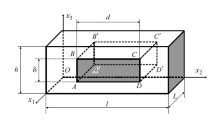

The structural model of hybrid composites angle-ply that were reinforced parallel to some plane is constructed for the analytical determination of the composition’s yield loci while considering the plane stress state in all components. The materials of the components are homogeneous and isotropic, as well as have different yield strengths in tension and compression. Their mechanical behavior is described by the associated flow law for a rigid-plastic body with the piecewise-linear yield conditions of Johansen, Tresca, Hu, and Ishlinsky–Ivlev. The cases of fiber placement along the trajectories of the principal stresses in the composition and the cases of angle-ply reinforcement symmetric with respect to these trajectories are considered. The influence of the reinforcement structure (of directions and densities) on the size and shape of the yield loci of compositions is investigated. It is shown by numerical computations that the plastic flow in the compositions is associated with the calculated yield loci of reinforced media. As an example, yield loci for metal compositions with high-strength and low-strength binder and for fiberglass reinforced media are constructed. The calculated yield loci of the compositions are compared with the ones determined using different variants of the structural model with one-dimensional stress state in fibers.

Similar content being viewed by others

REFERENCES

V. V. Vasiliev and E. Morozov, Advanced Mechanics of Composite Materials and Structural Elements (Elsever, Amsterdam, 2013).

M. F. Caliri, Jr., A. J. M. Ferreira, and V. Tita, “A review on plate and shell theories for laminated and sandwich structures highlighting the finite element method,” Compos. Struct. 156 (15), 63–77 (2016). https://doi.org/10.1016/j.compstruct.2016.02.036

Yu. I. Dimitrienko, Mechanics of Composite Structures at High Temperatures (Fizmatlit, Moscow, 2019) [in Russian].

F. D. Moriniere, R. C. Alderliesten, and R. Benedictus, “Modelling of impact damage and dynamics in fibremetal laminates – a review,” Int. J. Impact. Eng. 67, 27–38 (2014). https://doi.org/10.1016/j.ijimpeng.2014.01.004

N. Jones, “Note on the impact behaviour of fibre-metal laminates,” Int. J. Impact. Eng. 108, 147–152 (2017). https://doi.org/10.1016/j.ijimpeng.2017.04.004

S. K. Gill, M. Gupta, and P. Satsangi, “Prediction of cutting forces in machining of unidirectional glass-fiber-reinforced plastic composites,” Front. Mech. Eng. 8 (2), 187–200 (2013). https://doi.org/10.1007/s11465-013-0262-x

G. I. L’vov and O. A. Kostromitskaya, “Numerical modeling of plastic deformation of unidirectionally reinforced composites,” Mech. Compos. Mater. 56 (1) (2020). https://doi.org/10.1007/s11029-020-09856-8

J. N. Reddy, Mechanics of Laminated Composite Plates and Shells: Theory and Analysis (CRC Press, Boca Raton, 2004).

Yu. S. Solomonov and V. P. Georgievskii, et al., Applied Problems of Mechanics of Composite Cylindrical Shells (Fizmatlit, Moscow, 2014) [in Russian].

J. Zickel, “Isotensoid pressure vessels,” ARS J. 32, 950–951 (1962).

A. Kelly and W. R. Tyson, “Tensile properties of fiber-reinforced metals: copper/tungsten and copper/molybdenum,” J. Mech. Phys. Solids 13 (6), 329–350 (1965). https://doi.org/10.1016/0022-5096(65)90035-9

Yu. V. Nemirovskii, “On the condition of plasticity (strength) for a reinforced layer,” J. Appl. Mech. Techn. Phys. 10 (5), 759–765 (1969). https://doi.org/10.1007/BF00907434

Z. Mróz and F. G. Shamiev, “Simplified yield condition for fiber-reinforced plates and shells,” Arch. Inż. Ląd. 2 (3), 463–476 (1979).

W. Tian, L. Qi, X. Chao, et al., “A new interpolative homogenization model for evaluation of the effective elasto-plastic responses of two-phase composites,” Compos. Struct. 210 (15), 810–821 (2019). https://doi.org/10.1016/j.compstruct.2018.11.075

I. Doghri, L. Adam, and N. Bilger, “Mean-field homogenization of elasto-viscoplastic composites based on a general incrementally affine linearization method,” Int. J. Plast. 26 (2), 219–238 (2010). https://doi.org/10.1016/j.ijplas.2009.06.003

L. Brassart, L. Stainier, I. Doghri, et al., “Homogenization of elasto-(visco) plastic composites based on an incremental variational principle,” Int. J. Plast. 36, 86–112 (2012). https://doi.org/10.1016/j.ijplas.2012.03.010

A. F. Fedotov, “Hybrid model for homogenization of elastoplastic properties of isotropic matrix composites,” Mech. Compos. Mater. 53 (3), 361–372 (2017). doi.org/https://doi.org/10.1007/s11029-017-9667-7

A. P. Yankovskii, “Determination of thermoelastic characteristics of spatially reinforced fibrous media in case of general anisotropy of their components. 1. Structural model,” Mech. Compos. Mater. 46 (5), 663–678 (2010). https://doi.org/10.1007/s11029-010-9162-x

V. M. Akhundov, “Incremental carcass theory of fibrous media under large elastic and plastic deformations,” Mech. Compos. Mater. 51 (3), 539–558 (2015). https://doi.org/10.1007/s11029-015-9509-4

E. Małakhovski, G. L’vov, and S. Daryazadekh, “Numerical prediction of parameters of yield criterion for fibrous composites,” Mech. Compos. Mater. 53 (5), 843–862 (2017). https://doi.org/10.1007/s11029-017-9689-1

T. P. Romanova and A. P. Yankovskii, “Yield loci of reinforced plates made from rigid-plastic unequiresistant materials considering the two-dimensional stress state in fibers. I. Unidirectional reinforcement,” Mech. Compos. Mater. 55 (6), 1019–1042 (2019). https://doi.org/10.1007/s11029-020-09845-x

Handbook of Composites, G. Lubin (Van Nostrand Reinhold, New York, 1982).

R. Hill, Mathematical Theory of Plasticity (Oxford Univ. Press, New York, 1950).

Composite Materials. Handbook, Ed. by D. M. Karpinos (Naukova dumka, Kiev, 1985) [in Russian].

A. R. Rzhanitsyn, Limit Balance of Plates and Shells (Nauka, Moscow, 1983) [in Russian].

Yu. V. Nemirovskii and A. P. Yankovskii, “Limit balance of reinforced concrete domes of rotation,” Izv. Vyssh. Uchebn. Zaved., Stroit., No. 8, 4–11 (2005).

I. N. Kubishev, “Limit load for composite circular plate with various fixation conditions,” Mekh. Mash., Mekh. Mater. 15 (1), 56–60 (2011).

T. P. Romanova, “Carrying capacity and optimization of three-layer reinforced circular plate of differently resistant materials, supported on the internal contour,” Probl. Prochn. Plast. 77 (3), 286–300 (2015). https://doi.org/10.32326/1814-9146-2015-77-3-286-300

A. A. Jakhangirov, “Load-carrying capacity of fiber-reinforced annular tree-layer composite plate clamped on its external and internal contours,” Mech. Compos. Mater. 52 (2), 271–280 (2016). https://doi.org/10.1007/s11029-016-9579-y

T. P. Romanova, “Modeling of rigid-plastic dynamic bending of reinforced layered circular plates with arbitrary hole on viscous foundation under explosive loads,” Probl. Prochn. Plast. 79 (3), 267–284 (2017). https://doi.org/10.32326/1814-9146-2017-79-3-267-284

Yu. N. Rabotnov, Introduction in Destruction Mechanics (Nauka, Moscow, 1987) [in Russian].

I. G. Zhigun, M. I. Dushin, V. A. Polyakov, et al., “Composites reinforced with system of three straight mutually orthogonal fibers. 2. Experimental study,” Polym. Mech. 9 (6), 895–900 (1973). https://doi.org/10.1007/BF00856974

T. P. Romanova and A. P. Yankovskii, “Constructing yield loci for rigid-plastic reinforced plates considering the 2D stress state in fibers,” Mech. Compos. Mater. 54 (6), 697–718 (2018). https://doi.org/10.1007/s11029-019-9777-5

L. W. Hu, “Modified Tresks’s yield condition and associated flow rules for anisotropic materials and applications,” J. Franclin Inst. 265 (3), 187–204 (1958).

G. I. Bykovtsev and D. D. Ivlev, Theory of Plasticity (Dal’nauka, Vladivostok, 1998) [in Russian].

Yu. Mao-hong, “Advances in strength theories for materials under complex stress state in the 20th century,” Appl. Mech. Rev. 55 (3), 169–200 (2002).

V. V. Vasil’ev, V. D. Protasov, V. V. Bolotin, et al., Composite Materials: a Handbook (Mashinostroenie, Moscow, 1990) [in Russian].

T. D. Shermergor, Theory of Elasticity of Microinhomogeneous Media (Nauka, Moscow, 1977) [in Russian].

A. K. Malmeister, V. P. Tamuzh, and G. A. Teters, Resistances of Polymeric and Composite Materials (Zinatne, Riga, 1980) [in Russian].

R. M. Christensen, Mechanics of Composite Materials (Wiley, New York, 1979).

N. S. Bakhvalov and G. P. Panasenko, Averaging of Processes in Periodic Media. Mathematical Problems of Mechanics of Composite Materials (Nauka, Moscow, 1984) [in Russian].

G. A. Vanin, Micromechanics of Composite Materials (Nauk. dumka, Kiev, 1985) [in Russian].

H. G. Hopkins, “Some remarks concerning of the solution of plastic plate problems upon the yield criterion,” in Proc. 9th Int. Congress on Applied Mechanics (Brusseles, 1957), Vol. 6, pp. 448–457.

D. D. Ivlev and L. V. Ershov, Perturbation Methods in Theory of Elastic-Plastic Body (Nauka, Moscow, 1978) [in Russian].

Composites: State of Art, Ed. by L. W. Weeton and E. Scala (AIME, New York, 1974).

D. Kolarov, A. Baltov, and N. Boncheva, Mechanics of Plastic Media (Mir, Moscow, 1979) [in Russian].

Funding

The work was supported by the Program for Fundamental Scientific Research of State Academies of Sciences for 2017–2020, project no. 23.4.1.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by E. Oborin

About this article

Cite this article

Romanova, T.P., Yankovskii, A.P. Piecewise-Linear Yield Loci of Angle-Ply Reinforced Medium of Different-Resisting Rigid-Plastic Materials at 2D Stress State. Mech. Solids 55, 1235–1252 (2020). https://doi.org/10.3103/S0025654420080221

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654420080221