Authors:

Bekele Tesfaye1*, Desalegn Begna2 and Mitiku Eshetu3

1Sinana Agriculture Research Center (SARC), Ethiopia 2Holeta Bee Research Center, Ethiopia 3Haramay University, Ethiopia

Received: 02 November, 2016; Accepted: 09 November, 2016; Published: 11 November, 2016

Bekele Tesfaye, Sinana Agriculture Research Center (SARC), Ethiopia, E-mail:

Tesfaye B, Begna D, Eshetu M (2016) Evaluation of Physico-Chemical Properties of Honey Produced in Bale Natural Forest, Southeastern Ethiopia. Int J Agricultural Sci Food Technology 2(1): 021-027. DOI: 10.17352/2455-815X.000010

© 2016 Ibrahim, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Honey; Quality; Physico-chemical; Standard; Bale

The study was conducted to evaluate the physico-chemical properties of honey from Bale natural forest Southeastern of Ethiopia in 2014/15. For analysis thirty (30) honey samples each of 0.5 to 1 kg were obtained from three locations considering the different agro-ecologies of Bale and compared against to the national and international standards. The physico-chemical characters evaluated were: Color, Moisture Content, Ash, Free Acidity, pH, Hydroxy methyl furfural, Reducing Sugar, Sucrose Content and Electric Conductivity. Though there were some significant variation (P<0.05) between the different agro-ecologies, all samples collected were found in the range of the national and international standard limits. The means value of honey sample collected were Color 92.43 (Amber), Moisture Content (18.80), Ash (0.21), Free Acidity (32.43), pH (3.75), Hydroxy methyl furfural (36.35), Apparent Reducing Sugar (66.41), Sucrose Content (4.48) and Electric Conductivity (0.69). Results obtained in this study, indicate that honeys produced in Bale show excellent quality properties according to the national and international standards.

Introduction

Honey is produced in almost every country of the world. In Ethiopia, Bale is found in Oromia region, Southeastern part of the country where different flowering plant association or natural forests exist. It is very glorious which has unique and diverse fauna and floras in which dominant flowering plants exist. In the area the most known and common flowering plants found are: Cordia Africana, Croton Macrostacyus, Hygenia abyssinica, Olea europaea, Prunus Africana, Schefflera abyssinica, Vernonia amygdalina, Ziziphus Mauritian, Coffee arebica (Forest coffee), [1]. These plants are widely distributed in the area, showing two flowering seasons which ranges from December to February (Pick period) and June to August (Second pick period) and most of these plants are common honeybee flowers or honeybees forages.

Honey is the natural sweet substance produced by honeybees (Apis mellifera L.) from the nectar of blossoms or from secretions of living parts of plants or excretions of plant-sucking insects on the living parts of plants, which the bees collect, transform by combining with specific substances of their own, deposit, dehydrate, store and leave in honeycombs to ripen and mature [2].

The quality of honey is a key factor for both local and international markets [3], to enable attainment of competitive premium prices and ensure human health. Honey quality consideration is an aspect disregarded by producers and processors especially in developing countries. Proper understanding and standardization of honey components and attributes that are most vulnerable during processing cannot therefore be over emphasized. The major constituents of honey are sugars, water, proteins, enzymes, acids and minerals [4], while the major causes of quality deterioration include heating at high temperatures, high moisture content, adulteration, poor packaging and poor storage conditions [3].

Quality control of honey is important to determine its suitability for processing and to meet the demand of the market. The composition and quality of honey are greatly influenced by geographical and environmental factors [5]. It is also depend highly on the types of flowers utilized by bees as well as regional and climatic condition.

Physicochemical parameters of natural honeys, such as moisture content, ash, electric conductivity, pH and free acidity, hydroxy methyl furfural, apparent reducing sugar, sucrose content have been strictly defined and constitute the quality indicators characterizing individual honey varieties [6]. These mentioned factors vary by regional and climatic conditions [7]. To date, numerous studies have been done to determine the chemical properties of honey [6,8,9]. It is well known that the different honey types of the world show great variation in their physico-chemical properties and biological composition [10]. So, it is very important to study the physico-chemical composition of honey, which is greatly influenced by the geographical region, floral source and climate [5,10-12].

Therefore, the present study is aimed at determining the quality of various honeys produced in Bale natural forest in comparison with the Ethiopian Quality Standard Authority [13] and International honey standards of the Codex Alimentarius [14].

Materials and Methods

Description of the study area

The study was conducted in Bale Zone of Oromia Regional State which is located in Southeastern part of Ethiopia within 70, 00’N and 390 45’E and70, 30’N and 390, 30’E of latitude and longitude, respectively [15]. The study focuses on high, mid and low altitude where natural forests exists which includes Dinsho (070, 07’ and 390, 51’ latitude and longitude, respectively with 2860m altitudes), Dellomenna (060, 24’N and 390, 50’ latitude and longitude, respectively with 1278 m altitudes) and Adaba (070, 02’N and 390, 27’ E of latitude and longitude, respectively with 2386 m altitudes) districts. The districts were purposively selected for the study which representing different agro-ecologies of Bale Zone.

The study area had a mild subtropical highland with annual mean minimum and maximum temperature of 2oc and 20 oC, respectively [16]. Temperature tends to be severing with a high probability of frost during the night time particularly at higher altitude of Sannate, Dinsho and Rira areas. The area receives a bimodal rain fall [17]. The main rainy season extends from August to December and the short rainy season stretch from March to July. Rainfall is highly seasonal on the northern slopes of the mountains, with most of the mean annual rainfall occurring between July and September.

In the study area the most common flowering plants found are: Alnizia schimperiana, Azadirachta indica, Cajanus cajan, Cordia Africana, Croton Macrostacyus, Dombeya torri, Erica arborea,Eryythrina abyssinica, Hygenia abyssinica, Hypericum revoltum, Hypericum roeperianum, Moringa olefera, Nuxia congesta, Olea europaea, Prunus Africana, Schefflera abyssinica, Syzygium guineense, Vernonia amygdalina, Ziziphus Mauritian, Coffee arebica (Forest coffee), Erythrina brucei [1].

Sampling methods and honey quality analysis

To determine the quality of honey, honey samples of 0.5 - 1 kg was randomly collected from 30 beekeepers considering different agro-ecological variation. The collected samples were analyzed corresponds to the Quality Standard Authority of Ethiopia following the procedure of Codex Alimentarius Commission Standards [14]. Physical composition (color, moisture content, electric conductivity) and chemical compositions (pH, acidity, ash (mineral), HMF, reducing sugar and sucrose content) of the honey samples were determined according to the Harmonized Methods of the International Honey Commission [18,19]. The physical and chemical analyses were carried at Sinana Agricultural Research Center in Soil laboratory and Holeta Bee Research Center.

Quality control of honey is important to determine its suitability for processing and to meet the demand of the market. The composition and quality of honey are greatly influenced by geographical and environmental factors [5]. It is also depend highly on the types of flowers utilized by bees as well as regional and climatic condition. The purpose of the current honey quality study is to evaluate its quality and verify its agreement with the standards of national and international standards.

Honey color analysis

The color of honey samples was measured according to the Pfund classifier. Briefly, homogeneous honey samples free of air bubbles were transferred into a cuvette with a 10-mm light path until the cuvette was approximately half full. The cuvette was inserted into a color photometer Pfund honey color grader (No. 0061, made of USA) and the color grades were expressed in millimeter (mm) Pfund grades compared to an analytical grade glycerol standard following the procedure of Codex Alimentarius Commission Standards 14]. Measurements were performed for each sample using approved color standards of the United States Department of Agriculture [20].

Moisture content

The moisture content of honey was determined using the Refractive Index of the honey in reference to the standard Table (Appendix 1). The method was based on the principle that refractive index of the honey increases with solids content. A digital Abbe refractometer (ATAGO® 1211 NAR-1T Liquid Abbe refract meter with Refractive Index 1.3000 to 1.7000nD, Brix 0.0% to 95.0%, accuracy of refractive index (nD) ±0.0002 and Brix±0.1%, made of Japan) that could thermo stated at 20 oC regularly calibrated with distilled water was used. For this purpose, cleaned and dried prism of the Abbe refractometer was used. The surface of the prism was covered with homogenized honey samples. The refractive index after 2 minutes was read the corresponding moisture content from the Table. Water contents of sample were measured twice and the average value was recorded and it was done following the procedure of Codex Alimentarius Commission Standards [14]. The Table was derived from a formula developed by Wedmore [21], from the data of Chataway [22] and others:-

Where: W = the water content in g per 100 g honey and

R.I. = the refractive index

Mineral (ash) content

Ash content was determined after the sample was burnt in an electric muffle furnace (CFS 11/B, England). First the ash dish was cleaned and heated in the electrical furnace at 550 oC temperatures, subsequently cooled in a desecrator to room temperature and weighed to 0.001g (M2). Then, 5-10 grams of honey sample was weighed to the nearest 0. 001g (M0) and put in the prepared ash dish and two drops of olive oil was added to prevent frothing. Then, water was removed and commences ashing without loss (by foaming and overflowing) at a low heat rising to 350 - 400 oC by using electrical device. Bansun burner was used to char the sample before inserting into the furnace. After the preliminary ashing with Bansun burner, the dish was placed in the preheated muffle furnace (at 550oC) and heated for 1 hour. The ash dish was cooled in the desiccators and weighted. The ashing procedure was continued until constant weight was reached (M1). Percent ash in g/100g honey was calculated using the following formula, following the procedure of Codex Alimentarius Commission Standards [14].

Where: M0 = weight of honey taken,

M1 = weight of dish + ash and,

M2 = weight of dish.

pH and free acidity

Ten gram (10g) of honey samples was dissolved in 75 ml of carbon dioxide-free water (distilled water) in 250 ml beaker and stirred with the magnetic stirrer. Then the pH was measured with pH meter (3100 Janeway, England), calibrated at pH 4.0 and 7.0. The solution was further titrated with 0.1M sodium hydroxide (NaOH) solution to pH 8.30 (a steady reading was obtained within 2 minutes of starting the titration). For precision the reading to the nearest 0.2ml using a 10 ml burette were recorded. Free acidity, expressed as mill equivalents or mill moles of acid/kg honey was equal to ml of 0.1M NaOH x 10, and the result expressed to one place of decimals and done by following the procedure of Codex Alimentarius Commission Standards [14].

Acidity =10V, Where: V = the volume of 0.1N NaOH in 10 g of honey.

Hydroxy methyl furfural (HMF)

The determination of the hydroxyl methyl furfural (HMF) content was based on the determination of UV absorbance of HMF at 284 nm. In order to avoid the interference of other components at this wavelength, the difference between the absorbance of a clear aqueous honey solution and the same solution after addition of bisulphite was determined. The HMF content was calculated after subtraction of the background absorbance at 336 nm. Spectrophotometer operating in a wavelength range including 284 nm and 336 nm was used.

Accurately weigh 5 g of honey in small beaker and transfer with total of 25 ml distilled water to 50 ml volumetric flask. Then 0.5 ml of Carrez solution I was mixed with 0.5 ml of Carrez solution II and diluted to volume with distilled water and drop of alcohol was added to suppress foam. It was filtered through filter paper and the first 10 ml filtrate was discarded. Five ml filtrate was pipette into each of two 18 x 150 mm test tubes. Five ml of sample was pipetted out in two test tubes and 5 ml of water was added to the one test tube and mixed well. Five ml of 0.2 % sodium bisulphate solution was added to the second test tube and mixed well by using Vortex mixer for reference solution. The absorbance of the sample solution against the reference solution at 284nm and 336 nm in 10 mm quartz cells within one hour were determined. When the absorbance at 284 nm exceeds a value of about 0.6, the sample solution diluted with water and the reference solution with sodium bisulphite solution in order to obtain a sample absorbance low enough for accuracy following the procedure of Codex Alimentarius Commission Standards (2001). When dilution was necessary, the amount of needed solution added using dilution formula.

The dilution,

Calculation and expression of result, HMF in mg/kg = (A284 - A336) x 149.7 x 5 x D/W

Where: A284 = absorbance at 284 nm,

A336 = absorbance at 336

149.7 =

126 = molecular weight of HMF.

16830 = molar absorptivity and HMF at 284 nm.

10 = Conversion of g into mg.

1000 = Conversion of g into kg.

5 = Theoretical nominal sample weight.

D = Dilution factor, if dilution necessary

W = Mass of honey sample (g)

Total reducing sugar content (before and after inversion)

Reducing sugars were determined through reduction of Soxhlet’s modification of Fehling’s solution by titration at boiling point against a solution of reducing sugars in honey using methylene blue as an internal indicator. The difference in concentrations of invert sugar was multiplied by 0.95 to give the apparent sucrose content. This method was based on the original method of Lane and Eynon [23] and was also used in the Codex Alimentarius Standard [14].

Reducing sugar before inversion

Representative quantity of about 2 g (W2) of the homogeneous honey sample was dissolve in distilled water and dilute to 200 ml in a volumetric flask (honey solution). Then 50 ml of this honey solution was diluted to 100 ml using distilled water (diluted honey solution). Fifty ml of diluted honey solution was taken in the burette. Five ml Fehling’s solution A was pipetted into 250 ml Erlenmeyer flask and 5 ml Fehling’s solution B was added. Approximately 7 to 8 ml of distilled water was added and heated until it starts boiling. One ml of 0.2 % of methylene blue indicator was added and titration was completed during boiling only. The change in the color of the solution from blue to colorless was taken as the end point of the reaction. The percentage of total reducing sugar before inversion was calculated by the following formula as developed by Lane and Eynon [23].

Where: C = g total reduced sugar before inversion per 100 g honey

W2 = weight (g) of honey sample

Y2 = = volumes (ml) of diluted honey solution consumed

Reducing sugar after inversion

Fifty milliliter of honey solution, from the solution prepared for total reducing sugar before inversion was placed in a graduated flask, together with 25 ml distilled water, and heated to 65 oC over a boiling water bath. The flask was then removed from the heated bath and 10ml of hydrochloric acid was added. The solution was allowed to cool naturally for 15 minutes, and then brought to 20 oC and neutralized with sodium hydroxide, using litmus paper as indicator, cooled again, and the volume adjusted to 100 ml (diluted honey solution). Then 5 ml of Fehling A, 5 ml of Fehling B and 7 - 8 ml of distilled water was taken in a 250 ml conical flask and heated till it starts boiling. After boiling, 1 ml of 0.2 % of methylene blue indicator was added to the flask. The titration was completed while the solution is boiling. The end point of the reaction was recorded as the blue color changed to colorless. The percentage of total reducing sugar was calculated by the following formula and following the procedure of Codex Alimentarius Commission Standards [14].

c

Where: C = g total reduced sugar after inversion per 100 g honey

W2 = weight (g) of honey sample

Y2 = = volumes (ml) of diluted honey solution consumed

Apparent sucrose

The %age of sucrose was calculated as follows:

Apparent sucrose content = (reducing sugar content after inversion - reducing sugar

Content before inversion) x0.95

The result was expressed as g apparent sucrose per 100 g honey, following the procedure of Codex Alimentarius Commission Standards [14].

Electrical conductivity

Twenty grams of honey (on dry matter basis) were dissolved in distilled water and transferred to a 100 ml volumetric flask, and made up to volume with distilled water. 40 ml of this solution was poured into a beaker and placed in thermo stated water bath at 20 °C. Electrical conductivity measurements were obtained with a low range conductivity meter (4310 Wagtech, England) with a cell constant of 1.03. The conductivity cell was there after immersed in the sample solution and the conductance in mS read after temperature equilibrium had been reached. Electrical conductivity was calculated using the formula following the procedure of Codex Alimentarius Commission Standards [14].

SH = K. G, Where: SH = electrical conductivity of the honey solution in mS.cm-1

K = cell constant in cm-1

G = conductance in mS

The results were expressed to the nearest 0.01 mS.cm-1

Statistical analysis

All analysis was performed in triplicate and data was expressed as mean standard errors (±). Least significance difference at P<0.05 level was used to separate the means whenever ANOVA showed statistically significant difference using one-way analysis of variance (ANOVA).

Results

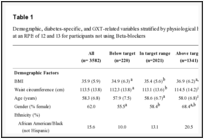

The results of physico-chemical analysis of 30 (thirty) honey samples obtained from different agro-ecologies of Bale natural forest in three districts within the Southeastern part of Ethiopia are presented in Table 1. The results showed no significant differences (P>0.05) between the samples obtained from three agro-ecologies for ash contents, Free acidity and Reducing sugar. However, significant differences (P<0.05) in Honey color, Moisture contents, pH, Hydroxyl methyl furfural (HMF), Apparent sucrose and Electric conductivity were observed between the honey samples collected from the three locations.

The greatest color of honey sample studied on Pfund value was observed at Dinsho (140 mm Pfund) or dark amber and the lowest Pfund value was observed at Adaba (20 mm pfund) or white color. The most frequent color observed were: light amber, dark amber, extra light amber honey colors (Table 2). The moisture contents of all honey samples studied ranged from 14.60 to 22.8% with mean value 18.50% (Table 1). The average Ash values obtained were 0.20, 0.22 and 0.20 %, for honeys from Ababa, Dinsho and Dellomenna districts, respectively (Table 1). The average free acidity values obtained were 29.55, 36.09 and 31.64 meq kg-1, for honeys from Ababa, Dinsho and Dellomenna districts, respectively (Table 1). The greatest pH values were obtained for honeys from Dellomenna district, while the lowest values were observed in honeys from Ababa district (Table 1). The greatest HMF was recorded at Ababa district and the lowest observed at Dinsho district with the overall mean of 36.35mg/kg (Table 1). The reducing sugar of honey samples studied was ranged from 51.28 to 69.20 with average of 66.41%. The greatest apparent sucrose was obtained from Dinsho district but no variation between samples taken from Adaba and Dellomenna districts with overall mean of 4.48 values. Electrical conductivity values ranged from 0.22 to 1.34 mS cm-1 and with mean value f 0.69 mS cm-1 (Table 1).

-

Table 2:

Honey color classification according to U.S Department of Agriculture Standard.

Discussions

The quality parameters evaluated in this study indicated values in agreement with national and international requirements [13,24]. The most important aspects of honey color bring into being in its value for marketing determination to its end users. Usually honey color changes may result from the beekeeper’s interventions and different ways of handling of combs such as the use of old honeycombs, contact with metals and exposure to high temperatures and also honey color changes with advance in storage time. But the color of untreated honey depends on its botanical origins. Consumers’ preferences are determined by the color of honey and thus, next to general quality determinations, color is the single most important factor determining import and whole sale prices [25,26]. In the current study, honey sample color from Dinsho was significant (P<0.05) higher on pfund scale than that from Adaba and Dellomenna districts. But, there were no significant variation (P>0.05) between sample from Adaba and Dellomenna districts. However, the overall honey color ranged from 20 to 140 mm Pfund scale or white to dark amber color. The greatest Pfund value was observed at Dinsho (140 mm Pfund) or dark amber and the lowest Pfund value was observed at Adaba (20 mm pfund) or white color. Out of the 30 sample collected 33.3% was light amber and followed by 30% dark amber color but the remaining sample was 23.3%, 3.3%, and 10% amber, extra light amber and white, respectively. Aloisis P [27]. states similar result as the color of honey varied according to the melliferous area from Argentina.

Moisture content is one of the important parameter to be considered in the quality of honey. Honey is an excellent hygroscopic product and has tendency to absorb atmospheric moisture and thus readily increase its moisture levels. Further, the moisture levels may also largely depend on methods of harvesting and extraction of honey which may differ from location, species and practices [24]. Mean moisture (% by mass) content of honey in Dinsho (19.94) was significantly higher (P<0.05) than that of Dellomenna (17.96), but there was no significant difference (P>0.05) in moisture content of honey from Ababa (18.50). The greater honey moisture content observed at Dinsho was because of high relative humidity found at Dinsho. However; the overall mean moisture content of honey in the study area was 18.80 which were found between the range of national and international standard limit. The present results agree with results of Nuru Adgaba [28] that reported 20.5% as mean test result for Ethiopian honey and [29]. that reported 18.80% mean of honey moisture content from Burie District of Amhara Region.

The ash percentage found in honey expresses its richness in mineral content and constitutes a quality parameter [30]. In this study, it can be seen that honey from all the studied districts showed 0.21 mean ashes percentage below the allowable maximum and thus conform to the international regulatory standards for quality honey [24]. But, there was no significant difference (P>0.05) in ash content of honey samples from all districts and ranged between 0.14 – 0.30. The result is consistent with [28], who reported 0.1-1.0% ash content of honey samples of Ethiopia. This result is also agreed with findings of [29,31,32]. Therefore, the result of current study revealed that honey produced in Bale was floral honey which is good for consumption and industrial purposes.

When the acidity becomes high, the honey becomes sour. The recommended acidity of honey is usually less than 40 meq acid/kg of honey [14]. It was observed that there was no significant variation (P>0.05) in free acidity among the honey samples from the three locations (Dinsho, Adaba and Dellomaenna) but it was ranged from 13 - 46 meq kg−1 and with mean of 32.43 meq kg−1 value, which was in accordance with the observation made by Nuru, Gebreegziabher et al., Legesse [28,31,32].

All honeys are acidic with a pH-value generally lying between 3.5 and 5.5, due to the presence of organic acids that contribute to honey flavor and stability against microbial spoilage [33]. This parameter has of great significance during the extraction and storage of honey as it influences the texture, stability and shelf life of honey [34]. The average pH of honey in Dellomenna (3.92) was significantly higher (P<0.05) than that of Adaba (3.54), but there was no significant difference (P>0.05) from Dinsho (3.79). The overall mean results were 3.75 and with 3.30 minimum and 4.85 maximum value. This result agrees with the result of [29,35]. Therefore, in the current result the low pH of honey confirms that it well inhibits the presence and growth of micro-organisms and makes honey compatible with many food products in terms of pH and acidity.

One of the most commonly monitored parameters for determining honey freshness and good practices by beekeepers are HMF [24,30,33]. In fresh honey, HMF is present only in small amounts and its concentration increases with storage time and prolonged heating of honey. The hydroxyl methyl furfural (HMF) content of the honey samples analyzed in the present study ranged from 27.10 to 40.80 mg/kg with overall mean value 36.35 mg/kg. The average HMF value of Adaba (38.81mg/kg) was significantly (P<0.05) higher than Dinsho (33.86mg/kg), but there were no significant difference between Adaba and Dellomenna, Dinsho and Dellomenna districts. The reported results are in agreement with the referred by [28], that established 32.4mg KOH/kg as mean test result of Ethiopian honey and studies conducted by [29,35].

Honey is a mixture of principally two reducing sugars namely glucose and fructose, giving it similar properties to invert syrup. This gives it the ability to remain liquid for long periods of time. Determination of sugars in honey is a quality criteria which is influenced by honey storage and heating and thus is an indicator of honey freshness and overheating. The result indicated that there were no significant difference (P>0.05) in apparent reducing sugar contents in honey collected from Adaba, Dinsho and Dellomenna districts. However, the overall mean of apparent reducing sugar was 66.41% and with minimum 51.28% and maximum 69.20%. Comparison between samples collected showed that about 90% and 96.67% met the quality standard of national and international limit respectively and only few 10% and 3.33% did not. Nuru Adgaba [28]. reported 65.5% as mean reducing sugar content of honey produced in Ethiopia. Different researched reported similar finding [29,31,32,35].

It is known that the level of sucrose differs according to the maturity degree and origin of the nectar compound of the honey and also used to detect adulteration of honey by addition of cane or other sugars. Added sugar in honey can be detected by measuring sucrose content [33]. The analyzed results of the honey collected in this study showed that the average of apparent sucrose of honey from Adaba (3.52%) was significantly lower than that of honey from Dinsho (5.41%) and Dellomenna (4.50%). However, the overall mean apparent sucrose was 4.48% and ranged between 3.01 % to 7.62. The mean apparent sucrose content of the study areas honey was also higher (4.48%) than the national average of 3.6% which was reported by [28]. The present result is lower than [35], who reported 7.55 mean for the honey from Gomma district. The result revealed that honey produced by Bale beekeepers is natural and free of any adulteration.

Electric conductivity is the indication of ionizable acids and compounds in aqueous solution and it is a good criterion to know the botanical origin honey, the higher their content the higher the resulting conductivity. Almost all of the samples presented electrical conductivity values characteristic of nectar honey (≤ 0.8 mS cm-1) [24], with the greatest records obtained in honeys from Dinsho district. The electric conductivity values in the investigated honey samples from the three locations varied in the range 0.22 - 1.34mS.cm-1 with overall average value of 0.69mS.cm-1. The great differences between honeys in electric conductivity in the three locations indicated existences of different flora species in each locality. Similar result has been reported for the honey produced from different floral sources at Malaysia with mean 0.74 mS/cm and 0.41 mS/cm minimum and 0.79 mS/cm maximum values [36].

Conclusions

The analytical laboratory result revealed that the honey produced in Bale natural forest was from nectars of blossoms of flowering plants and found excellent quality characters according the national and international honey quality standards.

Acknowledgements

We would like to acknowledge the Sinana Agricultural Research Center for material and financial supports. We also great fully thank Mr. Shure Soboka of Soil team of Sinana Agricultural Research Center Researcher for his unconscious support and devoting much of his time with us in laboratory analysis of honey quality.

- Sinana Agricultural Research Center (SARC) (2014) Information Bulletin on Major Achievements of SARC.

- Council Directive of the European Union (2002) Council Directive 2001/110/EC of 20 December 2001 relating to honey. Official Journal of the European Communities. L10: 47-52 .

- Krell R (1996) Value added products from bee keeping. FAO Agricultural Services Bulletin, 124. Food and Agricultural Organization of the United Nations. Rome, Italy, 371 .

- Food and Agriculture Organization (FAO) (19960 Value added products from beekeeping (FAO Agricultural Services Bulletin No., 124). Rome, Italy .

- Jones SL, Jones HR, Thrasyvoulou A (2011) Disseminating research about bee products. A review of articles published in the Journal of Apicultural Research over the past fifty years. Journal of Apiculture Product and Apicultural Medical Science 3: 105-116 .

- Juszczak LR, Socha J, Ro_znowski, Fortuna T, Nalepka K (2009) Physicochemical properties and quality parameters of herbhoneys. Food Chemistry 113: 538-542 .

- Lazaridou A, Biliaderis CG, Bacandritsos N, Sabatini AG (2004) Composition, thermal and rheological behavior of selected Greek honeys. Journal of Food Engineering 64: 9-21 .

- Rodríguez GO, Ferrer BS, Ferrer A, Rodríguez B (2004) Characterization of honey produced in Venezuela. Food Chemistry 84: 499-502 .

- Ajlouni S, SujirapinyokulP (2010) Hydroxymethylfurfuraldehyde and amylase contents in Australian honey. Food Chemistry 119: 1000-1005 .

- Muli E, Munguti A,Raina SK (2007) Quality of honey harvested and processed using traditional methods in rural areas of Kenya. Acta Vet.Brno 76: 315-320 .

- Anklam E (1998) A review of the analytical methods to determine the geographical and botanical origin of honey. Food Chemistry 63: 549-562 .

- Joseph T, Awah-Ndukum J, Fonteh-Florence A, Delphine ND, Jonnas Pet al. (2007) Physico-chemical and microbiological characteristics of honey from the Sudano-Guinean Zone of west Cameron. African Journal of Biotechnology 6: 908-913 .

- QSAE (2005) Ethiopian Standard, Honey-Specification. First edition.

- Codex Alimentarius (2001) Revised Codex Standard for Honey, Codex STAN 12–1981, Rev. 1 (1987), Rev. 2 .

- Ethiopian Mapping Authority (1988) National Atlas of Ethiopia, first edition people’s Democratic Republic of Ethiopia. Berhanna Selam Printing Press, Addis Ababa, Ethiopia.

- Williams S (2002) Bale Mountains: a guidebook. United Printers, Addis Ababa, Ethiopia. 52.

- Sinana Agricultural Research Center (SARC) (2001) Profile of Sinana Agricultural Research Center (SARC). Oromia Agricultural Research Institute. Working Document Series 1, Addis Ababa, Ethiopia.

- Bogdanov S (2002) Harmonized Methods of the International Honey Commission. A Review, Swiss Bee Research Centre FAM, Liebefeld, CH-3003 Bern, Switzerland .

- Geremew Bultosa (2005) Food chemistry laboratory manual. Department of food science and post harvest technology, Alemaya University, Ethiopia.

- USDA (1985) United States standards for grades of extracted honey. Washington, DC: Agricultural Marketing Service Fruit and Vegetable Division Processed Products Branch .

- Wedmore EB (1955) The accurate determination of the water content of honeys. Bee World 36: 197- 206 .

- Chataway HD (1923) Canadian Journal of Research, 6: 532-547.

- Lane JH, Eynon L (1923) Determination of reducing sugars by means of Fehling’s solution with methylene blue as international indicator. J Soc Chem Ind Trans 32-36 .

- Bogdanov S, Lûllman C, Martin P, W von der Ohe, Russman H, et al. (1999) Honey quality and international regulatory standards: Review by the International Honey Commission. Mitteilungen aus Leben smitteluntersuchung und Hygiene 90: 108-125 .

- White JW (1975) Honey in the hive and the honey bee. Dadant and Sons Inc., Hamilton Illionois, USA 491-530 .

- Crane B (1980) A book of honey. Oxford University press, Oxford UK 198.

- Aloisi PV (2010) Determination of Quality Chemical Parameters of Honey from Chubut (Argentinean Patagonia). Chilean Journal of Agricultural Research 70: 640-645 .

- Adgaba N (1999) Quality state of grading Ethiopian honey. In: Proceedings of the first National conference of the Ethiopian Beekeepers Association, Addis Ababa, Ethiopia.

- Belie T (2009) Honeybee Production and Marketing Systems, Constraints and Opportunities in Burie District of Amahara Region, Ethiopia. M.Sc. Thesis .

- Marchini LC, Moretti AC, Otsuki IP, Sodré G (2007) Physicochemical composition of Apis mellifera honey samples from São Paulo state, Brazil. Quimica Nova 30: 1653-1657 .

- GY Legesse (2014) Review of progress in Ethiopian honey production and marketing. Holeta Bee Research Center (HBRC), Holeta. P.O. Box 22 Ethiopia .

- Gebremedhin G, Tadesse G, Kebede E (2013) Physiochemical characteristics of honey obtained from traditional and modern hive production systems in Tigray region, northern Ethiopia 5: 115-128.

- Adebiyi FM, Akpam I, Obiajunwa ET, Olaniyi HB (2004) Chemical physical characterization of Nigeria Honey. Pakistan Journal of Nutrition 3: 278-281 .

- Kinat C (2010) Honey Production, Marketing System and Quality Assessment in Gomma Woreda, South Western Ethiopia.

- Bogdanov S, Martin P (2002) Honey authenticity. In: Mitteilungenaus den Gebieteder lebensmitteluntersuchungund hygiene 93: 232-254 .Moniruzzaman M, Sulaiman SA, Khalil MI, Gan SH (2013) Evaluation of physicochemical and antioxidant properties of sourwood and other Malaysian honeys: a comparison with manuka honey. Chem Cent J 7: 138 .

Table 1:

Mean comparison of physicochemical properties of honey samples collected from three agro-ecologies of Bale natural forests and Compared to National and International standards (N=30).

Table 1: Mean comparison of physicochemical properties of honey samples collected from three agro-ecologies of Bale natural forests and Compared to National and International standards (N=30)

Locations (Mean ±SE)

Over all

Standards*

Parameter

Adaba (n=10)

Dinsho (n=10)

D/menna (n=10)

Mean

Range

National

International

Color (mm pfund)

68.30±10.87b

118.0±6.91a

91.0±9.24b

92.43±6.34

20 - 140

-

-

MC (%)

18.50±0.53ab

19.94±0.62a

17.96±0.59b

18.80±0.36

14.60 – 22.8

17.5 – 21

18 – 23

Ash (%)

0.20±0.012

0.22±0.015

0.20±0.010

0.21±0.007NS

0.14 – 0.30

<0.6

0.25 - 1.0

FA(meq/kg)

29.55±1.63

36.09±1.52

31.64±4.01

32.43±1.56NS

13 – 46

<40

<50

PH

3.54±0.06b

3.79±0.06ab

3.92±0.15a

3.75±0.06

3.3 – 4.85

-

3.2 - 4.5

HMF (mg/kg)

38.81±0.56a

33.86±0.77b

36.36±1.48ab

36.35±0.68

27.10-40.80

<40

<80

RS (%)

66.41±0.34

65.45±1.64

67.53±0.21

66.41±0.57NS

51.28 – 69.20

>65

60 – 70

AS (%)

3.52±0.12b

5.41±0.51a

4.57±0.27ab

4.48±0.24

3.01 – 7.62

<5

<10

EC(mScm-1)

0.39±0.05c

1.05±0.07a

0.63±0.10b

0.69±0.06

0.22 – 1.34

-

0.22- 1.52

abc= means with different superscripts within a row are significantly different (P<0.05), N=Number of sample SE= Standard Error

Notice: MC =moisture content, Ash = Total ash content FA = Free acidity, PH =PH, HMF = hydroxyl methyl furfural

RS = Reducing sugar, AS = Apparent Sucrose, EC = Electric conductivity,

*Source: Quality and Standards Authority of Ethiopia (2005).