Abstract

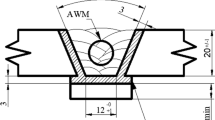

A 9% Cr ferritic steel weld metal containing 1% Co, partially substituted for nickel, was prepared by submerged arc welding (SAW) processing. The microstructure and creep properties of the weld metal were investigated. The microstructure exhibited a fully tempered martensitic structure free of δ-ferrite. The creep properties of the obtained weld metal were inferior to those of the P92 base metal at 600 and 650 °C. The values of A and n for weld metal in the Norton power law constitution at 650 °C are 1.1×10−21 and 8.1, respectively.

Similar content being viewed by others

References

Barnes, A., Abson, D., 2003. The Effect of Composition on Microstructural Development and Toughness of Weld Metals for Advanced High Temperature 9–13%Cr Steels. 2nd International Conference Intergrity of High Temperature Welds, IOM Communications Ltd., London.

Baune, E., Cerjak, H., Caminada, S., Jochun, C., Mayr, P., Pasternak, J., 2006. Weldability and Properties of New Creep Resistant Materials for Use in Ultra Supercritical Coal Fired Power Plants. 8th International Conference Materials for Advanced Power Engineering, Forschungszentrum Jülich GmbH, Liege, Germany.

Bendick, W., Deshayes, F., Haarmann, K., Vaillant, J.C., 1999. New 9–12Cr Steels in Boiler Tubes and Pipes: Operating Experiences and Future Developments. In: Viswanathan, R., Nutting, J., (Eds.), Advanced Heat Resistant Steels for Power Generation, IOM Communications Ltd., London, p.133.

Brühl, 1989. Verhalten des 9%-Chromstahles X10CrMoVNb91 und Seiner Schweißverbindungen im Kurz-und Langzeitversuch. PhD Thesis, Graz, Austria (in German).

Foldyna, V., Purmenský, J., Kubon, Z., 2001. Development of advanced chromium steels with respect to microstructure and structural stability. ISIJ International, 41(Suppl.): 81–85.

Kern, T.U., Staubli, M., Scarlin, B., 2002. The European efforts in material development for 650 °C USC power plants—COST522. ISIJ International, 42(12):1515–1519.

Kimura, K., Sawada, K., Kushima, H., Toda, Y., 2006. Degradation Behaviour and Long-term Creep Strength of 12Cr Ferritic Creep Resistant Steels. 8th International Conference Materials for Advanced Power Engineering, Forschungszentrum Jülich GmbH, Liege, Germany.

Klotz, U.E., Solenthaler, C., Uggowitzer, P.J., 2008. Martensitic-austenitic 9–12% Cr steels—Alloy design, microstructural stability and mechanical properties. Materials Science and Engineering: A, 476(1–2):186–194. [doi:10.1016/j.msea.2007.04.093]

Knežević, V., Balun, J., Sauthoff, G., Inden, G., 2008. Design of martensitic/ferritic heat-resistant steels for application at 650 °C with supporting thermodynamic modeling. Materials Science and Engineering: A, 477(1–2):334–343. [doi:10.1016/j.msea.2007.05.047]

Letofsky, E., 2001. Das Verhalten von Schweißverbindungen moderner Kraftwerkswerktoffe. PhD Thesis, Graz University of Technology, Austria (in German).

Maruyama, K., Sawada, K., Koike, J., 2001. Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ International, 41(6):641–653.

Masuyama, F., 2001. History of power plants and progress in heat resistant steels. ISIJ International, 41(6):612–625.

Masuyama, F., 2002. New Developments in Steels for Power Generation Boilers. In: Viswanathan, R., Nutting, J., (Eds.), Advanced Heat Resistant Steels for Power Generation, IOM Communications Ltd., London, p.33.

Naoi, H., Mimua, H., Ohgami, M., Morimoto, H., Tanaka, T., Yazaki, Y., 1995. NF616 Pipe Production and Properties and Welding Consumable Development. Conference New Steels for Advanced Plant up to 620 °C, EPRI, London.

Santella, M.L., Swindeman, R.W., Reed, R.W., Tanzosh, J.M., 2003. Martensite Transformation, Microsegregation, and Creep Strength of 9Cr-1Mo-V Steel Weld Metal. 6th International Trends in Welding Research Conference Proceedings, Pine Mountain, GA, ASM International.

Sireesha, M., Albert, S.K., Sundaresan, S., 2001. Importance of filler material chemistry for optimizing weld metal mechanical properties in modified 9Cr-1Mo steel. Science and Technology of Welding and Joining, 6(4): 247–254.

Vaillant, J.C., Vandenberghe, B., Hahn, B., Heuser, H., Jochum, C., 2008. T/P23,24,911 and 92: New grades for advanced coal-fired power plants—Properties and experience. International Journal of Pressure Vessels and Piping, 85(1–2):38–46. [doi:10.1016/j.ijpvp.2007.06.011]

Yamashita, K., Goto, A., 2003. Welding consumables of high Cr ferritic heat resisting steels for fossil fuel power boilers. KOBE Steel Engineering Reports, 53(2):79–84.

Author information

Authors and Affiliations

Corresponding author

Additional information

Project (No. 51074113) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Wang, X., Zhan, Lf., Pan, Qg. et al. Microstructure and creep properties of high Cr resisting weld metal alloyed with Co. J. Zhejiang Univ. Sci. A 11, 756–760 (2010). https://doi.org/10.1631/jzus.A1000215

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1000215