Abstract

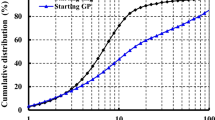

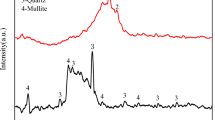

This study investigates the potential use of basalt powder as a sole precursor or blended in high amounts in slag-based alkali-activated systems. Eight alkali-activated mixes are prepared and comprehensively analyzed to determine the compressive strength development and microstructural characterization of basalt powder-based and basalt powder/slag blends activated by sodium hydroxide and a mixture of sodium hydroxide and sodium silicate. The mixes are characterized from a microstructural viewpoint via X-ray diffraction, Fourier transform infrared spectroscopy, thermogravimetric and scanning electron microscopy analyses. The results show that while basalt powder-based mixes have low compressive strength values, ranging between 2 and 9 MPa, basalt powder/slag blend mixes exhibit a moderate compressive strength, i.e., 20 MPa at 28 days. Furthermore, sodium-silicate-activated basalt powder/slag blend mixes achieve high compressive strengths at early and further ages. The low strength values of the basalt powder-based mixes are attributed to the low concentration of reactive species and lack of Ca2+ ions in the medium, while the high compressive strength of the blended mixes is mainly associated with the formation of calcium aluminosilicate hydrate [C–(A)–S–H] or Na-enriched calcium sodium aluminosilicate hydrate [C–(N)–A–S–H] gel phases along with the calcic-plagioclase, which afford a denser microstructure. The obtained results show that basalt powder can be used in high concentrations, i.e., 50%, in alkali-activated systems, and basalt powder/slag blends can be a feasible, alternative binder system for use as a structural material.

Similar content being viewed by others

Data availability

All data, models, and code generated or used during the study appear in the submitted article.

References

Bondar D, Lynsdale CJ, Milestone NB (2013) Alkali-activated natural pozzolan concrete as new construction material. ACI Mater J 110:331

Davidovits J (2008) Geopolymer chemistry and applications. Institute Geopolymer, Saint-Quentin

Duxson P, Fernández-Jiménez A, Provis JL, Lukey GC, Palomo A, van Deventer JSJ (2007) Geopolymer technology: the current state of the art. J Mater Sci 42:2917–3233. https://doi.org/10.1007/s10853-006-0637-z

Djobo JNY, Elimbi A, Tchakouté HK, Kumar S (2016) Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr Build Mater 124:606–614. https://doi.org/10.1016/j.conbuildmat.2016.07.141

Pilehvar S, Szczotok AM, Rodríguez JF, Valentini L, Lanzón M, Pamies R, Kjøniksen A-L (2019) Effect of freeze-thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr Build Mater 200:94–103. https://doi.org/10.1016/j.conbuildmat.2018.12.057

Aydın S, Baradan B (2012) Mechanical and microstructural properties of heat cured alkali-activated slag mortars. Mater Des 35:374–383. https://doi.org/10.1016/j.matdes.2011.10.005

Lemougna PN, ChinjeMelo UF, Delplancke M-P, Rahier H (2014) Influence of the chemical and mineralogical composition on the reactivity of volcanic ashes during alkali activation. Ceram Int 40(1):811–820. https://doi.org/10.1016/j.ceramint.2013.06.072

Barrie E, Cappuyns V, Vassilieva E, Adriaens R, Hollanders S, Garcés D, Paredes C, Pontikes Y, Elsen J, Machiels L (2015) Potential of inorganic polymers (geopolymers) made of halloysite and volcanic glass for the immobilisation of tailings from Gold extraction in Ecuador. Appl Clay Sci 109–110:95–106. https://doi.org/10.1016/j.clay.2015.02.025

Tchakouté HK, Kong S, Djobo JNY, Tchadjié LN, Njopwouo D (2015) A comparative study of two methods to produce geopolymer composites from volcanic scoria and the role of structural water contained in the volcanic scoria on its reactivity. Ceram Int 41(10):12568–12577. https://doi.org/10.1016/j.ceramint.2015.06.073

Erdogan ST (2015) Properties of ground perlite geopolymer mortars. J Mater Civ Eng 27:04014210. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001172

Kani EN, Allahverdi A, Provis JL (2012) Efflorescence control in geopolymer binders based on natural pozzolan. Cem Concr Compos 34(1):25–33. https://doi.org/10.1016/j.cemconcomp.2011.07.007

Dali Bondar CJ, Lynsdale NB, Milestone N, Hassani AAR (2011) Effect of type, form, and dosage of activators on strength of alkali-activated natural pozzolans. Cem Concr Compos 33(2):251–260. https://doi.org/10.1016/j.cemconcomp.2010.10.021

Esaifan M, Hourani M, Khoury H, Rahier H, Wastiels J (2017) Synthesis of hydroxysodalite zeolite by alkali-activation of basalt powder rich in calc-plagioclase. Adv Powder Technol 28(2):473–480. https://doi.org/10.1016/j.apt.2016.11.002

Gill R (2011) Igneous rocks and processes: a practical guide. John Wiley & Sons Ltd

Unčík S, Kmecová V (2013) The effect of basalt powder on the properties of cement composites. Proc Eng 65:51–56. https://doi.org/10.1016/j.proeng.2013.09.010

Marfil SA, Maiza PJ, Bengochea AL, Sota JD, Batic OR (1998) Relationships between SiO2, Al2O3, Fe2O3, CaO, K2O, and expansion in the determination of the alkali reactivity of basaltic rocks. Cem Concr Res 28(2):189–196. https://doi.org/10.1016/S0008-8846(97)00249-4

Korkanç M, Tuğrul A (2005) Evaluation of selected basalts from the point of alkali–silica reactivity. Cem Concr Res 35(3):505–512. https://doi.org/10.1016/j.cemconres.2004.06.013

Çopuroğlu O, Andiç-Çakir Ö, Broekmans MATM, Kühnel R (2009) Mineralogy, geochemistry and expansion testing of an alkali-reactive basalt from western Anatolia, Turkey. Mater Charact 60(7):756–766. https://doi.org/10.1016/j.matchar.2008.09.011

Saraya ME-SI, El-Fadaly E (2017) Preliminary study of alkali activation of basalt: effect of NaOH concentration on geopolymerization of basalt. J Mater Sci Chem Eng 05(11):58–76. https://doi.org/10.4236/msce.2017.511006

Venyite P, Makone EC, Kaze RC, Nana A, Nemaleu JGD, Kamseu E, Melo UC, Leonelli C (2022) Effect of combined metakaolin and basalt powder additions to laterite-based geopolymers activated by rice husk ash (RHA)/NaOH solution. SILICON 14(4):1643–1662. https://doi.org/10.1007/s12633-021-00950-7

Ke G, Shen H, Yang P (2019) Synthesis of X-Zeolite from waste basalt powder and its influencing factors and synthesis mechanism. Materials 12:3895. https://doi.org/10.3390/ma12233895

Akturk B, Kızılkanat, AB, Kabay, N, Akyuncu, V (2021) Utilization of basalt powder as geopolymeric binder. In: International Conference Cement - Based Materials Tailored a Sustainable Future, Istanbul, pp. 491–497. https://www.researchgate.net/profile/Busra-Akturk-3/publication/357484979_Utilization_of_Basalt_Powder_as_Geopolymeric_Binder/links/61d08405da5d105e5511e3e4/Utilization-of-Basalt-Powder-as-Geopolymeric-Binder.pdf

T.S. Institute (2009) TS 25-Turkish Standards-Natural pozzolan (Trass) for use in cement and concrete - Definitions, requirements and conformity criteria, Ankara

BS E-196-2 (2013) Methods of testing cement Chemical analysis of cement

ASTM C1437 (2016) Standard test method for flow of hydraulic cement mortar. Am Soc Test Mater. https://doi.org/10.1520/C1437-15.2

ASTM C191 (2013) Standard test method for time of setting of hydraulic cement by Vicat Needle. ASTM Int. https://doi.org/10.1520/C0191-13.2

ASTM C109, ASTM C109/C109M-21, standard test method for compressive strength of hydraulic cement mortars ( Using 2-in. or [ 50-mm ] Cube Specimens ) 1, ASTM Int. West Conshohocken, PA (2021). https://doi.org/10.1520/C0109

Fang G, Ho WK, Wenlin T, Zhang M (2018) Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr Build Mater 172:476–487. https://doi.org/10.1016/j.conbuildmat.2018.04.008

Bakharev T, Sanjayan JG, Cheng Y-B (2000) Effect of admixtures on properties of alkali-activated slag concrete. Cem Concr Resear 30(9):1367–1374. https://doi.org/10.1016/S0008-8846(00)00349-5

Deb PS, Nath P, Sarker PK (2014) The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater Des 62:32–39. https://doi.org/10.1016/j.matdes.2014.05.001

Aydın S, Baradan B (2014) Effect of activator type and content on properties of alkali-activated slag mortars. Compos Part B Eng 57:166–172. https://doi.org/10.1016/j.compositesb.2013.10.001

Rajaokarivony-Andriambololona S,Thomassin JH, Baillif P, Touray JC (1990) Experimental hydration of two synthetic glassy blast furnace slags in water and alkaline solutions (NaOH and KOH 0.1 N) at 40 °C: structure, composition and origin of the hydrated layer. J Mater Sci 25:2399–2410

Fernandez-Jimenez A, Puertas F (2001) Setting of alkali-activated slag cement. Influence of activator nature. Adv Cem Res 13(3):115–121. https://doi.org/10.1680/adcr.13.3.115.39288

Laskar SM, Talukdar S (2017) Development of ultrafine slag-based geopolymer mortar for use as repairing mortar. J Mater Civ Eng 29:04016292. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001824

Malkawi AB, Nuruddin MF, Fauzi A, Almattarneh H, Mohammed BS (2016) Effects of alkaline solution on properties of the HCFA geopolymer mortars. Proc Eng 148:710–717. https://doi.org/10.1016/j.proeng.2016.06.581

Karakoç MB, Türkmen I, Maraş MM, Kantarci F, Demirboğa R, Toprak U (2014) Mechanical properties and setting time of ferrochrome slag based geopolymer paste and mortar. Constr Build Mater 72:283–292. https://doi.org/10.1016/j.conbuildmat.2014.09.021

Temuujin J, Williams RP, van Riessen A (2009) Effect of mechanical activation of fly ash on the properties of geopolymer cured at ambient temperature. J Mater Process Technol 209(12–13):5276–5280. https://doi.org/10.1016/j.jmatprotec.2009.03.016

Li N, Shi C, Zhang Z (2019) Understanding the roles of activators towards setting and hardening control of alkali-activated slag cement. Compos Part B Eng 171:34–45. https://doi.org/10.1016/j.compositesb.2019.04.024

Lee NK, Lee HK (2013) Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr Build Mater 47:1201–1209. https://doi.org/10.1016/j.conbuildmat.2013.05.107

Mustafa Al Bakri AM, Karamudin H, Binhussain M, Rafiza AR, Zarina Y (2012) Effect of Na2SiO3/NaOH ratios and NaOH molarities on compressive strength of fly-ash-based geopolymer. ACI Mater J 109:503–508

Somna K, Jaturapitakkul C, Kajitvichyanukul P, Chindaprasirt P (2011) NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 90(6):2118–2124. https://doi.org/10.1016/j.fuel.2011.01.018

Akturk B, Kizilkanat AB, Kabay N (2019) Effect of calcium hydroxide on fresh state behavior of sodium carbonate activated blast furnace slag pastes. Constr Build Mater 212:388–399. https://doi.org/10.1016/j.conbuildmat.2019.03.328

Xu H, van Deventer JSJ (2000) The geopolymerisation of alumino-silicate minerals. Int J Miner Process 59:247–266. https://doi.org/10.1016/S0301-7516(99)00074-5

Escalante-García JI, Fuentes AF, Gorokhovsky A, Fraire-Luna PE, Mendoza-Suarez G (2003) Hydration products and reactivity of blast-furnace slag activated by various alkalis. J Am Ceram Soc 86:2148–2153. https://doi.org/10.1111/j.1151-2916.2003.tb03623.x

Ben Haha M, Le Saout G, Winnefeld F, Lothenbach B (2011) Influence of activator type on hydration kinetics, hydrate assemblage and microstructural development of alkali activated blast-furnace slags. Cem Concr Res 41(3):301–310. https://doi.org/10.1016/j.cemconres.2010.11.016

Abdalqader AF, Jin F, Al-Tabbaa A (2016) Development of greener alkali-activated cement: utilisation of sodium carbonate for activating slag and fly ash mixtures. J Clean Prod 113:66–75. https://doi.org/10.1016/j.jclepro.2015.12.010

Yu P, Kirkpatrick RJ, Poe B, McMillan PF, Cong X (2004) Structure of calcium silicate hydrate (C-S-H): near-, mid-, and far-infrared spectroscopy. J Am Ceram Soc 82:742–748. https://doi.org/10.1111/j.1151-2916.1999.tb01826.x

García-Lodeiro I, Fernández-Jiménez A, Blanco MT, Palomo A (2007) FTIR study of the sol–gel synthesis of cementitious gels: C-S–H and N–A–S–H. J Sol-Gel Sci Technol 45:63–72. https://doi.org/10.1007/s10971-007-1643-6

Yuan B, Yu QL, Brouwers HJH (2017) Time-dependent characterization of Na2CO3 activated slag. Cem Concr Compos 84:188–197. https://doi.org/10.1016/j.cemconcomp.2017.09.005

Sitarz M, Handke M, Mozgawa W (2000) Identification of silicooxygen rings in SiO2 based on IR spectra. Spectroch Acta Part A Mol Biomol Spectr 56(9):1819–1823. https://doi.org/10.1016/S1386-1425(00)00241-9

Sitarz M, Handke M, Mozgawa W, Galuskin E, Galuskina I (2000) The non-ring cations influence on silicooxygen ring vibrations. J Mol Struct 555(1–3):357–362. https://doi.org/10.1016/S0022-2860(00)00621-9

García-Lodeiro I, Fernández-Jiménez A, Blanco MT, Palomo A (2008) FTIR study of the sol-gel synthesis of cementitious gels: C-S-H and N-A-S-H. J Sol-Gel Sci Technol 45:63–72. https://doi.org/10.1007/s10971-007-1643-6

Lecomte I, Henrist C, Liégeois M, Maseri F, Rulmont A, Cloots R (2006) (Micro)-structural comparison between geopolymers, alkali-activated slag cement and Portland cement. J Eur Ceram Soc 26:3789–3797. https://doi.org/10.1016/j.jeurceramsoc.2005.12.021

GarcíaLodeiro I, Macphee DE, Palomo A, Fernández-Jiménez A (2009) Effect of alkalis on fresh C–S–H gels. FTIR analysis. Cem Concr Res 39(3):147–153. https://doi.org/10.1016/j.cemconres.2009.01.003

Bernal SA, Mejía De Gutierrez R, Provis JL, Rose V (2010) Effect of silicate modulus and metakaolin incorporation on the carbonation of alkali silicate-activated slags. Cem Concr Res 40:898–907. https://doi.org/10.1016/j.cemconres.2010.02.003

Zhang YJ, Zhao YL, Li HH, Xu DL (2008) Structure characterization of hydration products generated by alkaline activation of granulated blast furnace slag. J Mater Sci 43:7141–7147. https://doi.org/10.1007/s10853-008-3028-9

Gebregziabiher BS, Thomas R, Peethamparan S (2015) Very early-age reaction kinetics and microstructural development in alkali-activated slag. Cem Concr Compos 55:91–102. https://doi.org/10.1016/j.cemconcomp.2014.09.001

Yusuf MO, Johari MAM, Ahmad ZA, Maslehuddin M (2014) Effects of addition of Al(OH)3 on the strength of alkaline activated ground blast furnace slag-ultrafine palm oil fuel ash (AAGU) based binder. Constr Build Mater 50:361–367. https://doi.org/10.1016/j.conbuildmat.2013.09.054

Shi Z, Shi C, Wan S, Li N, Zhang Z (2018) Effect of alkali dosage and silicate modulus on carbonation of alkali-activated slag mortars. Cem Concr Res 113:55–64. https://doi.org/10.1016/j.cemconres.2018.07.005

Davidovits J, Davidovits M, Davidovits N (1994) Process for obtaining a geopolymeric alumino-silicate and products thus obtained, 5342595

He P, Wang M, Fu S, Jia D, Yan S, Yuan J, Xu J, Wang P, Zhou Y (2016) Effects of Si/Al ratio on the structure and properties of metakaolin based geopolymer. Ceram Int 42:14416–14422. https://doi.org/10.1016/j.ceramint.2016.06.033

Lee B, Kim G, Kim R, Cho B, Lee S, Chon CM (2017) Strength development properties of geopolymer paste and mortar with respect to amorphous Si/Al ratio of fly ash. Constr Build Mater 151:512–519. https://doi.org/10.1016/j.conbuildmat.2017.06.078

Çetintaş R, Soyer-Uzun S (2018) Relations between structural characteristics and compressive strength in volcanic ash based one–part geopolymer systems. J Build Eng 20:130–136. https://doi.org/10.1016/j.jobe.2018.07.011

Acknowledgements

This research was conducted at the Construction Materials Laboratory of Istanbul Bilgi University. The authors would like to acknowledge the financial support from the Istanbul Bilgi University Research Fund (Project Code: 2019.02.004). The authors would like to acknowledge the AKCANSA Cement Company for supplying slag and cement. Moreover, we would like to thank the METU Central Laboratory and Yildiz Technical University Central Laboratory for the XRD and SEM analyses.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Akturk, B., Ayhan, B.U. Alkali-activated basalt powder/slag systems: compressive strength and microstructural characterization. Mater Struct 56, 81 (2023). https://doi.org/10.1617/s11527-023-02165-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02165-1