Abstract

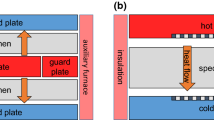

The search for sustainability achievement in the building sector led to the use of crop-based insulation materials. Among these, raw products like plant straws bales can present elementary representative volumes in the size order of several square centimeters. Fibers orientation may play an important role on material thermal behavior. Measuring their thermal conductivities with standard steady-state equipment can thus lead to some inaccuracies due to the necessity of resetting lower thickness samples. This paper presents a guarded hot plate apparatus designed to test high thickness samples, up to 40 cm, with an accuracy of 2 %. The different parts of the machine are described in details along with design process and challenges encountered. Temperature and heat flux measurements in the device represent critical design stages where optimal accuracy is needed in order to optimize the resulting global error. Regarding this, necessary numerical and experimental analyzes were conducted emphasizing on intrinsic systematic error assessment. To complete the study, some validations tests are performed on a reference material and other widely-spread polystyrene slabs. These tests take into account the optimal computation parameters resulting from the numerical analysis and the apparatus proved to be in accordance with accuracy requirements.

Similar content being viewed by others

References

Cripps A, Handyside R, Dewar L, Fovargue J (2004) Crops in construction handbook. CIRIA, London

Yates T (2006) The use of non-food crops in the UK construction industry. J Sci Food Agric 86(12):1790–1796

Jones B (2002) Building with straw bales. Green Books, Totnes

King B (2006) Design of straw bale buildings. Green Building Press, San Rafael

Wihan J (2007) Humidity in straw bale walls and its effect on the decomposition of straw. PhD Thesis, University of East London School of Computing and Technology

De Ponte F, Klarsfeld S (2002) Conductivité thermique des isolants. Techniques de l’ingénieur. http://www.techniques-ingenieur.fr/base-documentaire/mesures-analyses-th1/methodes-thermiques-d-analyse-42384210/conductivite-thermique-des-isolants-r2930. Accessed 4 April 2012

Munch-Andersen J (2004) Halmhuse: Udformning og materialeegenskaber. Statens Byggeforskningsinstitut, SBI, Horsholm

FASBA (2009) Thermal performance: straw bale building research development. FASBA, Verden

McCabe J (1998) The thermal insulating value of straw bale for construction. In: National passive conference, Albuquerque

Goodhew S, Griffiths R (2004) Analysis of thermal-probe measurements using an iterative method to give sample conductivity and diffusivity data. Appl Energy 77(2):205–223

Shea A, Wall K, Walker P (2012) Evaluation of the thermal performance of an innovative prefabricated natural plant fibre building system. Build Serv Eng Res Technol 34(4):1–12

Beck A, Heinemann U, Reidinger M, Fricke J (2004) Thermal transport in straw insulation. J Therm Envel Build Sci 27(3):227–234

Pruteanu M (2010) Investigations regarding the thermal conductivity of straw. Bull Polytech Inst Jassy 56(60):9–16

Ashour T (2003) The use of renewable agricultural by-products as building materials. PhD Thesis, Benha University

International Standard, ISO 8302 (1991) Thermal insulation—determination of steady-state thermal resistance and related properties

Leong WH, Hollands K, Brunger A (1998) On a physically-realizable benchmark problem in internal natural convection. Int J Heat Mass Transf 41(23):3817–3828

Reid D (2005) Guarded hot plate apparatus design and construction for thermal conductivity measurements. PhD Thesis, Ryerson University

Zarr R, Healy W, Filliben J, Flynn D (2002) Design concepts for a new guarded hot plate apparatus for use over an extended temperature range. In: Insulation materials: testing and applications, vol 4. ASTM International, West Conshohocken

Leephakpreeda T (2012) Applications of thermoelectric modules on heat flow detection. ISA Trans 51(2):345–350

Klarsfeld S (2004) Isolation thermique à température ambiante. Techniques Ingénieur. http://www.techniques-ingenieur.fr/base-documentaire/energies-th4/echangeurs-de-chaleur-et-isolation-42376210/isolation-thermique-a-temperature-ambiante-proprietes-be9860. Accessed 10 Dec 2012

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dubois, S., Lebeau, F. Design, construction and validation of a guarded hot plate apparatus for thermal conductivity measurement of high thickness crop-based specimens. Mater Struct 48, 407–421 (2015). https://doi.org/10.1617/s11527-013-0192-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-013-0192-4