Abstract

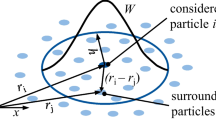

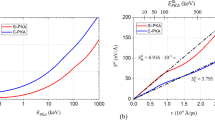

The cubic silicon carbide (3C-SiC) has broad application prospects due to its excellent properties. The modeling of damage in 3C-SiC due to contact loads is important yet challenging. In this paper, simulations based on peridynamics theory are proposed to model damage of 3C-SiC in indentation and scratching. In indentation, the pop-in phenomenon of load-depth curve and initiation and propagation of cracks are observed. During scratching, the specific cutting energy (energy consumed per unit volume of material removed) increases nonlinearly with the decrease of scratching depth. Initiation and propagation of radical cracks on both sides of the groove are found. In addition, for scratching with double indenters, the volume of material removal is more than twice that of scratching with an indenter when indenter interval is less than the threshold. This paper demonstrates that peridynamics is a powerful tool to investigate damage in indentation and scratching of brittle materials.

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

D.N. Talwar, J.C. Sherbondy, Thermal expansion coefficient of 3C–SiC. Appl. Phys. Lett. 67(22), 3301–3303 (1995)

H. Guo et al., Epitaxial growth and electrical performance of graphene/3C–SiC films by laser CVD. J. Alloys Compd. 826, 154198 (2020)

N. Biscay et al., Behavior of silicon carbide materials under dry to hydrothermal conditions. Nanomaterials 11(5), 1351 (2021)

P. Mélinon et al., Playing with carbon and silicon at the nanoscale. Nat. Mater. 6(7), 479–490 (2007)

M. Yoshida et al., Pressure-induced phase transition in SiC. Phys. Rev. B 48(14), 10587 (1993)

D. Tian et al., In situ investigation of nanometric cutting of 3C-SiC using scanning electron microscope. Int. J. Adv. Manuf. Technol. 115(7), 2299–2312 (2021)

S. Zhao, R. Flanagan, E.N. Hahn et al., Shock-induced amorphization in silicon carbide. Acta Mater. 158, 206–213 (2018)

A. Nawaz et al., Nanoscale elastic-plastic deformation and mechanical properties of 3C-SiC thin film using nanoindentation. Int. J. Appl. Ceram. Technol. 16(2), 706–717 (2019)

M. Alam et al., Finite element modeling of brittle and ductile modes in cutting of 3C-SiC. Crystals 11(11), 1286 (2021)

L. Zhao et al., Atomistic origin of brittle-to-ductile transition behavior of polycrystalline 3C–SiC in diamond cutting. Ceram. Int. 47(17), 23895–23904 (2021)

M. Mishra, I. Szlufarska, Possibility of high-pressure transformation during nanoindentation of SiC. Acta Mater. 57(20), 6156–6165 (2009)

S. Goel et al., Anisotropy of single-crystal 3C-SiC during nanometric cutting. Model. Simul. Mater. Sci. Eng. 21(6), 065004 (2013)

D. Liao et al., Analysis of elastic-plastic deformation law on 3C-SiC ceramic parts with different indenters by nanoindentation via molecular dynamics simulation. JOM 74, 2277–2286 (2022)

J.N. Reddy, Introduction to the Finite Element Method (McGraw-Hill Education, New York, 2019)

S. Ma, X. Zhang, X.M. Qiu, Comparison study of MPM and SPH in modeling hypervelocity impact problems. Int. J. Impact Eng. 36(2), 272–282 (2009)

L. Zhao et al., Depth-sensing ductile and brittle deformation in 3C-SiC under Berkovich nanoindentation. Mater. Des. 197, 109223 (2021)

Y. Liu et al., Smoothed particle hydrodynamics simulation and experimental analysis of SiC ceramic grinding mechanism. Ceram. Int. 44(11), 12194–12203 (2018)

N. Duan et al., Analysis of grit interference mechanisms for the double scratching of monocrystalline silicon carbide by coupling the FEM and SPH. Int. J. Mach. Tools Manuf. 120, 49–60 (2017)

V. Anicode, C. Diyaroglu, E. Madenci, Peridynamic modeling of damage due to multiple sand particle impacts in the presence of contact and friction, in AIAA Scitech 2020 Forum, 2020.

S.A. Silling, Reformulation of elasticity theory for discontinuities and long-range forces. J. Mech. Phys. Solids 48(1), 175–209 (2000)

M. Isiet, I. Mikovi, S. Mikovi, Review of peridynamic modelling of material failure and damage due to impact. Int. J. Impact Eng 147, 103740 (2021)

R.W. Macek, S.A. Silling, Peridynamics via finite element analysis. Finite Elem. Anal. Des. 43(15), 1169–1178 (2007)

S.A. Silling et al., Peridynamic states and constitutive modeling. J. Elast. 88(2), 151–184 (2007)

S.A. Silling, E. Askari, A meshfree method based on the peridynamic model of solid mechanics. Comput. Struct. 83(17–18), 1526–1535 (2005)

J.A. Mitchell, A nonlocal, ordinary, state-based plasticity model for peridynamics. No. SAND2011-3166 (Sandia National Laboratories (SNL), Albuquerque/Livermore, 2011).

N. Liu, D. Liu, Wu. Zhou, Peridynamic modelling of impact damage in three-point bending beam with offset notch. Appl. Math. Mech. 38(1), 99–110 (2017)

S. Niazi, Z. Chen, F. Bobaru, Crack nucleation in brittle and quasi-brittle materials: a peridynamic analysis. Theoret. Appl. Fract. Mech. 112, 102855 (2021)

O. Karpenko, S. Oterkus, E. Oterkus, Peridynamic analysis to investigate the influence of microstructure and porosity on fatigue crack propagation in additively manufactured Ti6Al4V. Eng. Fract. Mech. 261, 108212 (2022)

Y. Wu et al., A peridynamic model for dynamic fracture of layered engineered cementitious composites. Acta Mech. Solida Sin. 35, 661–671 (2022)

S. Shang et al., A bond-based peridynamic modeling of machining of unidirectional carbon fiber reinforced polymer material. Int. J. Adv. Manuf. Technol. 102(9), 4199–4211 (2019)

E. Postek, T. Sadowski, M. Boniecki, Impact of brittle composites: peridynamics modelling. Mater. Today: Proceedings 45, 4268–4274 (2021)

L. Wang, X. Sheng, J. Luo, A peridynamic frictional contact model for contact fatigue crack initiation and propagation. Eng. Fract. Mech. 264, 108338 (2022)

Z. Li et al., Nonlocal steady-state thermoelastic analysis of functionally graded materials by using peridynamic differential operator. Appl. Math. Model. 93, 294–313 (2021)

D. He, D. Huang, D. Jiang, Modeling and studies of fracture in functionally graded materials under thermal shock loading using peridynamics. Theoret. Appl. Fract. Mech. 111, 102852 (2021)

Y. Cao et al., Modeling the nanoindentation response of silicate glasses by peridynamic simulations. J. Am. Ceram. Soc. 104(7), 3531–3544 (2021)

S. Ebrahimi, D. Steigmann, K. Komvopoulos, Peridynamics analysis of the nanoscale friction and wear properties of amorphous carbon thin films. J. Mech. Mater. Struct. 10(5), 559–572 (2015)

A. Datye, H.-T. Lin, Energy analysis of spherical and Berkovich indentation contact damage in commercial polycrystalline silicon carbide. Ceram. Int. 43(1), 800–809 (2017)

Z. Qiu et al., Crack propagation and the material removal mechanism of glass–ceramics by the scratch test. J. Mech. Behav. Biomed. Mater. 64, 75–85 (2016)

L. Zhao et al., Amorphization-governed elasto-plastic deformation under nanoindentation in cubic (3C) silicon carbide. Ceram. Int. 46(8), 12470–12479 (2020)

Bo. Zhu, D. Zhao, H. Zhao, A study of deformation behavior and phase transformation in 4H-SiC during nanoindentation process via molecular dynamics simulation. Ceram. Int. 45(4), 5150–5157 (2019)

D. Huang, Lu. Guangda, P. Qiao, An improved peridynamic approach for quasi-static elastic deformation and brittle fracture analysis. Int. J. Mech. Sci. 94, 111–122 (2015)

M.L. Parks, et al., Peridigm users’ guide. Techincal Report SAND2012-7800 (Sandia National Laboratories (SNL), Albuquerque, 2012).

S. Nagappa, M. Zupan, C.A. Zorman, Mechanical characterization of chemical-vapor-deposited polycrystalline 3C silicon carbide thin films. Scr. Mater. 59(9), 995–998 (2008)

C.A. Klein, G.F. Cardinale, Young’s modulus and Poisson’s ratio of CVD diamond. Diam. Relat. Mater. 2(5–7), 918–923 (1993)

F. Bobaru, Hu. Wenke, The meaning, selection, and use of the peridynamic horizon and its relation to crack branching in brittle materials. Int. J. Fract. 176(2), 215–222 (2012)

F. Zhang et al., Friction behavior in nanoscratching of reaction bonded silicon carbide ceramic with Berkovich and sphere indenters. Tribol. Int. 97, 21–30 (2016)

Funding

This work is supported by Beijing Natural Science Foundation (Nos. L212025 and 3202024), NSAF (No. U2130108), National Natural Science Foundation of China (No. 51875405), Tribology Science Fund of State Key Laboratory of Tribology in Advanced Equipment (No. SKLTKF20B13), and Beijing Institute of Technology Research Fund Program for Young Scholars.

Author information

Authors and Affiliations

Contributions

YX contributed toward methodology, software, data curation, formal analysis, writing—original draft, and visualization. PZ contributed toward conceptualization, validation, resources, writing—review and editing, supervision, project administration, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, Y., Zhu, P. Peridynamic simulations of damage in indentation and scratching of 3C-SiC. Journal of Materials Research 37, 4381–4391 (2022). https://doi.org/10.1557/s43578-022-00812-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00812-x