Abstract

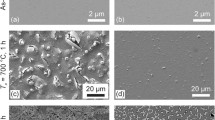

We present experimental results directed at understanding the growth and structure of metallic barrier layer and interconnect films. Numerical simulation results associated with this experimental work are presented in an accompanying paper in these proceedings. Here, thin films of Al, Ti, Cu and Ta have been grown by magnetron sputtering onto oxidized Si substrates. Using a specially-constructed substrate holder, the orientation of the substrate with respect to the growth direction was varied from horizontal to vertical. Films were grown at both low and high argon pressure; in the case of Ta, the cathode power was varied as well. The film structure and in particular the surface roughness was measured by X-ray reflectance and also by atomic force microscopy. We find that the surface roughness increases markedly with orientation angle in the case of Ta and Cu films, and in Ti films grown at high argon pressure. At low pressure, however, the Ti film surface roughness remains constant for all substrate orientations. No variation in roughness with either orientation angle or argon pressure was observed in the Al films. These results suggest that, under certain circumstances, shadowing effects and/or grain orientation (i.e., texture) competition during growth can give rise to lower density, more porous (and thus more rough) films, particularly at large orientation angles, as on sidewalls in sub-micron trenches.

Similar content being viewed by others

References

‘Thin Film Processes’, edited by J. L. Vossen and W. Kern, Academic Press, San Diego, CA, 1978, pp. 115-129

D. L. Windt, Computers in Physics, 12, 360–370 (1998)

D. G. Steams, J. Appl. Phys. 65, 491–506 (1989)

Note, however, that for thicker films, the amplitude of the oscillations are also reduced as a result of the finite instrumental angular resolution.

The rms surface roughness values determined by AFM are consistently less than those determined from XRR analysis. This discrepancy is due to the difference in spatial frequencies sampled by each technique. See, for example, D. L. Windt, W. K. Waskiewicz, and J. E. Griffith, App. Opt., 33, 2025–2031 (1994)

‘Thin Film Processes’, edited by J. L. Vossen and W. Kern, Academic Press, San Diego, CA, 1978, pp. 101-102.

J. A. Thornton, J. Vac. Sci. Technol, 11, 666–670 (1974)

R. A. Roy and R. Messier, J. Vac. Sci. Technol. A, 2, 312–315 (1984)

H. Windishcmann, J. Vac. Sci. Technol. A, 9, 2431–2436 (1991)

F. M. D’Heurle, Metall. Transactions, 1, 725–732 (1970)

G. S. Bales and A. Zangwill, J. Vac. Sci. Technol. A., 9 145–149 (1991)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Windt, D.L., Torre, J.D., Gilmer, G.H. et al. Growth and Structure of Metallic Barrie Laye and Interconnect Films I: Exeriments. MRS Online Proceedings Library 564, 307–312 (1999). https://doi.org/10.1557/PROC-564-307

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-564-307