Abstract

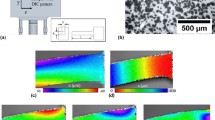

The stress and hence strain fields in a cantilever deforming as per power-law creep vary across the length and thickness of the sample, which allow obtaining multiple stress–strain pairs from a single test. Here, a high-throughput method is described to quantify the primary-cum-steady-state creep response of materials by testing a single cantilever sample in bending and mapping strain fields using digital image correlation. The method is based on the existence of stress invariant points in a cantilever, where the value of stress does not change during creep. It is demonstrated that strain evolution throughout primary and steady-state stages at these points is identical to the creep response obtained under uniaxial tests. Furthermore, the gained insights were exploited to obtain various parameters of a power-law type primary-cum-steady-state creep equation by testing only one cantilever sample. The developed method allows obtaining uniaxial creep curves at multiple stresses by testing a single cantilever, thereby reducing the time and number of samples required to understand the creep behavior of a material. The method has been validated by performing bending tests on Al and comparing the results with those of corresponding uniaxial tests.

Similar content being viewed by others

References

S.I.A. Jalali, P. Kumar, and V. Jayaram: Creep of metallic materials in bending. JOM 71, 3563 (2019).

S.I.A. Jalali, P. Kumar, and V. Jayaram: “ High Throughput Determination of Creep Parameters Using Cantilever Bending: Part I - Steady-State ”. J. Mater. Res. (2020). (In review).

S. I. A. Jalali: Evaluation of Power-Law Creep in Bending, PhD Thesis, Indian Institute of Science, Bangalore, India (2020).

E. Hosseini, V. Kalyanasundaram, X. Li, and S.R. Holdsworth: Effect of prior deformation on the subsequent creep and anelastic recovery behaviour of an advanced martensitic steel. Mater. Sci. Eng., A 717, 68 (2018).

Z. Kowalewski: Creep Structure (Springer Berlin Heidelberg, Berlin, Heidelberg, 1991); pp. 115–122.

E.P. Popov: Bending of beams with creep. J. Appl. Phys. 20, 251 (1949).

G.W. Hollenberg, G.R. Terwilliger, and R.S. Gordon: Calculation of stresses and strains in four-point bending creep tests. J. Am. Ceram. Soc. 54, 196 (1971).

F. Zhuang, S. Tu, G. Xie, S. Shao, and L. Cao: Materials Fabrication, Vol. 6B (ASME 2018 Pressure Vessels and Piping Conference, was held in Prague, Czech Republic, American Society of Mechanical Engineers, 2018); pp. PVP2018–84135, V06BT06A062.

J.T. Boyle and J. Spence: Stress Analysis for Creep (Butterworth-Heinemann, London 1983).

G.H. MacCullough: An experimental and analytical investigation of creep in bending. J. Appl. Mech. 55, 9 (1933).

H.J. Tapsell and A.E. Johnson: An investigation of the nature of creep under stresses produced by pure flexure. Mon. J. Inst. Met. 58, 387 (1935).

D.A. Woodford: Measurement and interpretation of the stress dependence of creep at low stresses. Mater. Sci. Eng. 4, 146 (1969).

M.E. Kassner: Fundamentals of Creep in Metals and Alloys (Butterworth-Heinemann, Elsevier, Boston 2015).

Acknowledgments

Authors would like to thank Aeronautical Research and Development Board, India (ARDB 0242), India and Ministry of Human Resource Development and Ministry of Power, Government of India (IMPRINT 0009), for financially supporting this work.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Afzal Jalali, S.I., Kumar, P. & Jayaram, V. High Throughput Determination of Creep Parameters Using Cantilever Bending: Part II - Primary and Steady-State through Uniaxial Equivalency. Journal of Materials Research 35, 362–371 (2020). https://doi.org/10.1557/jmr.2020.37

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.37