Abstract

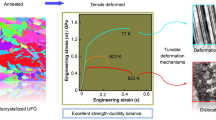

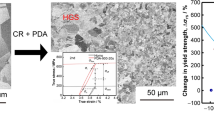

Nanocrystalline (NC) and ultrafine-grained (UFG) CoCrCuFeNi high-entropy alloy (HEA) with grain size ranging between 59 and 386 nm was produced via powder metallurgy and heat treatment. The as-sintered HEA exhibited two face-centered cubic (FCC) phases (CoCrFeNi-rich and Cu-rich phases) and a small grain size (59 nm), whereas the alloy after heat treatment at 1000 °C exhibited a CoCuFeNi-rich phase with FCC structure and relatively larger grain size (386 nm). Moreover, the yield strength decreased from 1930 to 883 MPa, and plastic strain to failure increased by 8–32%. In terms of microstructural evolution, grain boundary strengthening coupled with lattice distortion was the dominant strengthening mechanism for NC HEAs. Furthermore, the coefficient for boundary strengthening was higher in the HEAs than in the corresponding pure elemental metals with FCC structure, possibly because of significant lattice distortion. The UFG HEAs exhibited high strength and good ductility because of the activation of dislocation.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

B. Gwalani, V. Soni, D. Choudhuri, M. Lee, J.Y. Hwang, S.J. Nam, H. Ryu, S.H. Hong, and R. Banerjee: Stability of ordered L12 and B2 precipitates in face centered cubic based high entropy alloys—Al0.3CoFeCrNi and Al0.3CuFeCrNi2. Scr. Mater. 123, 130 (2016).

M.H. Tsai, H. Yuan, G. Cheng, W. Xu, K.Y. Tsai, C.W. Tsai, W.W. Jian, C.C. Juan, W.J. Shen, M.H. Chuang, J.W. Yeh, and Y.T. Zhu: Morphology, structure and composition of precipitates in Al0.3CoCrCu0.5FeNi high-entropy alloy. Intermetallics 32, 329 (2013).

X.F. Wang, Y. Zhang, Y. Qiao, and G.L. Chen: Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys. Intermetallics 15, 357 (2007).

C-J. Tong, Y-L. Chen, J-W. Yeh, S-J. Lin, S-K. Chen, T-T. Shun, C-H. Tsau, and S-Y. Chang: Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall. Mater. Trans. A 36, 881 (2005).

A. Kumar, P. Dhekne, A.K. Swarnakar, and M.K. Chopkar: Analysis of Si addition on phase formation in AlCoCrCuFeNiSix high entropy alloys. Mater. Lett. 188, 73 (2017).

T. Borkar, B. Gwalani, D. Choudhuri, C.V. Mikler, C.J. Yannetta, X. Chen, R.V. Ramanujan, M.J. Styles, M.A. Gibson, and R. Banerjee: A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 1.5) complex concentrated alloys: Microstructure, microhardness, and magnetic properties. Acta Mater. 116, 63 (2016).

H. Jiang, K. Han, D. Qiao, Y. Lu, Z. Cao, and T. Li: Effects of Ta addition on the microstructures and mechanical properties of CoCrFeNi high entropy alloy. Mater. Chem. Phys. 210, 43 (2018).

W.H. Liu, T. Yang, and C.T. Liu: Precipitation hardening in CoCrFeNi-based high entropy alloys. Mater. Chem. Phys. 210, 2 (2018).

C.C. Koch: Nanocrystalline high-entropy alloys. J. Mater. Res. 32, 3435 (2017).

Y. Zou, J.M. Wheeler, H. Ma, P. Okle, and R. Spolenak: Nanocrystalline high-entropy alloys: A new paradigm in high-temperature strength and stability. Nano Lett. 17, 1569 (2017).

H. Shahmir, J. He, Z. Lu, M. Kawasaki, and T.G. Langdon: Effect of annealing on mechanical properties of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Mater. Sci. Eng., A 676, 294 (2016).

P.F. Yu, H. Cheng, L.J. Zhang, H. Zhang, Q. Jing, M.Z. Ma, P.K. Liaw, G. Li, and R.P. Liu: Effects of high pressure torsion on microstructures and properties of an Al0.1CoCrFeNi high-entropy alloy. Mater. Sci. Eng., A 655, 283 (2016).

S. Nam, M.J. Kim, J.Y. Hwang, and H. Choi: Strengthening of Al0.15CoCrCuFeNiTix–C (x = 0, 1, 2) high-entropy alloys by grain refinement and using nanoscale carbides via powder metallurgical route. J. Alloys Compd. 762, 29 (2018).

R.S. Ganji, P. Sai Karthik, K. Bhanu Sankara Rao, and K.V. Rajulapati: Strengthening mechanisms in equiatomic ultrafine grained AlCoCrCuFeNi high-entropy alloy studied by micro- and nanoindentation methods. Acta Mater. 125, 58 (2017).

D-H. Lee, I-C. Choi, M-Y. Seok, J. He, Z. Lu, J-Y. Suh, M. Kawasaki, T.G. Langdon, and J. Jang: Nanomechanical behavior and structural stability of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. J. Mater. Res. 30, 2804 (2015).

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, and A. Hohenwarter: Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 96, 258 (2015).

H. Shahmir, T. Mousavi, J. He, Z. Lu, M. Kawasaki, and T.G. Langdon: Microstructure and properties of a CoCrFeNiMn high-entropy alloy processed by equal-channel angular pressing. Mater. Sci. Eng., A 705, 411 (2017).

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Z. Fu: Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics 56, 24 (2014).

W. Chen, Z. Fu, S. Fang, H. Xiao, and D. Zhu: Alloying behavior, microstructure and mechanical properties in a FeNiCrCo0.3Al0.7 high entropy alloy. Mater. Des. 51, 854 (2013).

H.J. Fecht, E. Hellstern, Z. Fu, and W.L. Johnson: Nanocrystalline metals prepared by high-energy ball milling. Metall. Trans. A 21, 2333 (1990).

Z. Fu, W. Chen, H. Wen, D. Zhang, Z. Chen, B. Zheng, Y. Zhou, and E.J. Lavernia: Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 107, 59 (2016).

C.C. Koch, D.G. Morris, K. Lu, and A. Inoue: Ductility of nanostructured materials. MRS Bull. 24, 54 (1999).

H. Van Swygenhoven and J.R. Weertman: Deformation in nanocrystalline metals. Mater. Today 9, 24 (2006).

S.J. Sun, Y.Z. Tian, H.R. Lin, X.G. Dong, Y.H. Wang, Z.J. Zhang, and Z.F. Zhang: Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure. Mater. Des. 133, 122 (2017).

E. Ma and T. Zhu: Towards strength—ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today 20, 323 (2017).

X. Wu, F. Yuan, M. Yang, P. Jiang, C. Zhang, L. Chen, Y. Wei, and E. Ma: Nanodomained nickel unite nanocrystal strength with coarse-grain ductility. Sci. Rep. 5, 11728 (2015).

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan: Metastable high-entropy dual-phase alloys overcome the strength—ductility trade-off. Nature 534, 227 (2016).

C. Suryanarayana: Mechanical alloying and milling mechanical engineering. Prog. Mater. Sci. 46, 1 (2001).

X. Yang and Y. Zhang: Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132, 233 (2012).

S. Guo, C. Ng, J. Lu, and C.T. Liu: Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 109, 103505 (2011).

F.R. Boer: Cohesion in Metals: Transition Metal Alloys (North-Holland, Amsterdam, 1988).

H.F. Sheng, M. Gong, and L.M. Peng: Microstructural characterization and mechanical properties of an Al0.5CoCrFeCuNi high-entropy alloy in as-cast and heat-treated/quenched conditions. Mater. Sci. Eng., A 567, 14 (2013).

T. Guo, J. Li, J. Wang, Y. Wang, H. Kou, and S. Niu: Liquid-phase separation in undercooled CoCrCuFeNi high entropy alloy. Intermetallics 86, 110 (2017).

H. Mao, H-L. Chen, and Q. Chen: TCHEA1: A thermodynamic database not limited for “High entropy” alloys. J. Phase Equilib. Diffus. 38, 353 (2017).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu: Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 62, 105 (2014).

S. Fang, X. Xiao, L. Xia, W. Li, and Y. Dong: Relationship between the widths of supercooled liquid regions and bond parameters of Mg-based bulk metallic glasses. J. Non-Cryst. Solids 321, 120 (2003).

X.D. Xu, P. Liu, S. Guo, A. Hirata, T. Fujita, T.G. Nieh, C.T. Liu, and M.W. Chen: Nanoscale phase separation in a fcc-based CoCrCuFeNiAl0.5 high-entropy alloy. Acta Mater. 84, 145 (2015).

R. Sonkusare, P.D. Janani, N.P. Gurao, S. Sarkar, S. Sen, K.G. Pradeep, and K. Biswas: Phase equilibria in equiatomic CoCuFeMnNi high entropy alloy. Mater. Chem. Phys. 210, 269 (2018).

T.H. Courtney: Mechanical Behavior of Materials (Waveland Press, Long Grove, 2005).

Z. Fu, W. Chen, S. Fang, D. Zhang, H. Xiao, and D. Zhu: Alloying behavior and deformation twinning in a CoNiFeCrAl0.6Ti0.4 high entropy alloy processed by spark plasma sintering. J. Alloys Compd. 553, 316 (2013).

Z. Fu, W. Chen, H. Xiao, L. Zhou, D. Zhu, and S. Yang: Fabrication and properties of nanocrystalline Co0.5FeNiCrTi0.5 high entropy alloy by MA-SPS technique. Mater. Des. 44, 535 (2013).

S-H. Joo, H. Kato, M.J. Jang, J. Moon, E.B. Kim, S-J. Hong, and H.S. Kim: Structure and properties of ultrafine-grained CoCrFeMnNi high-entropy alloys produced by mechanical alloying and spark plasma sintering. J. Alloys Compd. 698, 591 (2017).

S.G. Ma, S.F. Zhang, J.W. Qiao, Z.H. Wang, M.C. Gao, Z.M. Jiao, H.J. Yang, and Y. Zhang: Superior high tensile elongation of a single-crystal CoCrFeNiAl0.3 high-entropy alloy by Bridgman solidification. Intermetallics 54, 104 (2014).

D. Wu, J. Zhang, J.C. Huang, H. Bei, and T.G. Nieh: Grain-boundary strengthening in nanocrystalline chromium and the Hall—Petch coefficient of body-centered cubic metals. Scr. Mater. 68, 118 (2013).

A.S. Khan, H. Zhang, and L. Takacs: Mechanical response and modeling of fully compacted nanocrystalline iron and copper. Int. J. Plast. 16, 1459 (2000).

J. Chen, L. Lu, and K. Lu: Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 54, 1913 (2006).

A. Godon, J. Creus, S. Cohendoz, E. Conforto, X. Feaugas, P. Girault, and C. Savall: Effects of grain orientation on the Hall—Petch relationship in electrodeposited nickel with nanocrystalline grains. Scr. Mater. 62, 403 (2010).

R. Armstrong, I. Codd, R.M. Douthwaite, and N.J. Petch: The plastic deformation of polycrystalline aggregates. Philos. Mag. 7, 45 (1962).

A.C. Arko and Y.H. Liu: The effect of atomic order on the Hall—Petch behavior in Ni3Fe. Metall. Trans. 2, 1875 (1971).

D.B. Williams and C.B. Carter: The Transmission Electron Microscope. Transmission Electron Microscopy (Springer, New York, 1996).

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, and E.P. George: Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 118, 152 (2016).

J. Liu, C. Chen, Y. Xu, S. Wu, G. Wang, H. Wang, Y. Fang, and L. Meng: Deformation twinning behaviors of the low stacking fault energy high-entropy alloy: An in situ TEM study. Scr. Mater. 137, 9 (2017).

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E.P. George: The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 61, 5743 (2013).

S.W. Wu, G. Wang, J. Yi, Y.D. Jia, I. Hussain, Q.J. Zhai, and P.K. Liaw: Strong grain-size effect on deformation twinning of an Al0.1CoCrFeNi high-entropy alloy. Mater. Res. Lett. 5, 276 (2017).

Acknowledgment

This study was supported by the National Research Foundation (NRF) of Korea and funded by Ministry of Science, ICT (MSIT; 2013K1A4A3055679, 2015R1D1A1A01060718, 2015R1A5A7037615, 2016M2B2A9A02943809, and 2017M1A3A3A02015639).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Nam, S., Hwang, J.Y., Jeon, J. et al. Deformation behavior of nanocrystalline and ultrafine-grained CoCrCuFeNi high-entropy alloys. Journal of Materials Research 34, 720–731 (2019). https://doi.org/10.1557/jmr.2018.477

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.477