Abstract

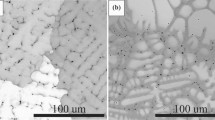

The design and the processing of a new class of titanium boride (TiB)-based bulk cermets containing a metallic phase (β-Ti phase) for toughening is presented. The general approach is rapid reaction and densification, using starting powders of Ti, TiB2, Fe, and Mo, by electric-field-activated sintering. The cermets consist of two-phase microstructures in which the boride phase formed as a networked structure of TiB whiskers that were created in situ upon the reaction between the powders. Hardness, flexural strength, and fracture toughness measurements of these materials revealed that they possess an interesting set of properties up to: hardness values of 1090 kg/mm2, flexural strength values of 953 MPa, and fracture toughness values of 18 MPa m1/2. A remarkable finding is that although the metallic phase fractured by microscopic cleavage, the cermets showed good fracture toughness values. The present study not only illustrates the process details and microstructure leading to these properties but also provides a broad powder metallurgical approach to design and synthesize cermets that may yield further improved properties.

Similar content being viewed by others

References

H.E. Exner: Physical and chemical nature of cemented carbides. Int. Met. Rev. 24, 149 (1979).

P. Ettmayer: Hardmetals and cermets. Annu. Rev. Mater. Sci. 19, 145 (1989).

D. Moskowitz and J. Humenik: TiC-based cermets for cutting applications. Mod. Dev. Powder Metall. 14, 307 (1985).

I.W.M. Brown and W.R. Owers: Fabrication, microstructure and properties of Fe–TiC ceramic–metal composites. Curr. Appl. Phys. 4, 171 (2004).

R. Subramanian and J.H. Schneibel: FeAl–TiC and FeAl–WC composites—Melt infiltration processing, microstructure and mechanical properties. Mater. Sci. Eng., A 244, 103 (1998).

S.Y. Zhang: Titanium carbonitride-based cermets: Processes and properties. Mater. Sci. Eng., A 163, 141 (1993).

J. Gurland: New scientific approaches to development of tool materials. Int. Met. Rev. 33, 151 (1988).

S.L. Sigl and H.F. Fischmeister: On the fracture toughness of cemented carbides. Acta Metall. 36, 887 (1988).

K.S. Ravichandran: Fracture toughness of two-phase WC-Co cermets. Acta Metall. Mater. 42, 143 (1994).

M. Humenik, Jr. and N.M. Parikh: Cermets: I, fundamental concepts related to micro-structure and physical properties of cermet systems. J. Am. Ceram. Soc. 39, 60 (1956).

N.M. Parikh and M. Humenik, Jr.: Cermets: II, wettability and microstructure studies in liquid-phase sintering. J. Am. Ceram. Soc. 40, 315 (1957).

S. Madtha, C. Lee, and K.S. Ravi Chandran: Physical and mechanical properties of nanostructured titanium boride (TiB) ceramic. J. Am. Ceram. Soc. 91, 1319–1321 (2008).

R.R. Atri, K.S. Ravichandran, and S.K. Jha: Elastic properties of in situ processed Ti–TiB composites measured by impulse excitation of vibration. Mater. Sci. Eng., A 271, 150 (1999).

K.B. Panda and K.S. Ravi Chandran: First principles determination of elastic constants and chemical bonding of titanium boride (TiB) on the basis of density functional theory. Acta Mater. 54, 1641 (2006).

S. Nakane, Y. Takano, M. Yoshinaka, K. Hirota, and O. Yamaguchi: Fabrication and mechanical properties of titanium boride ceramics. J. Am. Ceram. Soc. 82, 1627 (1999).

S.S. Sahay, K.S. Ravichandran, and R. Atri: Evolution of microstructure and phases in in situ processed Ti–TiB composites containing high volume fractions of TiB whiskers. J. Mater. Res. 14, 4214 (1999).

S. Madtha and K.S. Ravi Chandran: Reactive-sinter-processing and attractive mechanical properties of bulk and nanostructured titanium boride. J. Am. Ceram. Soc. 95, 117 (2012).

Titanium–Boron System: ASM Handbook: Alloy Phase Diagrams, Vol. 3 (ASM International, Materials Park, Ohio, 1992); p. 440.

H. Conrad: Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 26, 123 (1981).

J. Du and K.S. Ravi Chandran: Formation of bulk titanium boride (TiB) nano‐ceramic with Fe–Mo addition by electric-field-activated-sintering. J. Am. Ceram. Soc. 100, 5450 (2017).

V. Jindal and K.S. Ravi Chandran: Thermodynamic Assessment of Ti–B–Fe–Mo Quaternary System (Department of Metallurgical Engineering, University of Utah, Salt Lake City, 2018). (unpublished research).

ASTM International: ASTM C1161-13 Standard test method for flexural strength of advanced ceramics at ambient temperature. ASTM Stand. B. C. 1 (2013); pp. 1–19.

ASTM International: ASTM C1421-10 Standard test methods for determination of fracture toughness of advanced ceramics at ambient temperature. ASTM Stand. B.I. 1 (2011).

K. Panda and K.S. Ravi Chandran: Synthesis of ductile Ti–TiB composites with β-Ti alloy matrix. Metall. Mater. Trans. A 34, 1371 (2003).

J.D. Cotton, R.D. Briggs, R.R. Boyer, S. Tamirisakandala, P. Russo, N. Shchetnikov, and J.C. Fanning: State of the art in beta titanium alloys for airframe applications. JOM 67, 1281 (2015).

J. Du and K.S. Ravi Chandran: CALPHAD-guided alloy design and processing for high strength and high toughness in titanium boride (TiB) nanoceramic system. Acta Mater. (2018). (submitted to).

J. Du and K.S. Ravi Chandran: Department of Metallurgical Engineering, University of Utah, Salt Lake City, Utah (unpublished research).

K.S. Ravichandran: A survey of toughness in ductile phase composites. Scr. Metall. Mater. 26, 1389 (1992).

M.A. Przystupa and T.H. Courtney: Fracture in equiaxed two phase alloys: Part II. Fracture in alloys with isolated plastic particles. Metall. Trans. A 13, 881 (1982).

B.D. Flinn, M. Rühle, and A.G. Evans: Toughening in composites of Al2O3 reinforced with Al. Acta Metall. 37, 3001 (1989).

J.L. Chermant and F. Osterstock: Fracture toughness and fracture of WC-Co composites. J. Mater. Sci. 11, 1939 (1976).

J.R. Pickens and J. Gurland: The fracture toughness of WCCo alloys measured on single-edge notched beam specimens precracked by electron discharge machining. Mater. Sci. Eng. 33, 135 (1978).

J.H. Schneibel, C.A. Carmichael, E.D. Specht, and R. Subramanian: Liquid-phase sintered iron aluminide-ceramic composites. Intermetallics 5, 61 (1997).

R. Subramanian, J.H. Schneibel, K.B. Alexander, and K.P. Plucknett: Iron aluminide-titanium carbide composites by pressureless melt infiltration—Microstructure and mechanical properties. Scr. Mater. 35, 583 (1996).

ACKNOWLEDGMENTS

The research, largely performed M.S. thesis research of the first author, was supported by the National Science Foundation, the program on Designing Materials to Revolutionize our Engineering Future (DMREF), through the grant CMMI-1435758. The assistance provided by Dr. Tony Sanders, Dr. Mark Koopman, Somnaang Rou, Ahmed Degnah, and Richard Laroche is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Lark, A., Du, J. & Chandran, K.R. Material design and processing of a new class of titanium boride cermets with tough metallic phases and mechanical properties. Journal of Materials Research 33, 4296–4306 (2018). https://doi.org/10.1557/jmr.2018.368

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.368