Abstract

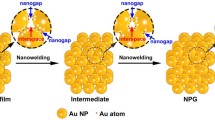

In this study, Au-based nanoglasses in the form of thin films deposited by magnetron sputtering are comparatively dealloyed. The films have either nanograined or nanocolumnar microstructure, depending on the working pressure of Ar in the sputtering chamber. Nanocolumnar thin films exhibit much higher dealloying rate reducing effectively the dealloying time with respect to nanograined and homogenous thin films. Electrocatalysis experiments indicate that the resulting nanoporous films are active for the methanol electrooxidation, with promising results in term of stability especially for the dealloyed nanocolumnar film.

Similar content being viewed by others

References

Y. Ding, Y.J. Kim, and J. Erlebacher: Nanoporous gold leaf: “Ancient technology ”/advanced material. Adv. Mater. 16, 1897 (2004).

R. Morrish, K. Dorame, and A.J. Muscat: Formation of nanoporous Au by dealloying AuCu thin films in HNO3. Scr. Mater. 64, 856 (2011).

J. Erlebacher, M.J. Aziz, A. Karma, N. Dimitrov, and K. Sieradzki: Evolution of nanoporosity in dealloying. Nature 410, 450 (2001).

I. McCue, E. Benn, B. Gaskey, and J. Erlebacher: Dealloying and dealloyed materials. Annu. Rev. Mater. Res. 46, 263 (2016).

F. Scaglione, F. Celegato, P. Rizzi, and L. Battezzati: A comparison of de-alloying crystalline and amorphous multicomponent Au alloys. Intermetallics 66, 82 (2015).

E.M. Paschalidou, F. Celegato, F. Scaglione, P. Rizzi, L. Battezzati, A. Gebert, S. Oswald, U. Wolff, L. Mihaylov, and T. Spassov: The mechanism of generating nanoporous Au by de-alloying amorphous alloys. Acta Mater. 119, 177 (2016).

Y. Xue, F. Scaglione, P. Rizzi, and L. Battezzati: Improving the chemical de-alloying of amorphous Au alloys. Corros. Sci. 127, 141 (2017).

H-J. Qiu, J.Q. Wang, P. Liu, Y. Wang, and M.W. Chen: Hierarchical nanoporous metal/metal-oxide composite by dealloying metallic glass for high-performance energy storage. Corros. Sci. 96, 196 (2015).

J. Erlebacher: Mechanism of coarsening and bubble formation in high-genus nanoporous metals. Phys. Rev. Lett. 106, 1 (2011).

G. Gupta, J.C. Thorp, N.A. Mara, A.M. Dattelbaum, A. Misra, and S.T. Picraux: Morphology and porosity of nanoporous Au thin films formed by dealloying of AuxSi1−x. J. Appl. Phys. 112, 1 (2012).

M.C. Dixon, T.A. Daniel, M. Hieda, D.M. Smilgies, M.H.W. Chan, and D.L. Allara: Preparation, structure, and optical properties of nanoporous gold thin films. Langmuir 23, 2414 (2007).

X. Li, H-J. Qiu, J.Q. Wang, and Y. Wang: Corrosion of ternary Mn–Cu–Au to nanoporous Au–Cu with widely tuned Au/Cu ratio for electrocatalyst. Corros. Sci. 106, 55 (2016).

S. Ding, Y. Liu, Y. Li, Z. Liu, S. Sohn, F.J. Walker, and J. Schroers: Combinatorial development of bulk metallic glasses. Nat. Mater. 13, 1 (2014).

H. Gleiter: The way from today’s materials to new kinds of amorphous solids: Nano-glasses. Proc. Indian Natl. Sci. Acad. 80, 55 (2014).

H. Gleiter: Nanoglasses: A new kind of noncrystalline material and the way to an age of new technologies?Small 12, 2225 (2016).

J.X. Fang, U. Vainio, W. Puff, R. Würschum, X.L. Wang, D. Wang, M. Ghafari, F. Jiang, J. Sun, H. Hahn, and H. Gleiter: Atomic structure and structural stability of Sc75Fe25 nanoglasses. Nano Lett. 12, 458 (2012).

J.Q. Wang, N. Chen, P. Liu, Z. Wang, D.V. Louzguine-Luzgin, M.W. Chen, and J.H. Perepezko: The ultrastable kinetic behavior of an Au-based nanoglass. Acta Mater. 79, 30 (2014).

R. Witte, T. Feng, J.X. Fang, A. Fischer, M. Ghafari, R. Kruk, R.A. Brand, D. Wang, H. Hahn, and H. Gleiter: Evidence for enhanced ferromagnetism in an iron-based nanoglass. Appl. Phys. Lett. 103, 73106 (2013).

X.L. Wang, F. Jiang, H. Hahn, J. Li, H. Gleiter, J. Sun, and J.X. Fang: Plasticity of a scandium-based nanoglass. Scr. Mater. 98, 40 (2015).

N. Chen, R. Frank, N. Asao, D.V. Louzguine-Luzgin, P. Sharma, J.Q. Wang, G.Q. Xie, Y. Ishikawa, N. Hatakeyama, Y.C. Lin, M. Esashi, Y. Yamamoto, and A. Inoue: Formation and properties of Au-based nanograined metallic glasses. Acta Mater. 59, 6433 (2011).

H. Guo, W. Zhang, C. Qin, J. Qiang, M. Chen, and A. Inoue: Glass-forming ability and properties of new Au-based glassy alloys with low Au concentrations. Mater. Trans. 50, 1290 (2009).

S. Xiao, F. Xiao, Y. Hu, S. Yuan, S. Wang, L. Qian, and Y. Liu: Hierarchical nanoporous gold–platinum with heterogeneous interfaces for methanol electrooxidation. Sci. Rep. 4, 4370 (2015).

J-Y. Suh, R. Dale Conner, C. Paul Kim, M.D. Demetriou, and W.L. Johnson: Correlation between fracture surface morphology and toughness in Zr-based bulk metallic glasses. J. Mater. Res. 25, 982 (2010).

Z. Sniadecki, D. Wang, Y. Ivanisenko, V.S.K. Chakravadhanula, C. Kübel, H. Hahn, and H. Gleiter: Nanoscale morphology of Ni50Ti45Cu5 nanoglass. Mater. Charact. 113, 26 (2016).

J.A. Thornton: High rate thick film growth. Annu. Rev. Mater. Sci. 7, 239 (1977).

J.A. Thornton: Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings. J. Vac. Sci. Technol. 11, 666 (1974).

K-Y. Chan and B-S. Teo: Atomic force microscopy (AFM) and X-ray diffraction (XRD) investigations of copper thin films prepared by dc magnetron sputtering technique. Microelectron. J. 37, 1064 (2006).

S. Kaciulis, A. Mezzi, G. Fiore, I. Ichim, L. Battezzati, and P. Rizzi: XPS study of gold-based metallic glass. Surf. Interface Anal. 42, 597 (2010).

M. Eisenbart, U.E. Klotz, R. Busch, and I. Gallino: A colourimetric and microstructural study of the tarnishing of gold-based bulk metallic glasses. Corros. Sci. 85, 258 (2014).

X. Lang, H. Guo, L. Chen, and A. Kudo: Novel nanoporous Au–Pd alloy with high catalytic activity and excellent electrochemical stability. J. Phys. Chem. C 114, 2600 (2010).

F. Scaglione, P. Rizzi, F. Celegato, and L. Battezzati: Synthesis of nanoporous gold by free corrosion of an amorphous precursor. J. Alloys Compd. 615, S142 (2014).

A. Gebert, K. Buchholz, A. Leonhard, K. Mummert, J. Eckert, and L. Schultz: Investigations on the electrochemical behaviour of Zr-based bulk metallic glasses. Mater. Sci. Eng., A 267, 294 (1999).

L. Mihaylov, L. Lyubenova, T. Gerdjikov, D. Nihtianova, and T. Spassov: Selective dissolution of amorphous Zr–Cu–Ni–Al alloys. Corros. Sci. 94, 350 (2015).

L. Mihailov, M. Redzheb, and T. Spassov: Selective dissolution of amorphous and nanocrystalline Zr2Ni. Corros. Sci. 74, 308 (2013).

E.M. Paschalidou, F. Scaglione, A. Gebert, S. Oswald, P. Rizzi, and L. Battezzati: Partially and fully de-alloyed glassy ribbons based on Au: Application in methanol electro-oxidation studies. J. Alloys Compd. 667, 302 (2016).

T. Fujita, P. Guan, K. McKenna, X. Lang, A. Hirata, L. Zhang, T. Tokunaga, S. Arai, Y. Yamamoto, N. Tanaka, Y. Ishikawa, N. Asao, Y. Yamamoto, J. Erlebacher, and M. Chen: Atomic origins of the high catalytic activity of nanoporous gold. Nat. Mater. 11, 775 (2012).

J. Zhang, P. Liu, H. Ma, and Y. Ding: Nanostructured porous gold for methanol electro-oxidation. J. Phys. Chem. C 111, 10382 (2007).

Z. Borkowska, A. Tymosiak-Zielinska, and G. Shul: Electrooxidation of methanol on polycrystalline and single crystal gold electrodes. Electrochim. Acta 49, 1209 (2004).

H. Heli, M. Jafarian, M.G. Mahjani, and F. Gobal: Electro-oxidation of methanol on copper in alkaline solution. Electrochim. Acta 49, 4999 (2004).

A. Khouchaf, D. Takky, and M. El Mahi Chbihi: Electrocatalytic oxidation of methanol on glassy carbon electrode modified by metal ions (copper and nickel) dispersed into polyaniline film. J. Mater. Sci. Chem. Eng. 4, 97 (2016).

S.S. Abd El Rehim, H.H. Hassan, M.A.M. Ibrahim, and M.A. Amin: Electrochemical behaviour of a silver electrode in NaOH solutions. Monatsh. Chem. 129, 1103 (1998).

Y. Wan, X. Wang, S. Liu, Y. Li, H. Sun, and Q. Wang: Effect of electrochemical factors on formation and reduction of silver oxides. Int. J. Electrochem. Sci. 8, 12837 (2013).

M-C. Jeong: Voltammetric studies on the palladium oxides in alkaline media. J. Electrochem. Soc. 140, 1986 (1993).

M. Grden, M. Lukaszewski, G. Jerkiewicz, and A. Czerwinski: Electrochemical behaviour of palladium electrode: Oxidation, electrodissolution and ionic adsorption. Electrochim. Acta 53, 7583 (2008).

K.A. Assiongbon and D. Roy: Electro-oxidation of methanol on gold in alkaline media: Adsorption characteristics of reaction intermediates studied using time resolved electro-chemical impedance and surface plasmon resonance techniques. Surf. Sci. 594, 99 (2005).

M. Graf, M. Haensch, J. Carstens, G. Wittstock, and J. Weissmüller: Electrocatalytic methanol oxidation with nanoporous gold: Microstructure and selectivity. Nanoscale 9, 17839 (2017).

ACKNOWLEDGMENTS

This work was supported by the funding scheme of the European Commission, Marie Curie Actions-Initial Training Networks (ITN) in the frame of the project VitriMetTech-Vitrified Metals Technologies and Applications in Devices and Chemistry, 607080 FP7-PEOPLE-2013-ITN. We would like to thank PX Services, La Chaux-de-Fonds (CH), for providing the material and the equipment necessary for the casting of the Au-based target.

Author information

Authors and Affiliations

Corresponding authors

Supplementary Material

43578_2018_33182661_MOESM1_ESM.docx

Supporting information: Microstructure and electrochemical properties of nanoporous Gold produced by dealloying Au-based thin film nano-glass (approximately 1.84 MB)

Rights and permissions

About this article

Cite this article

Denis, P., Fecht, HJ., Xue, Y. et al. Microstructure and electrochemical properties of nanoporous gold produced by dealloying Au-based thin film nanoglass. Journal of Materials Research 33, 2661–2670 (2018). https://doi.org/10.1557/jmr.2018.176

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.176