Abstract

Texture-engineered ceramics enable access to a vast array of novel texture-property relations leading to property values ranging between those of single crystals and isotropic bulk ceramics. Recently developed templated grain growth and magnetic alignment texturing methods yield high quality crystallographic texture, and thus significant advances in achievable texture-engineered properties in magnetic, piezoelectric, electronic, optical, thermoelectric, and structural ceramics. In this paper, we outline the fundamental basis for these texture-engineered properties and review recent contributions to the field of texture-engineered ceramics with an update on the properties of textured lead-free and lead-based piezoelectrics. We propose that further property improvements can be realized through development of processes that improve crystallographic alignment of the grain structure, create biaxial texture, and explore a wider array of crystallographic orientations. There is a critical need to model the physics of texture-engineered ceramics, and more comprehensively characterize texture, thus enabling testing of texture orientation-property relations and materials performance. We believe that in situ measurements of texture evolution can lead to a more fundamental and comprehensive understanding of the mechanisms of texture development.

Similar content being viewed by others

Change history

01 March 2018

An Erratum to this paper has been published: https://doi.org/10.1557/jmr.2018.31

References

G.W. Rathenau, J. Smit, and A.L. Stuyts: Ferromagnetic properties of hexagonal iron-oxide compounds with and without a preferred orientation. Z. Physik 133, 250 (1952).

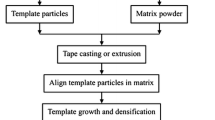

G.L. Messing, T. Trolier-McKinstry, E.M. Sabolsky, C. Duran, S. Kwon, B. Brahmaroutu, P. Park, H. Yilmaz, P.W. Rehrig, K.B. Eitel, E. Suvaci, M. Seabaugh, and K.S. Oh: Templated grain growth of textured piezoelectric ceramics. Crit. Rev. Solid State Mater. Sci. 29, 45 (2004).

S. Jin and J.E. Graebner: Processing and fabrication techniques for bulk high- Tc superconductors: A critical review. Mater. Sci. Eng., B 7, 243 (1991).

E. Guilmeau, H. Itahara, T. Tani, D. Chateigner, and D. Grebille: Quantitative texture analysis of grain-aligned (Ca2CoO3)0.62CoO2 ceramics processed by the reactive-templated grain growth method. J. Appl. Phys. 97, 064902 (2005).

X. Mao, S. Wang, S. Shimai, and J. Guo: Transparent polycrystalline alumina ceramics with orientated optical axes. J. Am. Ceram. Soc. 91, 3431 (2008).

H. Imamura, K. Hirao, M.E. Brito, M. Toriyama, and S. Kanzaki: Further improvement in mechanical properties of highly anisotropic silicon nitride ceramics. J. Am. Ceram. Soc. 83, 495 (2000).

G.E. Youngblood and R.S. Gordon: Texture-conductivity relationships in polycrystalline lithia-stabilized β″-alumina. Ceramurgia Intl. 4, 93 (1978).

A.H. Heuer, D.J. Sellers, and W.H. Rhodes: Hot-working of aluminum oxide: I. Primary recrystallization and texture. J. Am. Ceram. Soc. 52, 468 (1969).

A. Carman, E. Pereloma, and Y. Chen: Hot forging of a textured α-SiAlON ceramic. J. Am. Ceram. Soc. 89, 478 (2006).

J.J. Went, G.W. Rathenau, E.W. Gorter, and G.W. van Oosterhout: Hexagonal iron-oxide compounds as permanent-magnet materials. Phys. Rev. 86, 424 (1952).

A. Goyal, R. Feenstra, F.A. List, M. Paranthaman, D.F. Lee, D.M. Kroeger, D.B. Beach, J.S. Morrell, T.G. Chirayil, D.T. Verebelyi, X. Cui, E.D. Specht, D.K. Christen, and P.M. Martin: Using RABiTS to fabricate high-temperature superconducting wire. JOM 51, 19 (1999).

S. Jin, R.C. Sherwood, R.B. van Dover, T.H. Tiefel, and D.W. Johnson, Jr.: High TC superconductors-composite wire fabrication. Appl. Phys. Lett. 51, 203 (1987).

T. Tani: Texture engineering of electronic ceramics by the reactive-templated grain growth method. J. Ceram. Soc. Jpn. 114, 363 (2006).

H. Yilmaz, G.L. Messing, and S. Trolier-McKinstry: (Reactive) templated grain growth of textured sodium bismuth titanate (Na1/2Bi1/2TiO3–BaTiO3) ceramics–I. Processing. J. Electroceram. 11, 207 (2003).

Y. Sakka and T.S. Suzuki: Textured development of feeble magnetic ceramics by colloidal processing under high magnetic field. J. Ceram. Soc. Jpn. 113, 26 (2005).

M.M. Seabaugh, I.H. Kerscht, and G.L. Messing: Texture development by templated grain growth in liquid phase sintered α-alumina. J. Am. Ceram. Soc. 80, 1181 (1997).

T.S. Suzuki, T. Uchikoshi, and Y. Sakka: Control of texture in alumina by colloidal processing in a strong magnetic field. Sci. Technol. Adv. Mater. 7, 356 (2006).

J.L. Jones, B.J. Iverson, and K.J. Bowman: Texture and anisotropy of polycrystalline piezoelectrics. J. Am. Ceram. Soc. 90, 2297 (2007).

F.K. Lotgering: Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures-I. J. Inorg. Nucl. Chem. 9, 113 (1959).

K.H. Brosnan, G.L. Messing, R.J. Meyer, Jr., and M.D. Vaudin: Texture measurements in 〈001〉 fiber-oriented PMN–PT. J. Am. Ceram. Soc. 89, 1965 (2006).

W.A. Dollase: Correction for preferred orientation in powder diffractometry: Application of the March model. J. Appl. Crystallogr. 19, 267 (1986).

L.D. Landau, L.P. Pitaevskii, and E.M. Liftshitz: Electrodynamics of Continuous Media, 2nd ed., Vol. 8, Course of Theoretical Physics (Oxford University Press, Oxford, England, 2004).

R.C. Pullar: A review of the synthesis, properties and applications of hexaferrite ceramics. Prog. Mater. Sci. 57, 1191 (2012).

A.L. Stuijts, G.W. Rathenau, and G.H. Weber: Ferroxdure II and III, anisotropic permanent magnet materials. In Ferrites, J. Smit and H.P.J. Wijn, eds., Vol. 16 (Philips Technical Library, Eindhoven, Netherlands, 1959); p. 141.

Y. Chen, A. Daigle, T. Fitchorov, B. Hu, M. Geiler, and A. Geiler: Electronic tuning of magnetic permeability in Co2Z hexaferrite toward high frequency electromagnetic device miniaturization. Appl. Phys. Lett. 98, 202502 (2011).

G. Jian, F. Meng, D. Zhou, Q. Fu, Z. Du, and C. Yan: Fabrication of textured CoFe2O4 ceramics by novel RTGG method using rod-like α-FeOOH particles as templates. Mater. Chem. Phys. 162, 380 (2015).

P. Chang, L. He, D. Wei, and H. Wang: Textured z-type hexaferrite Ba3Co2Fe24O41, ceramics with high permeability by reactive templated grain growth method. J. Eur. Ceram. Soc. 36, 2519 (2016).

J.P. Rush, C.J. May-Miller, K.G.B. Palmer, N.A. Rutter, A.R. Dennis, Y-H. Shi, D.A. Cardwell, and J.H. Durrell: Transport Jc in bulk superconductors: A practical approach?. IEEE Trans. Appl. Supercond. 26, 6800904 (2016).

B. Raveau: Texturing of high- Tc superconductors. Supercond. Sci. Technol. 12, R115 (1999).

C. His, N. Chardon, R. Kuentzler, and S. Vilminot: Elaboration and characterization of YBa2Cu3O7−x thick tapes. J. Mater. Sci. 26, 4829 (1991).

D.M. Feldmann, T.G. Holesinger, R. Feenstra, and D.C. Larbalestier: A review of the influence of grain boundary geometry on the electromagnetic properties of polycrystalline YBa2Cu3O7−x films. J. Am. Ceram. Soc. 91, 1869 (2008).

A. Goyal, M.P. Paranthaman, and U. Schopp: The RABiTS approach: Using rolling-assisted biaxially textured substrates for high-performance YBCO superconductors. MRS Bull. 29, 552 (2004).

M.A. Susner, T.W. Daniels, M.D. Sumption, M.A. Rindfleisch, C.J. Thong, and E.W. Collings: Drawing induced texture and the evolution of superconductive properties with heat treatment time in powder-in-tube in situ processed MgB2 strands. Supercond. Sci. Tech. 25, 065002 (2012).

D. Dimos, P. Chaudhari, J. Mannhart, and F.K. LeGoues: Orientation dependence of grain-boundary critical currents in YBa2Cu3O7−δ bicrystals. Phys. Rev. Lett. 61, 219 (1988).

G-Z. Li, J-W. Li, and W-M. Yang: A combined powder melt and infiltration growth technique for fabricating nano-composited Y−Ba−Cu−O single-grain superconductor. Supercond. Sci. Technol. 28, 105002 (2015).

Y. Shi, J.H. Durrell, A.R. Dennis, K. Huang, D.K. Namburi, D. Zhou, and D.A. Cardwell: Multiple seeding for the growth of bulk GdBCO-Ag superconductors with single grain behaviour. Supercond. Sci. Technol. 30, 015003 (2017).

A. Bhargava, J. Schwartz, J.A. Alarco, and I.D.R. Mackinnon: Progress towards slip-casting YBa2Cu3O7−x monoliths. Mater. Lett. 30, 199 (1997).

L.C. Pathak: Fabrication and sintering characteristics of doctor blade YBCO-Ag tapes. Ceram. Int. 30, 417 (2004).

S.E. Dorris, M.T. Lanagan, D.M. Moffatt, H.J. Leu, C.A. Youngdahl, U. Balachandran, A. Cazzato, D.E. Bloomberg, and K.C. Goretta: Y2BaCuO5 as a substrate for YBa2Cu3Ox. Jpn. J. Appl. Phys. 28, 1415 (1989).

P.J. McGinn, W. Chen, N. Zhu, U. Balachandran, and M.T. Lanagan: Texture processing of extruded YBa2Cu3O6+ x wires by zone melting. Phys. C 165, 480 (1990).

G.S. Grader and D.W. Johnson, Jr.: Forming methods for high Tc superconductors. Thermochim. Acta 174, 239 (1991).

K.G. Frase, G.C. Farrington, and J.O. Thomas: Proton transport in the β/β″-aluminas. Annu. Rev. Mater. Sci. 14, 279 (1984).

J.V.L. Beckers, K.J. van der Bent, and S.W. de Leeuw: Ionic conduction in Na+-β-alumina studied by molecular dynamics simulation. Solid State Ionics 133, 217 (2000).

J.W. Fergus: Ion transport in sodium ion conducting solid electrolytes. Solid State Ionics 227, 102 (2012).

L.C. de Jonghe and J.B. Hall: Ion current concentration in grain boundaries of sodium beta alumina. Scr. Mater. 10, 285 (1976).

L.C. De Jonghe: Grain boundaries and ionic conduction in sodium beta alumina. J. Mater. Sci. 14, 33 (1979).

C.K. Kuo, A. Tan, and P.S. Nicholson: Solid state ionics impedance analysis as a tool for designing β″-alumina microstructures. Solid State Ionics 48, 315 (1991).

A. Kishimoto and K. Shimokawa: Preferential orientation dependent mechanical and electrical properties in Naβ-alumina ceramics. Key Eng. Mater. 301, 147 (2006).

A. Hooper: A study oft he electrical properties of single-crystal and polycrystalline β-alumina using complex plane analysis. J. Phys. D: Appl. Phys. 10, 1487 (1977).

A. Tan, C.K. Kuo, and P.S. Nicholson: Preparation and characterization of textured polycrystalline Na and K-β-aluminas. Solid State Ionics 42, 233 (1990).

A. Tan, C. Kun Kuo, and P.S. Nicholson: The influence of grain-boundaries on the conductivity and ion-exchange rate of β″-alumina polycrystalline isomorphs. Solid State Ionics 45, 137 (1991).

T. Ohta, M. Harata, and A. Imai: Preferred orientation on beta-alumina ceramics. Mater. Res. Bull. 11, 1343 (1976).

A.V. Virkar, G.R. Miller, and R.S. Gordon: Resistivity-microstructure relations in lithia-stabilized polycrystalline β″-alumina. J. Am. Ceram. Soc. 61, 250 (1978).

E. Butchereit, J. Schoonman, H.W. Zandbergen, C. Lutz-Elsner, M. Schreiber, and P. Wang: Microstructure-conductivity relationships in solid anisotropic ionically conducting materials. Mater. Res. Soc. Symp. Proc. 369, 433 (1995).

A.P. De Kroon, F. Gstrein, G.W. Schafer, and F. Aldinger: Ionic conductivity of dense K-β-alumina ceramics: Microstructural dependence and the influence of phase transformations. Solid State Ionics 133, 107 (2000).

H. Asaoka, R. Ogawa, H. Hayashi, and A. Kishimoto: Influence of kinds of aluminum source on the preferential orientation and properties of Naβ-alumina ceramics. J. Ceram. Soc. Jpn. 114, 719 (2006).

J.L. Shi, J.H. Gao, and Z.X. Lin: The relation between microstructure and ionic conductivity of hot-pressed β-Al2O3. J. Mater. Sci. 24, 1827 (1989).

K. Koganei, T. Oyama, M. Inada, N. Enomoto, and K. Hayashi: C-axis oriented β″-alumina ceramics with anisotropic ionic conductivity prepared by spark plasma sintering. Solid State Ionics 267, 22 (2014).

R. Subasri and H. Näfe: Texture in Na-β-Al2O3 due to microwave processing. Mater. Chem. Phys. 112, 16 (2008).

Y. Sakka, A. Honda, T.S. Suzuki, and Y. Moriyoshi: Fabrication of oriented ß-alumina from porous bodies by slip casting in a high magnetic field. Solid State Ionics 172, 341 (2004).

Y. Sakka, T.S. Suzuki, and T. Uchikoshi: Fabrication and some properties of textured alumina-related compounds by colloidal processing in high-magnetic field and sintering. J. Eur. Ceram. Soc. 28, 935 (2008).

V.V. Kharton, F.M.B. Marques, and A. Atkinson: Transport properties of solid oxide electrolyte ceramics: A brief review. Solid State Ionics 174, 135 (2004).

K.R. Kendall, C. Navas, J.K. Thomas, and H-C. Zur Loye: Recent developments in oxide ion conductors: Aurivillius phases. Chem. Mater. 8, 642 (1996).

N. Mahato, A. Banerjee, A. Gupta, S. Omar, and K. Balani: Progress in material selection for solid state oxide fuel cell technology: A review. Prog. Mater. Sci. 72, 141 (2015).

L. Malavasi, C.A.J. Fisher, and M.S. Islam: Oxide-ion and proton conducting electrolyte materials for clean energy applications: Structural and mechanistic features. Chem. Soc. Rev. 39, 4370 (2010).

K. Fukuda, T. Asaka, S. Hara, M. Oyabu, A. Berghout, E. Béchade, O. Masson, I. Julien, and P. Thomas: Crystal structure and oxide-ion conductivity along c-axis of Si-deficient apatite-type lanthanum silicate. Chem. Mater. 25, 2154 (2013).

K. Fukuda, M. Okabe, and T. Asaka: Microtexture of c -axis-oriented polycrystalline lanthanum silicate oxyapatite formed by reactive diffusion. J. Am. Ceram. Soc. 99, 2816 (2016).

D.L. Medlin and G.J. Snyder: Interfaces in bulk thermoelectric materials: A review for current opinion in colloid and interface science. Curr. Opin. Colloid Interface Sci. 14, 226 (2009).

H. Ohta, W-S. Seo, and K. Koumoto: Thermoelectric properties of homologous compounds in the ZnO–In2O3 system. J. Am. Ceram. Soc. 79, 2193 (1996).

I. Terasaki, Y. Sasago, and K. Uchinokura: Large thermoelectric power in NaCo2O4 single crystals. Phys. Rev. B: Condens. Matter Mater. Phys. 56, R12685 (1997).

S. Li, R. Funahashi, I. Matsubara, K. Ueno, and H. Yamada: High temperature thermoelectric properties of oxide Ca9Co12O28. J. Mater. Chem. 9, 1659 (1999).

J. Hejtmánek, M. Veverka, K. Knížek, H. Fujishiro, S. Hebert, Y. Klein, A. Maignan, C. Bellouard, and B. Lenoir: Cobaltites as Perspective Thermoelectrics, edited by J. Yang (Mater. Res. Soc. Symp. Proc. 886, Warrendale, PA, 2006) 1274-F01-07.1.

H. Itahara, S. Tajima, and T. Tani: Synthesis of β-Co(OH)2 platelets by precipitation and hydrothermal methods. J. Ceram. Soc. Jpn. 110, 1048 (2002).

K. Koumoto, R. Funahashi, E. Guilmeau, Y. Miyazaki, A. Weidenkaff, Y. Wang, and C. Wan: Thermoelectric ceramics for energy harvesting. J. Am. Ceram. Soc. 96(1), 1 (2013).

Y. Zhou, I. Matsubara, S. Horii, T. Takeuchi, R. Funahashi, M. Shikano, J. Shimoyama, K. Kishio, W. Shin, N. Izu, and N. Murayama: Thermoelectric properties of highly grain-aligned and densified Co-based oxide ceramics. J. Appl. Phys. 93, 2653 (2003).

R. Funahashi, S. Urata, T. Sano, and M. Kitawaki: Enhancement of thermoelectric figure of merit by incorporation of large single crystals in Ca3Co4O9 bulk materials. J. Mater. Res. 18, 1646 (2003).

M. Prevel, E.S. Reddy, O. Perez, W. Kobayashi, I. Terasaki, C. Goupil, and J.G. Noudem: Thermoelectric properties of sintered and textured Nd-Substituted Ca3Co4O9 ceramics. JJAP 46, 97 (2007).

M. Prevel, S. Lemonnier, Y. Klein, S. Hebert, D. Chateigner, B. Ouladdiaf, and J.G. Noudem: Textured Ca3Co4O9 thermoelectric oxides by thermoforging process. J. Appl. Phys. 98, 093706 (2005).

E. Guilmeau, R. Funahashi, M. Mikami, K. Chong, and D. Chateigner: Thermoelectric properties-texture relationship in highly oriented Ca3Co4O9 composited. Appl. Phys. Lett. 85, 1490 (2004).

Y.H. Liu, Y.H. Lin, Z. Shi, C.W. Nan, and Z.J. Shen: Preparation of Ca3Co4O9 and improvement of its thermoelectric properties by spark plasma sintering. J. Am. Ceram. Soc. 88, 1337 (2005).

H.Q. Liu, Y. Song, S.N. Zhang, X.B. Zhao, and F.R. Wang: Thermoelectric properties of Ca3−xYxCo4O9+δ ceramics. J. Phys. Chem. Solids 70, 600 (2009).

J.G. Noudem, D. Kenfaui, D. Chateigner, and M. Gomina: Granular and lamellar thermoelectric oxides consolidated by spark plasma sintering. J. Electron. Mater. 40, 1100 (2011).

H. Itahara, J. Sugiyama, and T. Tani: Enhancement of electrical conductivity in thermoelectric [Ca2CoO3]0.62[CoO2] ceramics by texture improvement. Jpn. J. Appl. Phys. 43, 5134 (2004).

S. Lee, R.H.T. Wilke, S. Trolier-McKinstry, S. Zhang, and C.A. Randall: SrxBa1−xNb2O6−δ ferroelectric-thermoelectrics: Crystal anisotropy, conduction mechanism, and power factor. Appl. Phys. Lett. 96, 031910 (2010).

S. Lee, S. Dursun, C. Duran, and C.A. Randall: Thermoelectric power factor enhancement of textured ferroelectric SrxBa1−xNb2O6−δ. J. Mater. Res. 26(1), 26 (2011).

Y. Miwa, S. Kawada, M. Kimura, S. Omiya, N. Kubodera, A. Ando, T.S. Suzuki, T. Uchikoshi, and Y. Sakka: Processing and enhanced piezoelectric properties of highly oriented compositionally modified Pb(Zr,Ti)O3 ceramics fabricated by magnetic alignment. Appl. Phys. Express 8, 041501 (2015).

E.M. Sabolsky, S. Trolier-McKinstry, and G.L. Messing: Dielectric and piezoelectric properties of 〈001〉 fiber-textured 0.675 Pb(Mg1/3Nb2/3)O3–0.325PbTiO3 ceramics. J. Appl. Phys. 93, 4072 (2003).

T. Richter, S. Denneler, C. Schuh, E. Suvaci, and R. Moos: Textured PMN–PT and PMN–PZT. J. Am. Ceram. Soc. 91, 929 (2008).

Y. Yan, Y.U. Wang, and S. Priya: Electromechanical behavior of [001]-textured Pb(Mg1/3Nb2/3)O3–PbTiO3 ceramics. Appl. Phys. Lett. 100, 192950 (2012).

K.H. Brosnan: Processing, properties, and application of textured 0.72Pb(Mg1/3Nb2/3)O3–0.28PbTiO3 ceramics. Ph.D thesis, Pennsylvania State University, 2007.

H. Amorin, H. Ursic, P. Ramos, J. Holc, R. Moreno, D. Chateigner, J. Ricote, and M. Alguero: Pb(Mg1/3Nb2/3)O3–PbTiO3 textured ceramics with high piezoelectric response by a novel templated grain growth approach. J. Am. Ceram. Soc. 97, 420 (2014).

S.F. Poterala, S. Trolier-McKinstry, R.J. Meyer, Jr., and G.L. Messing: Processing, texture quality, and piezoelectric properties of 〈001〉C textured (1 −x)Pb(Mg1/3Nb2/3)TiO3–x PbTiO3 ceramics. J. Appl. Phys. 110, 14105 (2011).

Y. Yan, L. Yang, Y. Zhou, K.H. Cho, J.S. Heo, and S. Priya: Enhanced temperature stability in 〈111〉 textured tetragonal Pb(Mg1/3Nb2/3)O3–PbTiO3 piezoelectric ceramics. J. Appl. Phys. 118, 104101 (2015).

Y. Yan, J.E. Zhou, D. Maurya, Y.U. Wang, and S. Priya: Giant piezoelectric voltage coefficient in grain-oriented modified PbTiO3 material. Nat. Commun. 7, 1 (2016).

Y. Chang, J. Wu, Y. Sun, S. Zhang, X. Wang, B. Yang, G.L. Messing, and W. Cao: Enhanced electromechanical properties and phase transition temperatures in [001] textured Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 ternary ceramics. Appl. Phys. Lett. 107, 82902 (2015).

D. Wei, Q. Yuan, G. Zhang, and H. Wang: Templated grain growth and piezoelectric properties of 〈001〉-textured PIN–PMN–PT ceramics. J. Mater. Res. 30, 2144 (2015).

C. Duran, S. Dursun, and E. Akça: High strain, 〈001〉-textured Pb(Mg1/3Nb2/3)O3–Pb(Yb1/2Nb1/2)O3–PbTiO3 piezoelectric ceramics. Scr. Mater. 113, 14 (2016).

Y. Yan, K. Cho, D. Maurya, A. Kumar, S. Kalinin, K. Armen, and S. Priya: Giant energy density in [001]-textured Pb(Mg1/3Nb2/3)O3–PbZrO3–PbTiO3 piezoelectric ceramics. Appl. Phys. Lett. 102, 42903 (2013).

Y. Yan and S. Priya: Strong piezoelectric anisotropy d15/ d33 in 〈111〉 textured Pb(Mg1/3Nb2/3)O3–Pb(Zr,Ti)O3 ceramics. Appl. Phys. Lett. 107, 82909 (2015).

S.J. Zhang, J. Luo, W. Hackenberger, N.P. Sherlock, R.J. Meyer, Jr., and T.R. Shrout: Electromechanical characterization of Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)–PbTiO3 crystals as a function of crystallographic orientation and temperature. J. Appl. Phys. 105, 104506 (2009).

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, and M. Nakamura: Lead-free piezoceramics. Nature 432, 84 (2004).

Z.P. Yang, Y.F. Chang, and L.L. Wei: Phase transitional behavior and electrical properties of lead-free (K0.44Na0.52Li0.04)(Nb0.96−xTaxSb0.04)O3 piezoelectric ceramics. Appl. Phys. Lett. 90, 042911 (2007).

J.G. Wu and D.Q. Xiao: Compositional dependence of phase structure and electrical properties in (K0.42Na0.58)NbO3–LiSbO3 lead-free ceramics. J. Appl. Phys. 102, 114113 (2007).

J. Fuentes, J. Portelles, M.D. Durruthy-Rodriguez, H. H’Mok, O. Raymond, J. Heiras, M.P. Cruz, and J.M. Siqueiros: Dielectric and piezoelectric properties of the KNN ceramic compound doped with Li, La and Sb. Appl. Phys. A 117, 709 (2015).

Y.B. Wei, Z. Wu, Y.M. Jia, J. Wu, Y.C. Shen, and H.S. Luo: Dual-enhancement of ferro-/piezoelectric and photoluminescent performance in Pr3+ doped (K0.5Na0.5)NbO3 lead-free ceramics. Appl. Phys. Lett. 105, 042902 (2014).

Y. Chang, S.F. Poterala, Z. Yang, S. Trolier-McKinstry, and G.L. Messing: 〈001〉 textured (K0.5Na0.5)(Nb0.97Sb0.03)O3 piezoelectric ceramics with high electromechanical coupling over a broad temperature range. Appl. Phys. Lett. 95, 232905 (2009).

Y. Chang, S. Poterala, Z. Yang, and G.L. Messing: Enhanced electromechanical properties and temperature stability of textured (K0.5Na0.5)NbO3-based piezoelectric ceramics. J. Am. Ceram. Soc. 94, 2494 (2011).

H. Takao, Y. Saito, Y. Aoki, and K. Horibuchi: Microstructural evolution of crystalline-oriented (K0.5Na0.5)NbO3 piezoelectric ceramics with a pintering aid of CuO. J. Am. Ceram. Soc. 89, 1951 (2006).

A. Hussain, J.S. Kim, T.K. Song, M.H. Kim, W.J. Kim, and S.S. Kim: Fabrication of textured KNNT ceramics by reactive template grain growth using NN templates. Curr. Appl. Phys. 13, 1055 (2013).

Y. Saito and H. Takao: Synthesis of polycrystalline platelike KNbO3 particles by the topochemical micro-crystal conversion method and fabrication of grain-oriented (K0.5Na0.5)NbO3 ceramics. J. Eur. Ceram. Soc. 27, 4085 (2007).

A.B. Haugen, G. Henning, F. Madaro, M.I. Morozov, G. Tutuncu, J.L. Jones, T. Grande, and M. Einarsrud: Piezoelectric K0.5Na0.5NbO3 ceramics textured using needlelike K0.5Na0.5NbO3 templates. J. Am. Ceram. Soc. 97, 3818 (2014).

Y. Li, C. Hui, M. Wu, Y. Li, and Y. Wang: Textured (K0.5Na0.5)NbO3 ceramics prepared by screen-printing multilayer grain growth technique. Ceram. Int. 38S, S283 (2012).

G. Tutuncu, Y. Chang, S. Poterala, J.L. Jones, and G.L. Messing: In situ observations of template grain growth in (Na0.5K0.5)0.98Li0.02NbO3 piezoceramics: Texture development and template-matrix interactions. J. Am. Ceram. Soc. 95, 2653 (2012).

F. Gao, R.Z. Hong, J.J. Li, Y.H. Yao, and C.S. Tian: Effect of different templates on microstructure of textured Na0.5Bi0.5TiO3–BaTiO3 ceramics with RTGG method. J. Eur. Ceram. Soc. 28, 2063 (2008).

W. Bai, J. Hao, F. Fu, W. Li, B. Shen, and J. Zhai: Structure and strain behavior of 〈001〉 textured BNT-based ceramics by template grain growth. Mater. Lett. 97, 137 (2013).

M. Deng, X. Li, Z. Zhao, T. Li, Y. Dai, and H. Ji: Crystallographic textured evolution in 0.85Na0.5Bi0.5TiO3–0.04BaTiO3–0.11K0.5Bi0.5TiO3 ceramics prepared by reactive-templated grain growth method. J. Mater. Sci. Mater. Electron. 25, 1873 (2014).

F. Gao, X. Liu, C. Zhang, L. Cheng, and C. Tian: Fabrication and electrical properties of textured (Na,K)0.5Bi0.5TiO3 ceramics by reactive-templated grain growth. Ceram. Int. 34, 403 (2008).

D. Hu, K. Mori, X. Kong, K. Shinagawa, S. Wada, and Q. Feng: Fabrication of [100]-oriented bismuth sodium titanate ceramics with small grain size and high density for piezoelectric materials. J. Eur. Ceram. Soc. 34, 1169 (2014).

H. Zou, Y. Sui, X. Zhu, B. Liu, J. Xue, and J. Zhang: Texture development and enhanced electromechanical properties in 〈001〉-textured BNT-based materials. Mater. Lett. 184, 139 (2016).

T. Shoji, Y. Yoshida, and T. Kimura: Mechanism of texture development in Bi0.5(Na,K)0.5TiO3 templated by platelike Al2O3 particles. J. Am. Ceram. Soc. 91, 3883 (2008).

T. Shoji, K. Fuse, and T. Kimura: Mechanism of texture development in Bi0.5(Na,K)0.5TiO3 prepared by the templated grain growth process. J. Am. Ceram. Soc. 92, S140 (2009).

X. Jing, Y. Li, Q. Yang, J. Zeng, and Q. Yin: Influence of different templates on the textured Bi0.5(Na1−xKx)0.5TiO3 piezoelectric ceramics by the reactive templated grain growth process. Ceram. Int. 30, 1889 (2004).

D. Maurya, Y. Zhou, Y. Yan, and S. Priya: Synthesis mechanism of grain-oriented lead-free piezoelectric Na0.5Bi0.5TiO3–BaTiO3 ceramics with giant piezoelectric response. J. Mater. Chem. C 1, 2102 (2013).

D. Maurya, Y. Zhou, Y. Wang, Y.K. Yan, J.F. Li, D. Viehland, and S. Priya: Giant strain with ultra-low hysteresis and high temperature stability in grain oriented lead-free K0.5Bi0.5TiO3–BaTiO3–Na0.5Bi0.5TiO3 piezoelectric materials. Sci. Rep. 5, 8595 (2014).

H. Zhang, P. Xu, E. Patterson, J. Zang, S. Jiang, and J. Rödel: Preparation and enhanced electrical properties of grain-oriented (Bi1/2Na1/2)TiO3-based lead-free incipient piezoceramics. J. Eur. Ceram. Soc. 35, 2501 (2015).

S. Ma, Y. Zhang, Z. Liu, X. Dai, and J. Huang: Preparation and enhanced electric-field-induced strain of textured 91BNT–6BT–3KNN lead-free piezoceramics by TGG method. J. Mater. Sci. Mater. Electron. 27, 3076 (2016).

D. Vriami, D. Damjanovic, J. Vleugels, and O. Van Der Biest: Textured BaTiO3 by templated grain growth and electrophoretic deposition. J. Mater. Sci. 50, 7896 (2015).

F. Fu, B. Shen, Z. Xu, and J. Zhai: Electric properties of BaTiO3 lead-free textured piezoelectric thick film by screen printing method. J. Electroceram. 33, 208 (2014).

S. Wada, K. Takeda, T. Muraishi, H. Kakemoto, T. Tsurumi, and T. Kimura: Preparation of [110] grain oriented barium titanate ceramics by templated grain growth method and their piezoelectric properties. Jpn. J. Appl. Phys. 46, 739 (2007).

A.N. Kamlo, P.M. Geffroy, M. Pham-Thi, and P. Marchet: +111−-Textured BaTiO3 ceramics elaborated by templated grain growth using NaNbO3 templates. Mater. Lett. 113, 149 (2013).

W. Liu and X. Ren: Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. 103, 257602 (2009).

T. Sato and T. Kimura: Preparation of 〈111〉 textured BaTiO3 ceramics by templated grain growth method using novel template particles. Ceram. Int. 34, 757 (2008).

S.K. Ye, J.Y.H. Fuh, and L. Lu: Structure and electrical properties of 〈001〉 textured (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 lead-free piezoelectric ceramics. Appl. Phys. Lett. 100, 252906 (2012).

E.M. Sabolsky, L. Maldonado, M.M. Seabaugh, and S.L. Swartz: Textured-Ba(Zr,Ti)O3 piezoelectric ceramics fabricated by templated grain growth (TGG). J. Electroceram. 25, 77 (2010).

W. Bai, D. Chen, P. Li, B. Shen, J. Zhai, and Z. Ji: Enhanced electromechanical properties in 〈001〉-textured (Ba0.85Ca0.15) (Zr0.1Ti0.9)O3 lead-free piezoceramics. Ceram. Int. 42, 3429 (2016).

S. Zhukov, Y.A. Genenko, J. Koruza, J. Schultheiß, H.v. Seggern, W. Sakamoto, H. Ichikawa, T. Murata, K. Hayashi, and T. Yogo: Effect of texturing on polarization switching dynamics in ferroelectric ceramics. Appl. Phys. Lett. 108, 012907 (2016).

J. Schultheiß, O. Clemens, S. Zhukov, H.v. Seggern, W. Sakamoto, and J. Koruza: Effect of degree of crystallographic texture on ferro- and piezoelectric properties of Ba0.85Ca0.15TiO3 piezoceramics. J. Am. Ceram. Soc. (2017). doi: https://doi.org/10.1111/jace.14749.

S. Ye, J. Fuh, L. Lu, Y-I. Chang, and J-R. Yang: Structure and properties of hot-pressed lead-free (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 piezoelectric ceramics. RSC Adv. 3, 20693 (2013).

S. Endo, H. Nagata, and T. Takenaka: Fabrication and high power piezoelectric characteristics of textured (Sr0.7Ca0.3)2Bi4Ti5O18. Jpn. J. Appl. Phys. 53, 3 (2014).

H. Zhang, H. Yan, X. Zhang, M.J. Reece, J. Liu, Z. Shen, Y. Kan, and P. Wang: The effect of texture on the properties of Bi3.15Nd0.85Ti3O12 ceramics prepared by spark plasma sintering. Mater. Sci. Eng., A 475, 92 (2008).

T. Kimura, Y. Sakuma, and M. Murata: Texture development in piezoelectric ceramics by templated grain growth using heterotemplates. J. Eur. Ceram. Soc. 25, 2227 (2005).

M. Kimura, H. Ogawa, T. Sawada, K. Shiratsuyu, N. Wada, and A. Ando: Piezoelectric properties in textured ceramics of bismuth layer-structured ferroelectrics. J. Electroceram. 21, 55 (2008).

H. Chen, B. Shen, J. Xu, and J. Zhai: Textured Ca0.85(Li,Ce)0.15Bi4Ti4O15 ceramics for high temperature piezoelectric applications. Mater. Res. Bull. 47, 2530 (2012).

H. Chen and J. Zhai: Enhanced piezoelectric properties of CaBi2Nb2O9 with Eu modification and templated grain growth. Key Eng. Mater. 515, 1367 (2012).

H. Hao, H. Liu, and S. Ouyang: Processing and property of textured lead-free SrTi4Bi4O15 piezoelectric ceramics. J. Electroceram. 21, 255 (2008).

T. Li, X. Li, Z. Zhao, H. Ji, and Y. Dai: Structures and electrical properties of textured Ca0.85(LiCe)0.075Bi4Ti4O15 ceramics prepared by the reactive templated grain growth. Integr. Ferroelectr. 162, 1 (2015).

J. Liu, Z. Shen, M. Nygren, Y. Kan, and P. Wang: SPS processing of bismuth-layer structured ferroelectric ceramics yielding highly textured microstructures. J. Eur. Ceram. Soc. 26, 3233 (2006).

Q.X. Bao, L.H. Zhu, Q.W. Huang, and J. Xv: Preparation of textured Ba2NaNb5O15 ceramics by templated grain growth. Ceram. Int. 32(7), 745 (2006).

S. Dursun, E. Mensur-Alkoy, and S. Alkoy: Fabrication of textured lead-free strontium barium niobate (SBN61) bulk ceramics and their electrical properties. J. Eur. Ceram. Soc. 36, 2479 (2016).

Y. Chang, S. Lee, S. Poterala, C.A. Randall, and G.L. Messing: A critical evaluation of reactive templated grain growth (RTGG) mechanisms in highly [001] textured Sr0.61Ba0.39Nb2O6 ferroelectric-thermoelectrics. J. Mater. Res. 26(24), 3044 (2011).

L. Wei, X. Chao, X. Han, and Z. Yang: Structure and electrical properties of textured Sr1.85Ca0.15NaNb5O15 ceramics prepared by reactive templated grain growth. Mater. Res. Bull. 52, 65 (2014).

L. Liu and Z. Hou: Fabrication of grain-oriented KSr2Nb5O15 ceramics by a brush technique. Mater. Lett. 186, 105 (2017).

S. Alkoy and S. Dursun: Processing and properties of textured potassium strontium niobate (KSr2Nb5O15) ceramic fibers—Texture development. J. Am. Ceram. Soc. 95(3), 937 (2012).

S. Alkoy and S. Dursun: Processing and properties of textured potassium strontium niobate (KSr2Nb5O15) ceramic fibers-effect of texture on the electrical properties. IEEE Trans. Ultrason., Ferroelectr., Freq. Control 60, 2044 (2013).

S. Tanaka, T. Takahashi, and R. Furushima: Fabrication of c-axis-oriented potassium strontium niobate (KSr2Nb5O15) ceramics by a rotating magnetic field and electrical property. J. Ceram. Soc. Japan 118, 722 (2010).

R. Apetz and M.P.B. van Bruggen: Transparent alumina: A light-scattering model. J. Am. Ceram. Soc. 86, 480 (2003).

P. Liu, H. Yi, G. Zhou, J. Zhang, and S. Wang: HIP and pressureless sintering of transparent alumina shaped by magnetic field assisted slip casting. Opt. Mater. Exp. 5, 441 (2015).

A. Pringuet, T. Takahashi, S. Baba, Y. Kamo, Z. Kato, K. Uematsu, and S. Tanaka: Fabrication of transparent grain-oriented polycrystalline alumina by colloidal processing. J. Am. Ceram. Soc. 99, 3217 (2016).

S. Tanaka, T. Takahashi, and K. Uematsu: Fabrication of transparent crystal-oriented polycrystalline strontium barium niobate ceramics for electro-optical application. J. Eur. Ceram. Soc. 34, 3723 (2014).

J. Akiyama, Y. Sato, and T. Taira: Laser demonstration of diode-pumped Nd3+-doped fluorapatite anisotropic ceramics. Appl. Phys. Exp. 4, 002703 (2011).

Y. Sato, J. Akiyama, and T. Taira: Micro-domain controlled anisotropic laser ceramics assisted by rare-earth trivalent, in Pacific Rim Laser Damage 2011: Optical Materials for High Power Lasers, edited by J. Shao, K. Sugioka, and C.J. Stolz (Proc. of SPIE 8206, Bellingham, WA, 2012) p. 82061T-1.

Y. Sato, M. Arzakantsyan, J. Akiyama, and T. Taira: Anisotropic Yb:FAP laser ceramics by micro-domain control. Opt. Mater. Exp. 4, 214969 (2006).

I. Shoji, Y. Sato, S. Kurimura, V. Lupei, T. Taira, A. Ikesue, and K. Yoshida: Thermal-birefringence-induced depolarization in Nd:YAG ceramics. Opt. Lett. 27, 234 (2002).

I. Shoji and T. Taira: Intrinsic reduction of the depolarization loss in solid-state lasers by use of a (110)-cut Y3Al5O12 crystal. Appl. Phys. Lett. 80, 3048 (2002).

S. Arakawa, H. Kadoura, T. Uyama, K. Takatori, Y. Takeda, and T. Tani: Formation of preferentially oriented Y3Al5O12 film on a reactive sapphire substrate: Phase and texture transitions from Y2O3. J. Eur. Ceram. Soc. 36, 663 (2016).

K. Watari: High thermal conductivity non-oxide ceramics. J. Ceram. Soc. Jpn. 109, S7 (2001).

N. Hirosaki, S. Ogata, C. Kocer, H. Kitagawa, and Y. Nakamura: Molecular dynamics calculation of the ideal thermal conductivity of single-crystal. Phys. Rev. B: Condens. Matter Mater. Phys. 65, 134110 (2002).

T.S. Suzuki and Y. Sakka: Preparation of oriented bulk 5 wt% Y2O3–AlN ceramics by slip casting in a high magnetic field and sintering. Scr. Mater. 52, 583 (2005).

T.S. Suzuki, T. Uchikoshi, and Y. Sakka: Effect of sintering additive on crystallographic orientation in AlN prepared by slip casting in a strong magnetic field. J. Eur. Ceram. Soc. 29, 2627 (2009).

B. Li, L. Pottier, J.P. Roger, D. Fournier, K. Watari, and K. Hirao: Measuring the anisotropic thermal diffusivity of silicon nitride grains by thermoreflectance microscopy. J. Eur. Ceram. Soc. 19, 1631 (1999).

X. Zhu, T.S. Suzuki, T. Uchikoshi, and Y. Sakka: Texturing behavior in sintered reaction-bonded silicon nitride via strong magnetic field alignment. J. Eur. Ceram. Soc. 28, 929 (2008).

X.W. Zhu, Y. Sakka, Y. Zhou, K. Hirao, and K. Itatani: A strategy for fabricating textured silicon nitride with enhanced thermal conductivity. J. Eur. Ceram. Soc. 34, 2585 (2014).

K. Hirao, K. Watari, M.E. Brito, M. Toriyama, and S. Kanzaki: High thermal conductivity in silicon nitride with anisotropic microstructure. J. Am. Ceram. Soc. 79, 2485 (1996).

Y. Akimune, F. Munakata, K. Matsuo, N. Hirosaki, Y. Okamoto, and K. Misono: Raman spectroscopy analysis of structural defects in hot isostatically pressed silicon nitride. J. Ceram. Soc. Jpn. 107, 339 (1999).

McColm: Ceramic Hardness, 1st ed. (Plenum Press, New York, 1990).

T. Carisey, I. Levin, and D.G. Brandon: Microstructure and mechanical properties of textured Al2O3. J. Eur. Ceram. Soc. 15, 283 (1995).

S. Lee, Y. Lee, Y. Kim, R. Xie, M. Mitomo, and G. Zhan: Mechanical properties of hot-forged silicon carbide ceramics. Scr. Mater. 52, 153 (2005).

V.R. Vedula, S.J. Glass, D.M. Saylor, G.S. Rohrer, W.C. Carter, S.A. Langer, and E.R. Fuller, Jr.: Residual stress predictions in polycrystalline alumina. J. Am. Ceram. Soc. 84, 2947 (2001).

J.A. Salem, J.L. Shannon, and R.C. Bradt: The effect of texture on the crack growth resistance of alumina. Presented at the 89th Annual Meeting of the American Ceramic Society (1987). Available at: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19880004824.pdf (accessed 20 December 2016).

L. Zhang, J. Vleugels, L. Darchuk, and O. Van der Biest: Magnetic field oriented tetragonal zirconia with anisotropic toughness. J. Eur. Ceram. Soc. 31, 1405 (2011).

R. Pavlacka, R. Bermejo, Y. Chang, D.J. Green, and G.L. Messing: Fracture behavior of layered alumina microstructural composites with highly textured layers. J. Am. Ceram. Soc. 96, 1577 (2013).

Y. Chang, R. Bermejo, and G.L. Messing: Improved fracture behavior of alumina microstructural composites with highly textured compressive layers. J. Am. Ceram. Soc. 97, 3643 (2014).

M-Y. He and J.W. Hutchinson: Crack deflection at an interface between dissimilar elastic materials. Int. J. Solids Struct. 25, 1053 (1989).

M. Nakamura, K. Hirao, Y. Yamauchi, and S. Kanzaki: Tribological properties of unidirectionally aligned silicon nitride. J. Am. Ceram. Soc. 84, 2579 (2001).

W. Wu, Y. Sakka, and T.S. Suzuki: Microstructure and anisotropic properties of textured ZrB2 and ZrB2–MoSi2 ceramics prepared by strong magnetic field alignment. Int. J. Appl. Ceram. Technol. 11, 218 (2014).

X. Zhu and Y. Sakka: Textured silicon nitride: Processing and anisotropic properties. Sci. Technol. Adv. Mater. 9, 1 (2008).

R. Pavlacka and G. Messing: Processing and mechanical response of highly textured Al2O3. J. Eur. Ceram. Soc. 30, 2917 (2010).

Z.M. Sun: Progress in research and development on MAX phases: A family of layered ternary compounds. Int. Mater. Rev. 56, 143 (2011).

M. Shamma, E.N. Caspi, B. Anasori, B. Clausen, D.W. Brown, S.C. Vogel, V. Presser, S. Amini, O. Yeheskel, and M.W. Barsoum: In situ neutron diffraction evidence for fully reversible dislocation motion in highly textured polycrystalline Ti2AlC samples. Acta Mater. 98, 51 (2015).

C. Hu, Y. Sakka, H. Tanaka, T. Nishimura, and S. Grasso: Fabrication of textured Nb4AlC3 ceramic by slip casting in a strong magnetic field and spark plasma sintering. J. Am. Ceram. Soc. 94, 410 (2011).

C. Hu, Y. Sakka, T. Nishimura, S. Guo, S. Grasso, and H. Tanaka: Physical and mechanical properties of highly textured polycrystalline Nb4AlC3 ceramic. Sci. Technol. Adv. Mater. 12, 044603 (2011).

C. Hu, Y. Sakka, S. Grasso, T. Nishimura, S. Guo, and H. Tanaka: Shell-like nanolayered Nb4AlC3 ceramic with high strength and toughness. Scr. Mater. 64, 765 (2011).

C. Hu, Y. Sakka, S. Grasso, T. Suzuki, and H. Tanaka: Tailoring Ti3SiC2 ceramic via a strong magnetic field alignment method followed by spark plasma sintering. J. Am. Ceram. Soc. 94, 742 (2011).

K. Sato, M. Mishra, H. Hirano, T.S. Suzuki, and Y. Sakka: Fabrication of textured Ti3SiC2 ceramic by slip casting in a strong magnetic field and pressureless sintering. J. Ceram. Soc. Jpn. 122, 817 (2014).

H.B. Zhang, C.F. Hu, K. Sato, S. Grasso, M. Estili, S.Q. Guo, K. Morita, H. Yoshida, T. Nishimura, T.S. Suzuki, M.W. Barsoum, B.N. Kim, and Y. Sakka: Tailoring Ti3AlC2 ceramic with high anisotropic physical and mechanical properties. J. Eur. Ceram. Soc. 393, 35 (2015).

M. Mishra, Y. Sakka, C. Hu, T.S. Suzuki, T. Uchikoshi, and L. Besra: Textured Ti3SiC2 by EPD in a strong magnetic field. Key Eng. Mater. 507, 15 (2012).

Y. Mizuno, K. Sato, M. Mrinalini, T.S. Suzuki, and Y. Sakka: Fabrication of textured Ti3AlC2 by spark plasma sintering and their anisotropic mechanical properties. J. Ceram. Soc. Jpn. 121, 366 (2013).

T. Lapauw, K. Vanmeensel, K. Lambrinou, and J. Vleugels: A new method to texture dense Mn+1AXn ceramics by spark plasma deformation. Scr. Mater. 111, 98 (2016).

V.I. Aleshin, I.P. Raevskii, and E.I. Sitalo: Electromechanical properties of a textured ceramic material in the (1 −x)PMN–x PT system: Simulation based on the effective-medium method. Phys. Solid State 50, 2150 (2008).

M. Pham-Thi, H. Hemery, and H. Dammak: X-ray investigation of highly oriented (1 −x)PbMg1/3Nb2/3O3–(x)PbTiO3 ceramics. J. Eur. Ceram. Soc. 25, 2433 (2005).

S.F. Poterala, R.J. Meyer, and G.L. Messing: Low-field dynamic magnetic alignment and templated grain growth of diamagnetic PMN–PT ceramics. J. Mater. Res. 28, 2961 (2013).

J.L. Jones, E.B. Slamovich, and K.J. Bowman: Critical evaluation of the Lotgering degree of orientation texture indicator. J. Mater. Res. 19, 3414 (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was Editor in Chief during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Messing, G.L., Poterala, S., Chang, Y. et al. Texture-engineered ceramics—Property enhancements through crystallographic tailoring. Journal of Materials Research 32, 3219–3241 (2017). https://doi.org/10.1557/jmr.2017.207

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.207