Abstract

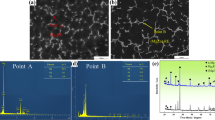

This study investigated the effects of 1 wt% SiC nanoparticles addition on the microstructures and mechanical properties of Mg9Al–1Si (wt%) alloy subjected to equal channel angular pressing (ECAP). Results showed that addition of SiC nanoparticles could refine matrix grain, Mg17Al12 and Mg2Si phase of as-cast alloy, but the Mg17Al12 phase still exhibited network structure and the morphology of Mg2Si phase was still Chinese-script type. During the ECAP process, network Mg17Al12 and Chinese-script shaped Mg2Si phases were partially broken down into fine particles (∼10 µm) and much finer particles (∼2 µm) respectively. In particular, these Mg17Al12 and Mg2Si particles were uniform distribution in ECAPed Mg9Al–1Si–1SiC composite. The well-distributed particles and the existence of SiC nanoparticles could promote the formation of fine DRXed grains through enhanced grain boundary pinning. During tensile testing at room temperature, ECAPed Mg9Al–1Si–1SiC composite exhibit optimal mechanical properties, the ultimate tensile strength and elongation to failure were reached to 255 MPa and 7.9%, respectively. Furthermore, at elevated temperature of 150 °C, the tensile strength and elongation to failure were considerably increased compared to an ECAPed, SiC-free Mg9Al–1Si alloy.

Similar content being viewed by others

References

K.B. Nie, K.K. Deng, X.J. Wang, W.M. Gan, F.J. Xu, K. Wu, and M.Y. Zheng: Microstructures and mechanical properties of SiCp/AZ91 magnesium matrix nanocomposites processed by multidirectional forging. J. Alloys Compd. 622, 1018 (2015).

J.Y. Li, J.X. Xie, J.B. Jin, and Z.X. Wang: Microstructural evolution of AZ91 magnesium alloy during extrusion and heat treatment. Trans. Nonferrous Met. Soc. China 22, 1028 (2012).

X. Xie, J. Shen, L. Cheng, Y. Li, and Y.Y. Pu: Effects of nano-particles strengthening activating flux on the microstructures and mechanical properties of TIG welded AZ31 magnesium alloy joints. Mater. Des. 81, 31 (2015).

S.Y. Song, X. Zhou, L. Li, and W.M. Ma: Numerical simulation and experimental validation of SiC nanoparticle distribution in magnesium melts during ultrasonic cavitation based processing of magnesium matrix nanocomposites. Ultrason. Sonochem. 24, 43 (2015).

R. Alizadeh and R. Mahmudi: Effects of Sb addition on the modification of Mg2Si particles and high-temperature mechanical properties of cast Mg–4Zn–2Si alloy. J. Alloys Compd. 509, 9195 (2011).

B.G. Moon, B.S. You, and Y.D. Hahn: Effects of aluminum and strontium content on the microstructures and mechanical properties of Mg–Al–Ca–Sr alloys. Curr. Nanosci. 10, 108 (2014).

H.X. Wang, B. Zhou, Y.T. Zhao, K.K. Zhou, W.L. Cheng, and W. Liang: Effect of Si addition on the microstructure and mechanical properties of ECAPed Mg–15Al alloy. Mater. Sci. Eng., A 589, 119 (2014).

H.X. Wang, W. Liang, J.B. Xue, X.G. Zhao, L.P. Bian, and J.S. Zhang: Microstructure and mechanical properties of ultrafine grained Mg15Al alloy processed by equal-channel angular pressing. J. Wuhan Univ. Technol., Mater. Sci. Ed. 25, 238 (2010).

K.B. Nie, X.J. Wang, X.S. Hu, L. Xu, K. Wu, and M.Y. Zheng: Microstructure and mechanical properties of SiC nanoparticles reinforced magnesium matrix composites fabricated by ultrasonic vibration. Mater. Sci. Eng., A 528, 5278 (2011).

S.Y. Liu, W.Z. Li, X. Zhu, and G.J. He: Tensile properties and fracture behavior of nano-sized SiC particles reinforced AZ91D composites at elevated temperature. Rare Met. Mater. Eng. 42 (4), 761 (2013).

K.B. Nie, X.J. Wang, K. Wu, X.S. Hu, M.Y. Zheng, and L. Xu: Microstructure and tensile properties of micro-SiC particles reinforced magnesium matrix composites produced by semisolid stirring assisted ultrasonic vibration. Mater. Sci. Eng., A 528, 8709 (2011).

K.K. Deng, C.J. Wang, J.Y. Shi, Y.W. Wu, and K. Wu: Microstructure evolution mechanism of micron particle reinforced magnesium matrix composite at room temperature. Mater. Chem. Phys. 134, 581 (2012).

S.S. Zhou, K.K. Deng, J.C. Li, K.B. Nie, F.J. Xu, H.F. Zhou, and J.F. Fan: Hot deformation behavior and workability characteristics of bimodal size SiCp/AZ91 magnesium matrix composite with processing map. Mater. Des. 64, 177 (2014).

S.S. Zhou, K.K. Deng, J.C. Li, S.J. Shang, W. Liang, and J.F. Fan: Effects of volume ratio on the microstructure and mechanical properties of particle reinforced magnesium matrix composite. Mater. Des. 63, 672 (2014).

K.B. Nie, K.K. Deng, F.J. Xu, X.J. Wang, and K. Wu: Development of microstructure in submicron particles reinforced magnesium matrix composite processed by room temperature deformation. Mater. Chem. Phys. 149, 21 (2015).

S.Q. Wang, W. Liang, Y. Wang, L.P. Bian, and K.H. Chen: A modified die for equal channel angular pressing. J. Mater. Process. Technol. 209, 3182 (2009).

K.B. Nie, X.J. Wang, K. Wu, L. Xu, M.Y. Zheng, and X.S. Hu: Processing, microstructure and mechanical properties of magnesium matrix nanocomposites fabricated by semisolid stirring assisted ultrasonic vibration. J. Alloys Compd. 509, 8664 (2011).

X.J. Wang, X.S. Hu, K.B. Nie, K. Wu, and M.Y. Zheng: Hot extrusion of SiCp/AZ91 Mg matrix composites. Trans. Nonferrous Met. Soc. China 22, 1912 (2012).

Y.G. Zhao, X.B. Liu, Y.Y. Yang, and T.J. Bian: Effect of SiC particle addition on microstructure of Mg2Si/Al composite. China Foundry 11, 91 (2014).

Z.W. Wang, M. Song, C. Sun, and Y.H. He: Effects of particle size and distribution on the mechanical properties of SiC reinforced Al–Cu Alloy composites. Mater. Sci. Eng., A 528, 1131 (2011).

K. Hagihara, A. Kinoshita, Y. Sugino, M. Yamasaki, Y. Kawamura, H.Y. Yasuda, and Y. Umakoshi: Effect of long-period stacking ordered phase on mechanical properties of Mg97Zn1Y2 extruded alloy. Acta Mater. 58, 6282 (2010).

S.J. Shang, K.K. Deng, K.B. Nie, J.C. Li, S.S. Zhou, F.J. Xu, and J.F. Fan: Microstructure and mechanical properties of SiCp/Mg–Al–Zn composites containing Mg17Al12 phases processed by low-speed extrusion. Mater. Sci. Eng., A 610, 243 (2014).

J.G. Jung, S.H. Park, H. Yu, Y.M. Kim, Y.K. Lee, and B.S. You: Improved mechanical properties of Mg–7.6Al–0.4Zn alloy through aging prior to extrusion. Scr. Mater. 93, 8 (2014).

W. Guo, Q.D. Wang, B. Ye, H. Zhou, and J.F. Liu: Microstructure and mechanical properties of AZ31–Mg2Si in situ composite fabricated by repetitive upsetting. Trans. Nonferrous Met. Soc. China 24, 3755 (2014).

K.B. Nie, X.J. Wang, L. Xu, K. Wu, X.S. Hu, and M.Y. Zheng: Effect of hot extrusion on microstructures and mechanical properties of SiC nanoparticles reinforced magnesium matrix composite. J. Alloys Compd. 512, 355 (2012).

A. Sanaty-Zadeh: Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect. Mater. Sci. Eng., A 531, 112 (2012).

C.Y. Lin, H.J. Tsai, C.G. Chao, and T.F. Liu: Effects of equal channel angular extrusion on the microstructure and high-temperature mechanical properties of ZA85 magnesium alloy. J. Alloys Compd. 530, 48 (2012).

ACKNOWLEDGMENTS

The authors are grateful for financial support received from the National Natural Science Foundation of China (51301118, 51404166); International Cooperation in Shanxi (2014081002); Technological Innovation Programs of Higher Education Institutions in Shanxi (2013108).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Wang, H., Liu, Y. et al. Effect of SiC nanoparticles addition on the microstructures and mechanical properties of ECAPed Mg9Al–1Si alloy. Journal of Materials Research 32, 615–623 (2017). https://doi.org/10.1557/jmr.2016.514

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.514