Abstract

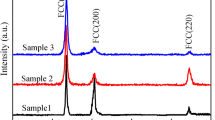

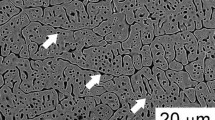

A CoCrFeNiMn high-entropy alloy (HEA), in the form of a face-centered cubic (fcc) solid solution, was processed by high-pressure torsion (HPT) to produce a nanocrystalline (nc) HEA. Significant grain refinement was achieved from the very early stage of HPT through 1/4 turn and an nc structure with an average grain size of ∼40 nm was successfully attained after 2 turns. The feasibility of significant microstructural changes was attributed to the occurrence of accelerated atomic diffusivity under the torsional stress during HPT. Nanoindentation experiments showed that the hardness increased significantly in the nc HEA during HPT processing and this was associated with additional grain refinement. The estimated values of the strain-rate sensitivity were maintained reasonably constant from the as-cast condition to the nc alloy after HPT through 2 turns, thereby demonstrating a preservation of plasticity in the HEA. In addition, a calculation of the activation volume suggested that the grain boundaries play an important role in the plastic deformation of the nc HEA where the flow mechanism is consistent with other nc metals. Transmission electron microscopy showed that, unlike conventional fcc nc metals, the nc HEA exhibits excellent microstructural stability under severe stress conditions.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng., A 375, 213 (2004).

J-W. Yeh, S-K. Chen, S-J. Lin, J-Y. Gan, T-S. Chin, T-T. Shun, C-H. Tsau, and S-Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu: Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1 (2014).

B.S. Murty, J.W. Yeh, and S. Ranganathan: High-Entropy Alloys (Butterworth-Heinemann, London, UK, 2014).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu: Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 62, 105 (2014).

M.A. Hemphill, T. Yuan, G.Y. Wang, J.W. Yeh, C.W. Tsai, A. Chuang, and P.K. Liaw: Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys. Acta Mater. 60, 5723 (2012).

O.N. Senkov, J. Scott, and S. Senkova: Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J. Mater. Sci. 47, 4062 (2012).

C. Zhu, Z.P. Lu, and T.G. Nieh: Incipient plasticity and dislocation nucleation of FeCoCrNiMn high-entropy alloy. Acta Mater. 61, 2993 (2013).

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E.P. George: The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 61, 5743 (2013).

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, and Z.P. Lu: Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 68, 526 (2013).

Y. Wu, W.H. Liu, X.L. Wang, D. Ma, A.D. Stoica, T.G. Nieh, Z.B. He, and Z.P. Lu: In-situ neutron diffraction study of deformation behavior of a multi-component high-entropy alloy. Appl. Phys. Lett. 104, 051910 (2014).

G. Laplanche, P. Gadaud, O. Horst, F. Otto, G. Eggeler, and E.P. George: Temperature dependencies of the elastic moduli and thermal expansion coefficient of an equiatomic, single-phase CoCrFeMnNi high-entropy alloy. J. Alloys Compd. 623, 348 (2015).

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Z. Fu: Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics 56, 24 (2015).

N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, S. Zherebtsov, A. Efimov, and G. Salishchev: Effect of cryo-deformation on structure and properties of CoCrFeNiMn high-entropy alloy. Intermetallics 59, 8 (2015).

H. Gleiter: Nanocrystalline materials. Prog. Mater. Sci. 33, 223 (1989).

R. Valiev: Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 3, 511 (2004).

M.A. Meyer, A. Mishra, and D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427 (2006).

M. Dao, L. Lu, R.J. Asaro, J.T.M. De Hosson, and E. Ma: Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 55, 4041 (2007).

T. Zhu and J. Li: Ultra-strength materials. Prog. Mater. Sci. 55, 710 (2010).

I-C. Choi, Y-J. Kim, M-Y. Seok, B-G. Yoo, J-Y. Kim, Y. Wang, and J-I. Jang: Nanoscale room temperature creep of nanocrystalline nickel pillars at low stresses. Int. J. Plast. 41, 53 (2013).

Y. Ma, G.J. Peng, D.H. Wen, and T.H. Zhang: Nanoindentation creep behavior in a CoCrFeCuNi high-entropy alloy film with two different structure states. Mater. Sci. Eng., A 621, 111 (2015).

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, J. Shi, W.M. Wang, H. Wang, Y.C. Wang, and Q.J. Zhang: Nanocrystalline CoCrFeNiCuAl high-entropy solid solution synthesized by mechanical alloying. J. Alloys Compd. 485, 31 (2009).

S. Varalakshmi, M. Kamaraj, and B.S. Murty: Processing and properties of nanocrystalline CuNiCoZnAlTi high entropy alloys by mechanical alloying. Mater. Sci. Eng., A 527, 1027–1030 (2010).

S. Praveen, B.S. Murty, and S. Kottada Ravi: Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng., A 534, 83 (2012).

R.Z. Valiev and T.G. Langdon: Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 51, 881 (2006).

A.P. Zhilyaev and T.G. Langdon: Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 53, 893 (2008).

T.G. Langdon: Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 61, 7035 (2013).

Q.H. Tang, Y. Huang, Y.Y. Huang, X.Z. Liao, T.G. Langdon, and P.Q. Dai: Hardening of an Al0.3CoCrFeNi high entropy alloy via high-pressure torsion and thermal annealing. Mater. Lett. 151, 126 (2015).

A.P. Zhilyaev, B.K. Kim, G.V. Nurislamova, M.D. Baró, J.A. Szpunar, and T.G. Langdon: Orientation imaging microscopy of ultrafine-grained nickel. Scr. Mater. 46, 575 (2002).

A.P. Zhilyaev, G.V. Nurislamova, B.K. Kim, M.D. Baró, J.A. Szpunar, and T.G. Langdon: Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion. Acta Mater. 51, 753 (2003).

J. Wongsa-Ngam, M. Kawasaki, and T.G. Langdon: A comparison of microstructures and mechanical properties in a Cu–Zr alloy processed using different SPD techniques. J. Mater. Sci. 48, 4653 (2013).

R.Z. Valiev, Y.V. Ivanisenko, E.F. Rauch, and B. Baudelet: Structure and deformaton behaviour of Armco iron subjected to severe plastic deformation. Acta Mater. 44, 4705 (1996).

R.B. Figueiredo, P.R. Cetlin, and T.G. Langdon: Using finite element modeling to examine the flow processes in quasi-constrained high-pressure torsion. Mater. Sci. Eng., A 528, 8198 (2011).

R.B. Figueiredo, P.H.R. Pereira, M.T.P. Aguilar, P.R. Cetlin, and T.G. Langdon: Using finite element modeling to examine the temperature distribution in quasi-constrained high-pressure torsion. Acta Mater. 60, 3190 (2012).

B.N. Lucas and W.C. Oliver: Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 30A, 601 (1999).

M. Kawasaki and T.G. Langdon: The significance of strain reversals during processing by high-pressure torsion. Mater. Sci. Eng., A 498, 341 (2008).

M. Kawasaki: Different models of hardness evolution in ultrafine-grained materials processed by high-pressure torsion. J. Mater. Sci. 49, 18 (2014).

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, and O.N. Senkov: Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J. Alloys Compd. 591, 11 (2014).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

I-C. Choi, D-H. Lee, B. Ahn, K. Durst, M. Kawasaki, T.G. Langdon, and J-I. Jang: Enhancement of strain-rate sensitivity and shear yield strength of a magnesium alloy processed by high-pressure torsion. Scr. Mater. 94, 44 (2015).

I-C. Choi, Y-J. Kim, B. Ahn, M. Kawasaki, T.G. Langdon, and J-I. Jang: Evolution of plasticity, strain-rate sensitivity and the underlying deformation mechanism in Zn–22% Al during high-pressure torsion. Scr. Mater. 75, 102 (2014).

K-Y. Tsai, M-H. Tsai, and J-W. Yeh: Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 61, 4887 (2013).

S-Y. Chang, C-E. Li, Y-C. Huang, H-F. Hsu, J-W. Yeh, and S-J. Lin: Structural and thermodynamic factors of suppressed interdiffusion kinetics in multi-component high-entropy materials. Sci. Reports 4, 4162 (2014).

P.P. Bhattacharjee, G.D. Sathiara, M. Zaid, J.R. Gatti, C. Lee, C-W. Tsai, and J-W. Yeh: Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloy. J. Alloys Compd. 587, 544 (2014).

Y. Amouyal, S.V. Divinski, Y. Estrin, and E. Rabkin: Short-circuit diffusion in an ultrafine-grained copper–zirconium alloy produced by equal channel angular pressing. Acta Mater. 55, 5968 (2007).

S.V. Divinski, J. Ribbe, D. Baither, G. Schmitz, G. Reglitz, H. Rösner, K. Sato, Y. Estrin, and G. Wilde: Nano- and micro-scale free volume in ultrafine grained Cu–1 wt.% Pb alloy deformed by equal channel angular pressing. Acta Mater. 57, 5706 (2009).

S.V. Divinski, J. Ribbe, G. Reglitz, Y. Estrin, and G. Wilde: Percolating network of ultrafast transport channels in severely deformed nanocrystalline metals. J. Appl. Phys. 106, 063502 (2009).

S.V. Divinski, G. Reglitz, H. Rösner, Y. Estrin, and G. Wilde: Ultra-fast diffusion channels in pure Ni severely deformed by equal-channel angular pressing. Acta Mater. 59, 1974 (2011).

K. Oh-ishi, K. Edalati, H-S. Kim, K. Hono, and Z. Horita: High-pressure torsion for enhanced atomic diffusion and promoting solid-state reactions in the aluminum–copper system. Acta Mater. 61, 3482 (2013).

B. Ahn, A.P. Zhilyaev, H-J. Lee, M. Kawasaki, and T.G. Langdon: Rapid synthesis of an extra hard metal matrix nanocomposite at ambient temperature. Mater. Sci. Eng., A 635, 109 (2015).

Y. Minamino, T. Yamane, and A. Shimomura: Effect of high pressure on interdiffusion in an Al-Mg alloy. J. Mater. Sci. 18, 2679 (1983).

K. Edalati, R. Miresmaeili, Z. Horita, H. Kanayama, and R. Pippan: Significance of temperature increase in processing by high-pressure torsion. Mater. Sci. Eng., A 528, 7301 (2011).

P.H.R. Pereira, R.B. Figueiredo, Y. Huang, P.R. Cetlin, and T.G. Langdon: Modeling the temperature rise in high-pressure torsion. Mater. Sci. Eng., A 593, 185 (2014).

H-S. Kim: Finite element analysis of high pressure torsion processing. J. Mater. Process. Technol. 113, 617 (2001).

I-C. Choi, Y-J. Kim, Y.M. Wang, U. Ramamurty, and J-I. Jang: Nanoindentation behavior of nanotwinned Cu: Influences of indenter angle on hardness, strain rate sensitivity and activation volume. Acta Mater. 61, 7313 (2013).

S. Shim, J-I. Jang, and G.M. Pharr: Extraction of flow properties of single crystal silicon carbide by nanoindentation and finite element simulation. Acta Mater. 56, 3824 (2008).

C.L. Wang, Y.H. Lai, J.C. Huang, and T.G. Nieh: Creep of nanocrystalline nickel: A direct comparison between uniaxial and nanoindentation creep. Scr. Mater. 62, 175 (2010).

F. Dalla Torre, P. Spätig, R. Schäublin, and M. Victoria: Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 53, 2337 (2005).

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, and S. Suresh: Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 51, 5159 (2003).

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma: Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater. Sci. Eng., A 381, 71 (2004).

J. Chen, L. Lu, and K. Lu: Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 54, 1913 (2006).

Y.M. Wang, A.V. Hamza, and E. Ma: Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni. Acta Mater. 54, 2715 (2006).

T. Zhu, J. Li, A. Samanta, H-G. Kim, and S. Suresh: Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proc. Natl. Acad. Sci. USA 104, 3031 (2007).

H. Conrad: Grain size dependence of the plastic deformation kinetics in Cu. Mater. Sci. Eng., A 341, 216 (2003).

H. Conard: Plastic deformation kinetics in nanocrystalline FCC metals based on the pile-up of dislocations. Nanotechnology 18, 325701 (2007).

H.J. Frost and M.F. Ashby: Deformation-Mechanism Maps (Pergamon Press, Oxford, 1982).

Z. Wu, H. Bei, G.M. Pharr, and E.P. George: Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 81, 428 (2014).

E. Ma: Watching the nanograins roll. Science 305, 623 (2004).

R.J. Asaro and S. Suresh: Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater. 53, 3369 (2005).

D. Wu, J. Zhang, J.C. Huang, H. Bei, and T.G. Nieh: Grain-boundary strengthening in nanocrystalline chromium and the Hall–Petch coefficient of body-centered cubic metals. Scr. Mater. 68, 118 (2013).

M. Jin, A.M. Minor, E.A. Stach, and J.W. Morris: Direct observation of deformation-induced grain growth during the nanoindentation of ultrafine-grained Al at room temperature. Acta Mater. 52, 5381 (2004).

K. Zhang, J.R. Weertman, and J.A. Eastman: The influence of time, temperature, and grain size on indentation creep in high-purity nanocrystalline and ultrafine grain copper. Appl. Phys. Lett. 85, 5197 (2004).

K. Zhang, J.R. Weertman, and J.A. Eastman: Rapid stress-driven grain coarsening in nanocrystalline Cu at ambient and cryogenic temperatures. Appl. Phys. Lett. 87, 061921 (2005).

X.Z. Liao, A.R. Kilmametov, R.Z. Valiev, H. Gao, X. Li, A.K. Mukherjee, J.F. Bingert, and Y.T. Zhu: High-pressure torsion-induced grain growth in electrodeposited nanocrystalline Ni. Appl. Phys. Lett. 88, 021909 (2006).

ACKNOWLEDGMENTS

The research of JIJ and DHL was supported in part by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (No. 2013R1A1A2A10058551), and in part by the Human Resources Development program of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government (MOTIE) (No. 20134030200360). The work of MK was supported in part by the NRF Korea funded by MoE under Grant No. NRF-2014R1A1A2057697. The work of TGL was supported by the National Science Foundation of the United States under Grant No. DMR-1160966 and by the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lee, DH., Choi, IC., Seok, MY. et al. Nanomechanical behavior and structural stability of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Journal of Materials Research 30, 2804–2815 (2015). https://doi.org/10.1557/jmr.2015.239

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.239