Abstract

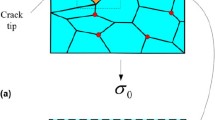

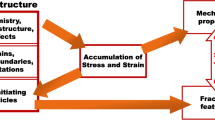

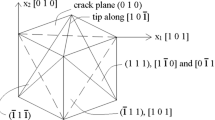

A combined dislocation–cohesive zone model was proposed to describe the fracture toughness of nanocrystalline (nc) materials. In the framework of the model, cohesive stress near crack tip initiates edge dislocations, which move to the opposite grain boundaries. The emitted dislocations provide a shielding effect of the crack. The dependence of both the maximum number of dislocations, emitted by a crack, and the critical stress intensity factor on grain size d (ranging from 20 to100 nm) for Cu was calculated. The calculated results show that (i) nc materials have low fracture toughness, (ii) the critical stress intensity factor decreases with decreased grain size, and (iii) the grain size effect is not high; for instance, increasing the grain size from 20 to 100 nm increases the value of critical stress intensity factor only by 0.035 MPa/m1/2.

Similar content being viewed by others

REFERENCES

M.A. Meyers, A. Mishra, and D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427 (2006).

T.D. Shen, C.C. Koch, T.Y. Tsui, and G.M. Pharr: On the elastic moduli of nanocrystalline Fe, Cu, Ni, and Cu–Ni alloys prepared by mechanical milling/alloying. J. Mater. Res. 10, 2892 (1995).

K.S. Kumar, S. Suresh, and H. Van Swygenhoven: Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 51, 5743 (2003).

C.C. Koch: Structural nanocrystalline materials: An overview. J. Mater. Sci. 42, 1403 (2007).

L. Lu, L.B. Wang, B.Z. Ding, and K. Lu: High-tensile ductility in nanocrystalline copper. J. Mater. Res. 15, 270 (2000).

M. Dao, L. Lu, R.J. Asaro, J.T.M. De Hosson, and E. Ma: Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 55, 4041 (2007).

Y.G. Liu, J.Q. Zhou, T.D. Shen, and D. Hui: Effects of ultrafine nanograins on the fracture toughness of nanocrystalline materials. J. Mater. Res. 26, 1734 (2011).

Y.G. Liu, J.Q. Zhou, and X. Ling: Impact of grain size distribution on the multiscale mechanical behavior of nanocrystalline materials. Mater. Sci. Eng., A 527, 1719 (2010).

B. Jiang and G.J. Weng: A generalized self-consistent polycrystal model for the yield strength of nanocrystalline materials. J. Mech. Phys. Solids 52, 1125 (2004).

I.A. Ovid’ko: Review on the fracture processes in nanocrystalline materials. J. Mater. Sci. 42, 1694 (2007).

J.D. Kuntz, G.D. Zhan, and A.K. Mukherjee: Nanocrystalline-matrix ceramic composite for improved fracture toughness. MRS Bull. 29, 22 (2004).

Y. Zhao, J. Qian, L.L. Daemen, C. Pantea, J. Zhang, G.A. Voronin, and T.W. Zerda: Enhancement of fracture toughness in nanostructured diamond–SiC composites. Appl. Phys. Lett. 84, 1356 (2004).

Y.T. Pei, D. Galvan, and J.T.M. De Hosson: Nanostructure and properties of TiC/a-C: H composite coatings. Acta Mater. 53, 4505 (2005).

A. Singh, L. Tang, M. Dao, L. Lu, and S. Suresh: Fracture toughness and fatigue crack growth characteristics of nanotwinned copper. Acta Mater. 59, 2437 (2011).

A. Singh, L. Tang, M. Dao, L. Lu, and S. Suresh: Enhanced fracture toughness and strength in bulk nanocrystalline Cu with nanoscale twin bundles. Acta Mater. 57, 6215 (2009).

R. Mirshams, S.H. Whang, C.H. Xiao, and W.M. Yin: R-curve characterization of the fracture toughness of nanocrystalline nickel thin sheets. Mater. Sci. Eng., A 315, 21 (2001).

M.Y. Gutkin and I.A. Ovid’ko: Homogeneous nucleation of dislocation loops in nanocrystalline metals and ceramics. Acta Mater. 56, 1642 (2008).

S.V. Bobylev, A.K. Mukherjee, I.A. Ovid’ko, and A.G. Sheinerman: Effects of intergrain sliding on crack growth in nanocrystalline materials. Int. J. Plast. 26, 1629 (2010).

I.A. Ovid’ko and A.G. Sheinerman: Ductile vs. brittle behavior of pre-cracked nanocrystalline and ultrafine-grained materials. Acta Mater. 58, 5286 (2010).

Y.G. Liu, J.Q. Zhou, L. Wang, S. Zhang, and Y. Wang: Grain size dependent fracture toughness of nanocrystalline materials. Mater. Sci. Eng., A 528, 4615 (2011).

S.V. Bobylev, N.F. Morozov, and I.A. Ovid’ko: Cooperative grain boundary sliding and migration process in nanocrystalline solids. Phys. Rev. Lett. 105, 055504 (2010).

N.F. Morozov, I.A. Ovid’ko, A.G. Sheinerman, and E.C. Aifantis: Special rotational deformation as a toughening mechanism in nanocrystalline solids. J. Mech. Phys. Solids 58, 1088 (2010).

W. Yang and H.T. Wang: Brittle versus ductile transition of nanocrystalline metals. Int. J. Solids Struct. 45, 3897 (2008).

F. Yang and W. Yang: Crack growth versus blunting in nanocrystalline metals with extremely small grain size. J. Mech. Phys. Solids 57, 305 (2009).

A. Needleman: A continuum model for void nucleation by inclusion debonding. J. Appl. Mech. 54, 525 (1987).

V. Tvergaard and J.W. Hutchinson: The relation between crack growth resistance and fracture process parameters in elastic–plastic solids. J. Mech. Phys. Solids 40, 1377 (1992).

V. Tvergaard and J.W. Hutchinson: The influence of plasticity on mixed mode interface toughness. J. Mech. Phys. Solids 41, 1119 (1993).

V. Tvergaard and J.W. Hutchinson: On the toughness of ductile adhesive joints. J. Mech. Phys. Solids 44, 789 (1996).

H.H.M. Cleveringa, E. van der Giessen, and A. Needleman: A discrete dislocation analysis of mode-I crack growth. J. Mech. Phys. Solids 48, 1133 (2000).

M.P. O’Day and W.A. Curtin: Bimaterial interface fracture: A discrete dislocation model. J. Mech. Phys. Solids 53, 359 (2005).

A.G. Chng, M.P. O’Day, W.A. Curtin, A.A.O. Tay, and K.M. Lim: Fracture in confined thin films: A discrete dislocation study. Acta Mater. 54, 1017 (2006).

N.G. Broedling, A. Hartmaier, and H.J. Gao: A combined dislocation–cohesive zone model for fracture in a confined ductile layer. Int. J. Fract. 140, 169 (2006).

N.G. Broedling, A. Hartmaier, and H.J. Gao: Fracture toughness of layered structures: Embrittlement due to confinement of plasticity. Eng. Fract. Mech. 75, 3743 (2008).

T.K. Bhandakkar, A.C. Chng, W.A. Curtin, and H.J. Gao: Dislocation shielding of a cohesive crack. J. Mech. Phys. Solids 58, 530 (2010).

V.S. Deshpande, A. Needleman, and E. van der Giessen: A discrete dislocation analysis of near-threshold fatigue crack growth. Acta Mater. 49, 3189 (2001).

V.S. Deshpande, A. Needleman, and E. van der Giessen: Discrete dislocation modeling of fatigue-crack propagation. Acta Mater. 50, 831 (2002).

D.S. Dugdale: Yielding of steel sheets containing slits. J. Mech. Phys. Solids 8, 100 (1960).

N. Chandra, H. Li, C. Shet, and H. Ghonem: Some issues in the application of cohesive zone models for metal–ceramic interfaces. Int. J. Solids Struct. 39, 2827 (2002).

I. Scheider, M. Rajendran, and A. Banerjee: Comparison of different stress-state dependent cohesive zone models applied to thin-walled structures. Eng. Fract. Mech. 78, 534 (2011).

A.H. Chokshi, A. Rosen, J. Karch, and H. Gleiter: On the validity of the Hall–Petch relationship in nanocrystalline materials. Scr. Metall. Mater. 23, 1679 (1989).

D.K. Kim and K. Okazaki: Processing of superconducting composite materials by electro-discharge compaction. Mater. Sci. Forum 88, 553 (1992).

T.D. Shen, R.B. Schwarz, S. Feng, J.G. Swadener, J.Y. Huang, M. Tang, J.Z. Zhang, S.C. Vogel, and Y.S. Zhao: Effect of solute segregation on the strength of nanocrystalline alloys: Inverse Hall–Petch relation. Acta Mater. 55, 5007 (2007).

G. Palumbo, U. Erb, and K.T. Aust: Triple line disclination effects on the mechanical behaviour of materials. Scr. Metall. Mater. 24, 2347 (1990).

T.Y. Zhang and J.C.M. Li: Image forces and shielding effects of an edge dislocation near a finite length crack. Acta Metall. Mater. 39, 2739 (1991).

I.H. Lin and R. Thomson: Cleavage, dislocation emission, and shielding for cracks under general loading. Acta Metall. 34, 187 (1986).

I.A. Ovid’ko: Deformation and diffusion modes in nanocrystalline materials. Int. Mater. Rev. 50, 65 (2005).

Y.G. Liu, J.Q. Zhou, T.D. Shen, and D. Hui: Grain rotation dependent fracture toughness of nanocrystalline materials. Mater. Sci. Eng., A 528, 7684 (2011).

H. Li and F. Ebrahimi: Transition of deformation and fracture behaviors in nanostructured face-centered-cubic metals. Appl. Phys. Lett. 84, 4307 (2004).

H. Li and F. Ebrahimi: Ductile-to-brittle transition in nanocrystalline metals. Adv. Mater. 17, 1969 (2005).

F. Ebrahimi, A.J. Liscano, D. Kong, Q. Zhai, and H. Li: Fracture of bulk face centered cubic metallic nanostructures. Rev. Adv. Mater. Sci. 13, 33 (2006).

ACKNOWLEDGMENTS

The authors are grateful for the funding of the National Natural Science Foundation of China (10502025 and 10872087), Natural Science Foundation of Jiangsu Province (BK2007528), Key Project of Chinese Ministry of Education (211061), Natural Science Foundation of Hubei Province, and Research and Innovation Projects Foundation of University Postgraduate of Jiangsu Province (CX10B_167Z).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Zhou, J. & Shen, T. A combined dislocation–cohesive zone model for fracture in nanocrystalline materials. Journal of Materials Research 27, 694–700 (2012). https://doi.org/10.1557/jmr.2011.442

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.442