Abstract

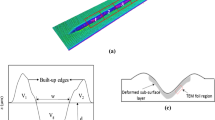

An iron aluminide (Fe–40 at.% Al) was thermal oxidation (TO)-treated at 1000 °C for 30 to 150 h. The mechanical properties (e.g., hardness and elastic modulus), the scratch resistance, the deformation and damage behaviors of the TO-treated surface layers were evaluated using nanoindentation and nanoscratch techniques. It has been found that the TO treatment produced an oxide layer containing α–Al2O3 on the iron aluminide surface, which increased the surface hardness (H) and elastic modulus (Er) but reduced the ratio of Er/H. This has significantly improved the scratch resistance of the iron aluminide. Longer treatment resulted in a thicker oxide layer and led to further reduced scratch rate and an increased critical load to failure. The scratch resistance has been correlated with the scratch load, the hardness, and the Er/H ratio of the surface oxide layer.

Similar content being viewed by others

References

N.S. Stoloff, in High Temperature Ordered Intermetallic Alloys, edited by C.C. Koch, C.T. Liu, and N.S. Stoloff (Mater. Res. Soc. Symp. Proc. 39, Pittsburgh, PA, 1985), p. 3.

J.R. Stephens, in High Temperature Ordered Intermetallic Alloys, edited by C.C. Koch, C.T. Liu, and N.S. Stoloff (Mater. Res. Soc. Symp. Proc. 39, Pittsburgh, PA, 1985), p. 395.

C.T. Liu, E.P. George, P.J. Maziasz, and J.H. Schneibel, Mater. Sci. Eng. A 258, 84 (1998).

Y.S. Kim and Y.H Kim, Mater. Sci. Eng. A 258, 319 (1998).

J.A. Hawk and D.E. Alman, Mater. Sci. Eng. A 239–240, 899 (1997).

H.E. Maupin, R.D. Wilson, and J.A. Hawl, Wear 162-164, 432 (1993).

X.S. Guan, S.M. Zhu, K. Shibata, and K. Iwasaki, Mater. Trans. 43, 1325 (2002).

D.E. Alman, J.A. Hawk, J.H. Tylczak, C.P. Doğan, and R.D. Wilson, Wear 251, 875 (2001).

H. Dong and T. Bell, Wear 238, 131 (2000).

I.J. McColm, Ceramic Hardness (Plenum Press, New York, 1990), p. 259.

B.A. Pint, P.F. Tortorelli, and I.G. Wright, in Oxidation of Intermetallics, edited by H.J. Grabke and M. Schütze (Wiley-VCH, New York, 1997), p. 183.

M.A. Montealegre, J.L. González-Carrasco, M.A. Muñoz-Morris, J. Chao, and D.G. Morris, Intermetallics 8, 439 (2000).

J. Xia, C.X. Li, and H. Dong, Mater. Sci. Eng. A 354, 112 (2003).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

I.M. Hutchings, Tribology: Friction and Wear of Engineering Materials (Edward Arnold, London, 1992), p. 150.

I.M. Hutchings, Tribology: Friction and Wear of Engineering Materials (Edward Arnold, London, 1992), p. 83.

B. Bhushan, Wear 251, 1105 (2001).

J.A. Greenwood and J.B.P. Williamson, Proc. R. Soc. (London) A 295, 300 (1966).

I.M. Hutchings, Tribology: Friction and Wear of Engineering Materials (Edward Arnold, London, 1992), p. 20.

A. Leyland and A. Matthews, Wear 246, 1 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, J., Li, C.X., Dong, H. et al. Nanoindentation and nanoscratch of a thermal oxide layer on a FeAl alloy. Journal of Materials Research 19, 291–300 (2004). https://doi.org/10.1557/jmr.2004.19.1.291

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2004.19.1.291