Abstract

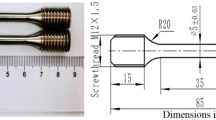

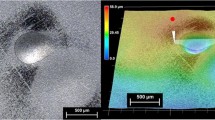

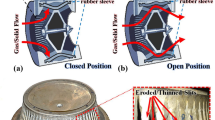

The bimetallic valves were produced using a new technique, IFFM (Impact Fused-Forging Modeling). Distribution of the alloy components as well as phase composition across the valve section was obtained by means of energy-dispersive analysis and X-ray diffraction. Optic and electron microscopy research of macro- and microstructure was conducted. High quality of the joint between the sintermetallic (TiAl) head and the titanium (VT-9 and VT-6 alloys) stem was demonstrated. As a result of the contact of the stem with the semi-solid intermetallics at the temperature above Tc, a polymorphous transformation was obtained in the upper part of the Ti-based stem. The globular microstructure in the intermetallic head in the area near to the joint of the two alloys was achieved. The results proved that the process allows production of complex shaped parts based on advanced alloys of high quality, featuring extra wear-resistance and strength.

Similar content being viewed by others

References

T.-S. Shen, J. Am. Ceram. Soc., 77(9), 2345 (1994).

E. Paransky, E.Y. Gutmanas, J. Gotman and M. Koczak, J. Metal. and Mater. A, 27A, 2130 (1996).

Tianyi Cheng, M. McLean, J. Mater. Sci, 32, 6255 (1996).

D.E. Larsen, D.A. Wheeler and B. London, in Recent Developments in Investment Cast Processing, Properties and Applications for Gamma Titanium Aluminides Alloy (Proc. of the Seventh World Titanium Conf., June 1992, San Diego, California, 1992) pp. 1487–1493.

P.E. Jones, W.J. Porter, D. Eylon and G. Golvin, in Abstract Booklet of the 124th TMS Annual Meeting and Exhibition, Feb. 1995, Las Vegas, Nevada 1995) p. 15.

S. Hurta, H. Clemens, G. Frommeyer, H. -P. Nikolai and H. Sabum, in Valves of Intermetallic g-TiAl Base Alloys: Processing and Properties, (Abstract Booklet of The Eighth World Conference on Titanium, Birmingham 1995), p. S 3a/3; P.E. Jones, D. Eylon and G. Golvin, ibid. p. S 6a/2.

B.N. Kodess, M.T. Medetbekov, The Distribution of Phases, Composition and Properties of Ti-Al Alloys after various perturbation Action), VNIIMS, GosStandart of Russia 14.05.96, Depozit VINITI No. 3137-B96, 1996), pp. 45

G.P. Teterin, A.E. Volkov, Kuznechn.-Shtampov. Proizvodstvo (Forging and Stamping Production. Material Working by Pressure), 7, 2 (1994).

A.E. Volkov, G.P. Teterin, Vestnik Mashinostr., 12, 43 (1995)

B.N. Kodess, presented at the 1995 MRS Fall Meeting, Boston, MA, C222; G. G. Sadikov, L.A.Butman, B.N. Kodess, ibid. 1993, F101 (unpublished).

G.P. Teterin, B.N. Kodess, S.M. Zivotov in Theory, Technology and Equipment of Stamping Production, edited by A.S. Sergeev, Tula, 1996) pp. 134–138.

A. Volkov, RU Patent No. 2009011 (4 February 1992).

L.A. Kommel, G.P. Teterin, B.N. Kodess, Kuznechno-Shtamp. Proizv. (Forging and Stamping Production. Material Working by Pressure) 7, 29 (1998).

V.I. Panin, Y.V. Burakov, N.D. Chainov, D.B. Lukin, A.E. Volkov, presented at the 1997 SETC, Yokogama, Okt. 3, Japan, Presentations No. 123 (unpublished).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kodess, B.N., Teterin, G.P., Kommel, L.A. et al. Structure and Mechanical Properties of the Engine Valves with Intermetallic Disk. MRS Online Proceedings Library 552, 8371 (1998). https://doi.org/10.1557/PROC-552-KK8.37.1

Published:

DOI: https://doi.org/10.1557/PROC-552-KK8.37.1