Abstract

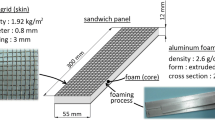

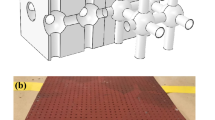

The feasibility of complex shaped aluminum foam parts as permanent cores in aluminum castings has been investigated. The foamed samples were prepared by injection of the foam into sand molds. It turned out that sound castings can be produced if the foam core is properly preheated and/or surface treated before casting. The effect of the foam core on the performance of the casting was evaluated by in compression testing and by measuring structural damping. The gain in the related properties turned out to be much higher than the weight increase of the casting due to the presence of the core. The weight increase may be partially offset through a reduction of the wall-thickness of the shell.

Similar content being viewed by others

References

F. Simandik, J. Kováčik and F. Schoerghuber in Metalschäume. edited by J. Banhart (Proc. Symposium Metallschäume Bremen, 6.-7.3. 1997) pp. 171–176.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Simančík, F., Schoerghuber, F. Complex Foamed Aluminum Parts as Permanent Cores in Aluminum Castings. MRS Online Proceedings Library 521, 151–157 (1998). https://doi.org/10.1557/PROC-521-151

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-521-151