Abstract

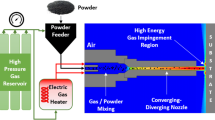

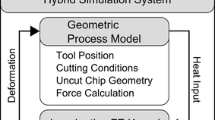

A nonlinear dynamic model of the chemical vapor deposition (CVD) process has been developed and analyzed to obtain insight into the design of an appropriate control structure.

CVD's importance is related in part to the possibility of engineering the micro-structure of the coatings which determines coating properties. Our ultimate research objective is to develop a system to control the micro-structure of coatings produced by CVD based on in-situ measurements related to the growth process. The conventional practice is to regulate the inputs in a feedforward manner (i.e. maintaining temperature, pressure and gas flow rates set-points), and only limited work has been directed at developing control strategies to ensure that a desired micro-structure is achieved. Development of a measurement-based feedback system can enhance the ability to achieve coating microstructure, compensate for process variations (disturbances) and improve the capability of transferring process recipes to different systems. However, successful development of an appropriate control structure (i.e. selection and connection of measurements to specific inputs) requires an explicit understanding of the process dynamics.

Extensive modelling and experimental investigations have considered the fluid/thermal/chemical nature of CVD, but most of this work has focused on the steady-state characteristics of the system [1, 2, 3, 4, 5]. To obtain insight into an appropriate control structure, we have developed a lumped, dynamic, nonlinear process model that relates the manipulable inputs to the local thermal/fluid behavior of the equipment and, in turn, to the physics of the deposition process [6, 7]. As a bench- mark, we focus on TiN deposition since there has been significant experimental work reported and is an important coating for cutting tools. Specific features addressed in this paper are the transport delay and multicomponent aspect of the deposition process. An experimental CVD unit is being developed that is the basis for the physical parameters used in this analysis.

Similar content being viewed by others

References

D.I. Fotiadis, {etet al.}, Journal of Crystal Growth, v. 100, 577–599, 1990.

K.E. Spear, Proc. of the 51h European Conference on CVD, 1985.

F. Ulacia, S. Howell, H. Korner, and C. Werner, Applied Surface Science, v. 38, 370–385,1989.

N. Nakanishi, S. Mori, and E. Kato, J. Electrochem. Soc., v. 137, n. 1, 322–328, 1990.

J.P. Dekker, {etet al.}, J. Electrochem Soc., Vol. 141, No. 3, p. 787, 1994.

M.A. Gevelber {etet al.}, submitted to the Journal of Dynamic Syst., Meas. and Control, Sept. 1993, appears in ACC Conference Proceedings June 1994, p 2623.

M.A. Gevelber, M. Toledo-Quifiones, and M. Bufano, in the Proceedings of the 1994 Japan-USA Symposium on Flexible Automation, Kobe Japan, July 1994, p 1417.

M.S. You, N. Nakanishi, and E. Kato, J. Electrochem. Soc., Vol. 138, No. 5, 1991, p 1394.

R.B. Bird, W.E. Stewart, and W.N. Lightfoot, “Transport Phenomena”, John Wiley & Sons, 1960.

Acknowledgments

We would like to acknowledge the useful discussions with V. Sarin and his research group as well as the financial support from NSF in terms of an equipment grant (DDM 9212792) and more recently a research grant (DMI-9300614).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gevelber, M.A., Quinones, M.T. & Bufano, M.L. Dynamic Modelling of CVD for Real-Time Control of Microstructure. MRS Online Proceedings Library 363, 33–38 (1994). https://doi.org/10.1557/PROC-363-33

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-363-33