Abstract

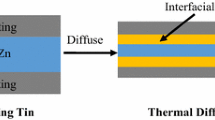

Brazing is a unique method to permanently join a wide range of materials without oxidation. It has wide commercial application in fabricating components. This paper discusses results regarding the brazing process of 304 stainless steel. The experimental brazing is carried out using a nickel-based (Ni-11Cr-3.5Si-2.25B-3.5Fe) filler alloy. In this process, boron and silicon are incorporated to reduce the melting point, however they form hard and brittle intermetallic compounds with nickel (eutectic phases) which are detrimental to the mechanical properties of brazed joints. This investigation deals with the effects of holding time and brazing temperature on the microstructure of joint and base metal, intermetallic phases formation within the brazed joint as well as measurement of the tensile strength . The results show that a maximum tensile strength of 464 MPa is obtained at 1120°C and 4 h holding time. The shortest holding times will make boron diffuse insufficiently and generate a great deal of brittle boride components.

Similar content being viewed by others

References

Y.H. Yu, M.O. Lai. Effect of gap filler and brazing temperature on fracture and fatigue of wide-gap brazed joints. J. Mater. Sci. 30 (1995) 2101–2107.

E. Lugscheider, Th. Schittny, E. Halmoy. Metallurgical aspects of additive-aided wide-clearance brazing with nickel-based filler metals. Welding journal (1989) 9s-13s.

W.D. Zhung, T.W. Eagar. Transient liquid phase bonding using coated metal powders. Welding journal (1997) 157s-162s.

S.K. Tung, L.C. Lim. Wide gap brazing with precraks of nickel base braze mixes. Mater. Sci. Technol. 11 (1995) 949–954.

R. Johnson, M. Baron and N.J. Livesey, Third International Brazing and Soldering Conference (BABS), Paper 21, 1979.

E. Lugsscheider, H. Schmoor, U. Eritt, Brazing, High Temperature Brazing and Diffusion Welding, Deutscher Verlag fur Schweisstechnik GmbH, Germany, 259–261 (1995).

F. Pra, P. Tochon, Ch. Mauget, J. Fokkens and S. Willemsen. Promising designs of compact heat exchangers for modular HTRs using the Brayton cycle. Nuc. Eng. Des. 2008; 238 (11): 3160–3173.

Wenchun Jiang, Jiangming Gong, Shan-Tung Tu, Hu Chen. Effect of geometric conditions on residual stress of brazed stainless steel plate-fin structure. Nuc. Eng. Des. 2008; 238 (7): 1497–1502.

W.F. Gale, E.R. Wallach. Microstructural development in transient liquid-phase bonding. Metall. Trans. A 22 (1991) 2451–2457.

R.D. Eng, E.J. Ryan and J.R. Doyle. Solidification phenomena in nickel base brazes containing boron and silicon. Welding Journal, 56, 15 (1977).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

García-Vázquez, F., Guzmán-Flores, I., Garza, A. et al. Evolution of microstructure of 304 stainless steel joined by brazing process. MRS Online Proceedings Library 1276, 12 (2010). https://doi.org/10.1557/PROC-1276-12

Published:

DOI: https://doi.org/10.1557/PROC-1276-12