Abstract

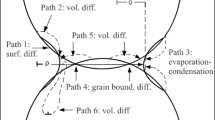

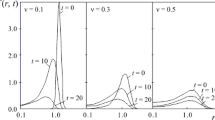

The correlations between coarsening (including grain and pore growth) and densification, and the effects of mass transport on particle coarsening and densification were discussed based on the simple particle array models and for the real particle compacts. Grain boundary motion could cause particle coarsening only under a certain particle size distribution but not densification; mass transport is reasoned to contribute to both grain growth (particle coarsening) and shrinkage for one-dimensional particle arrays. Under a certain limitation for the change of the particle size aspect ratio during sintering, very limited effects of grain grown by itself on the shrinkage of particle a rrays throughreinitiating the sintering could be found. For a real powder compact system, mass transport between the particles, which surround a pore, contributes to the particle coarsening and densification when the pore is thermodynamically unstable and only to particle coarsening when the pore is thermodynamically stable. The mass transport mechanism for both particle coarsening and densification would be the same, which cannot exclude, at least on thermodynamics, the contribution from surface diffusion in the intermediate stage of sintering.

Similar content being viewed by others

References

V. A. Bokov and I. E. Myl’nikova, Sov. Phys. Solid State, 3, 613 (1961).

T.R. Shrout, S.L. Swartz, and M.J. Haun, Am. Ceram. Soc. Bull. 63, 808 (1984).

M. Yonezawa, Ferroelectr. 68, 181 (1986).

M. Furuya, T. Mori, A. Ochi, S. Saito, and S. Takahashi, Jpn. J. Appl. Phys. 31, 3139 (1992).

S. Takahashi, S. Miyao, S. Yoneda, and M. Kuwabara, Jpn. J. Appl. Phys. 32, 4245 (1993).

G. Zhilun, L. Longtu, G. Suhua, and Z. Xiaowen, J. Am. Ceram. Soc. 72, 486 (1989).

G. Zhilun, L. Lingtu, L. Hongqing, and Z. Xiaowen, Ferroelectr. 101, 93 (1990).

N. Ichinose and M. Kimura, Jpn. J. Appl. Phys. 30, 2220 (1991).

J. H. Moon, H. M. Jang, and B. D. You, J. Mater. Res. 8, 3184 (1993).

M. S. Yoon and H. M. Jang, Ferroelectr. 173, 191 (1995).

J. R. Belsick, A. Halliyal, U. Kumer, and R. E. Newnham, Am. Ceram. Soc. Bull. 66, 664 (1987).

R. Vivekanandan and T.R. N. Kutty, Ceram. Int. 14, 207 (1988).

G. A. Rossetti, Jr., D. J. Watson, R.E. Newnham, and J.H. Adair, J. Cryst. Growth 116, 251 (1992).

P. K. Dutta and J. R. Gregg, Chem. Mater. 4, 843 (1992).

H. Cheng, J. Ma, B. Zhu, and Y. Cui, J. Am. Ceram. Soc. 76, 625 (1993).

C. H. Lu and S. Y. Lo, Mater. Res. Bull. 32, 371 (1997).

C. H. Lu and W. J. Hwang, Mater. Lett. 27, 229 (1996).

T.R. Shrout and A. Halliyal, Am. Ceram. Soc. Bull. 66, 704 (1987).

C. H. Lu and W. J. Hwang, Ceram. Int. 22, 373 (1996).

Powder Diffraction File, Card No. 34–103, Joint Committee on Powder Diffraction Standards, Swarthmore, PA.

Powder Diffraction File, Card No. 35–739, Joint Committee on Powder Diffraction Standards, Swarthmore, PA.

K. Uchino, F. Kojima, and S. Nomura, Ferroelectr. 15, 69 (1977).

T. Takenaka, A. S. Bhalla, and L. E. Cross, J. Am. Ceram. Soc. 72, 1016 (1989).

B. P. Blazhievskii, V. A. Isupov, L. V. Kozlovskii, L. I. Mikhailova, V. I. Moskalev, and N. E. Semenov, Inorg. Mater. 22, 418 (1986).

C. H. Lu and W.S. Hwang, J. Mater. Res. 10, 2755 (1995).

C. H. Lu and W.S. Hwang, J. Ceram. Soc. Jpn. 104, 587 (1996).

F. Kuchar and M. W. Valena, Phys. Status Solidi 6, 525 (1971).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Shi, J.L. Relations Between Coarsening and Densification and Mass Transport Path in Solid-state Sintering of Ceramics: Model Analysis. Journal of Materials Research 14, 13 (1999). https://doi.org/10.1557/JMR.1999.0188

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/JMR.1999.0188