Abstract

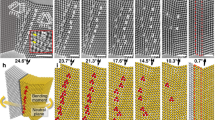

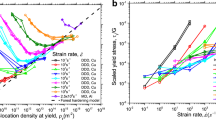

Dislocation-mediated plasticity in stable nanocrystalline metals, where grain boundary motion is suppressed, is revisited in the context of dislocation elastodynamics. The effect of transient waves that emanate from the generation and motion of dislocations is quantified for an idealized Cu–10 at.% Ta system with grain sizes on the order of 50 nanometers. Simulations indicate that for this material, as dislocation velocities approach 0.6–0.8 times the shear wave speed, grains several grain diameters away from the initial glide event experience a large transient shear stress for a finite duration. These transient shear stresses increase with increasing glide velocity and can activate nucleation sites far from the original nucleation event. These considerations are used to explain recent experimental observations of a lack of increase in flow stress with increasing loading rate, as well as localization resistance, in this class of stable nanocrystalline metals.

Similar content being viewed by others

References

E. Orowan: Problems of plastic gliding. Proc. Phys. Soc. 52, 8 (1940).

H. Conrad: Grain size dependence of the plastic deformation kinetics in Cu. Mater. Sci. Eng., A 341, 216–228 (2003).

Q. Wei, S. Cheng, K. Ramesh, and E. Ma: Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater. Sci. Eng., A 381, 71–79 (2004).

A. Argon and S. Yip: The strongest size. Philos. Mag. Lett. 86, 713–720 (2006).

M. Dao, L. Lu, R. Asaro, J.T.M. De Hosson, and E. Ma: Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 55, 4041–4065 (2007).

Y. Wei, A. Bower, and H. Gao: Enhanced strain-rate sensitivity in fcc nanocrystals due to grain-boundary diffusion and sliding. Acta Mater. 56, 1741–1752 (2008).

K. Zhang, J. Weertman, and J. Eastman: Rapid stress-driven grain coarsening in nanocrystalline Cu at ambient and cryogenic temperatures. Appl. Phys. Lett. 87, 061921 (2005).

C. Koch, R. Scattergood, K. Darling, and J. Semones: Stabilization of nanocrystalline grain sizes by solute additions. J. Mater. Sci. 43, 7264–7272 (2008).

K. Darling, A.J. Roberts, Y. Mishin, S.N. Mathaudhu, and L.J. Kecskes: Grain size stabilization of nanocrystalline copper at high temperatures by alloying with tantalum. J. Alloys Compd. 573, 142–150 (2013).

K. Darling, E. Huskins, B. Schuster, Q. Wei, and L. Kecskes: Mechanical properties of a high strength Cu–Ta composite at elevated temperature. Mater. Sci. Eng., A 638, 322–328 (2015).

T. Frolov, K. Darling, L. Kecskes, and Y. Mishin: Stabilization and strengthening of nanocrystalline copper by alloying with tantalum. Acta Mater. 60, 2158–2168 (2012).

R. Koju, K. Darling, K. Solanki, and Y. Mishin: Atomistic modeling of capillary-driven grain boundary motion in Cu–Ta alloys. Acta Mater. 148, 311–319 (2018).

K. Darling, M. Rajagopalan, M. Komarasamy, M. Bhatia, B. Hornbuckle, R. Mishra, and K. Solanki: Extreme creep resistance in a microstructurally stable nanocrystalline alloy. Nature 537, 378 (2016).

G. Regazzoni, U. Kocks, and P. Follansbee: Dislocation kinetics at high strain rates. Acta Metall. 35, 2865–2875 (1987).

S. Turnage, M. Rajagopalan, K. Darling, P. Garg, C. Kale, B. Bazehhour, I. Adlakha, B. Hornbuckle, C. Williams, P. Peralta, and K. Solanki: Anomalous mechanical behavior of nanocrystalline binary alloys under extreme conditions. Nat. Commun. 9, 2699 (2018).

I. Lin, J. Hirth, and E. Hart: Plastic instability in uniaxial tension tests. Acta Metall. 29, 819–827 (1981).

Q. Wei: Strain rate effects in the ultrafine grain and nanocrystalline regimes influence on some constitutive responses. J. Mater. Sci. 42, 1709–1727 (2007).

K. Darling, M. Tschopp, R. Guduru, W. Yin, Q. Wei, and L. Kecskes: Microstructure and mechanical properties of bulk nanostructured Cu–Ta alloys consolidated by equal channel angular extrusion. Acta Mater. 76, 168–185 (2014).

M. Bhatia, M. Rajagopalan, K. Darling, M. Tschopp, and K. Solanki: The role of Ta on twinnability in nanocrystalline Cu–Ta alloys. Mater. Res. Lett. 5, 48–54 (2017).

R. Clifton: On the analysis of elastic/visco-plastic waves of finite uniaxial strain. In Shock Waves and the Mechanical Properties of Solids, J. Burke and V. Weiss, eds. (Syracuse University Press, Syracuse, New York, 1971); pp. 73–116.

U. Kocks, A. Argon, and M. Ashby: Thermodynamics and kinetics of slip. Prog. Mater. Sci. 19, 1–281 (1975).

D. Kuhlmann-Wilsdorf: Theory of plastic deformation: Properties of low energy dislocation structures. Mater. Sci. Eng., A 113, 1–41 (1989).

J. Taylor: Dislocation dynamics and dynamic yielding. J. Appl. Phys. 36, 3146–3150 (1965).

W. Johnston and J. Gilman: Dislocation multiplication in lithium fluoride crystals. J. Appl. Phys. 31, 632–643 (1960).

Y. Gupta, G. Duvall, and G. Fowles: Dislocation mechanisms for stress relaxation in shocked LiF. J. Appl. Phys. 46, 532–546 (1975).

F. Roters, D. Raabe, and G. Gottstein: Work hardening in heterogeneous alloys—A microstructural approach based on three internal state variables. Acta Mater. 48, 4181–4189 (2000).

W. Johnston and J. Gilman: Dislocation velocities, dislocation densities, and plastic flow in lithium fluoride crystals. J. Appl. Phys. 30, 129–144 (1959).

V. Yamakov, D. Wolf, S. Phillpot, A. Mukherjee, and H. Gleiter: Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation. Nat. Mater. 1, 45 (2002).

O. Jones and J. Mote: Shock-induced dynamic yielding in copper single crystals. J. Appl. Phys. 40, 4920–4928 (1969).

J. Johnson, O. Jones, and T. Michaels: Dislocation dynamics and single crystal constitutive relations: Shock-wave propagation and precursor decay. J. Appl. Phys. 41, 2330–2339 (1970).

R. Austin and D. McDowell: A dislocation-based constitutive model for viscoplastic deformation of fcc metals at very high strain rates. Int. J. Plast. 27, 1–24 (2011).

J. Lloyd, J. Clayton, R. Austin, and D. McDowell: Plane wave simulation of elastic-viscoplastic single crystals. J. Mech. Phys. Solids 69, 14–32 (2014).

J. Lloyd, J. Clayton, R. Becker, and D. McDowell: Simulation of shock wave propagation in single crystal and polycrystalline aluminum. Int. J. Plast. 60, 118–144 (2014).

R. Austin: Elastic precursor wave decay in shock-compressed aluminum over a wide range of temperature. J. Appl. Phys. 123, 035103 (2018).

T. Zhu, J. Li, A. Samanta, A. Leach, and L. Gall: Temperature and strain-rate dependence of surface dislocation nucleation. Phys. Rev. Lett. 100, 025502 (2008).

H. Van Swygenhoven, P. Derlet, and A. Froseth: Nucleation and propagation of dislocations in nanocrystalline fcc metals. Acta Mater. 54, 1975–1983 (2006).

T. Zhu, J. Li, A. Samanta, H. Kim, and S. Suresh: Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proc. Natl. Acad. Sci. U. S. A. 104, 3031–3036 (2007).

T. Zhu and J. Li: Ultra-strength materials. Prog. Mater. Sci. 55, 710–757 (2010).

T. Lee, I. Robertson, and H. Birnbaum: Prediction of slip transfer mechanisms across grain boundaries. Scr. Metall. 23, 799–803 (1989).

A. Hunter, B. Leu, and I. Beyerlein: A review of slip transfer: Applications of mesoscale techniques. J. Mater. Sci. 53, 5584–5603 (2018).

J. Weertman: High velocity dislocations. In Response of Metals to High Velocity Deformation. Metallurgical Society Conferences, Vol. 9, P. Shewmon and V. Zackay, eds. (Interscience, New York, 1961); pp. 205–249.

R. Clifton and X. Markenscoff: Elastic precursor decay and radiation from nonuniformly moving dislocations. J. Mech. Phys. Solids 29, 227–251 (1981).

B. Gurrutxaga-Lerma, D. Balint, D. Dini, and A. Sutton: The mechanisms governing the activation of dislocation sources in aluminum at different strain rates. J. Mech. Phys. Solids 84, 273–292 (2015).

W. Greenman, T. Vreeland, Jr., and D. Wood: Dislocation mobility in copper. J. Appl. Phys. 38, 3595–3603 (1967).

J. Chen, M. Tschopp, and A. Dongare: Shock wave propagation and spall failure of nanocrystalline Cu/Ta alloys: Effect of Ta in solid-solution. J. Appl. Phys. 122, 225901 (2017).

S. Joshi and K. Ramesh: Stability map for nanocrystalline and amorphous materials. Phys. Rev. Lett. 101, 025501 (2008).

Y. Guo, Y. Li, Z. Pan, F. Zhou, and Q. Wei: A numerical study of microstructure effect on adiabatic shear instability: Application to nanostructured/ultrafine grained materials. Mech. Mater. 42, 1020–1029 (2010).

J. Eshelby: Uniformly moving dislocations. Proc. Phys. Soc. 62, 307 (1949).

E. Van der Giessen and A. Needleman: Discrete dislocation plasticity: A simple planar model. Modell. Simul. Mater. Sci. Eng. 3, 689 (1995).

B. Gurrutxaga-Lerma, D. Balint, D. Dini, D. Eakins, and A. Sutton: Dynamic discrete dislocation plasticity. In Advances in Applied Mechanics, S. Bordas, ed. Vol. 47 (Elsevier, London, U.K., 2014); ch. 2, pp. 93–224.

X. Markenscoff and R. Clifton: The nonuniformly moving edge dislocation. J. Mech. Phys. Solids 29, 253–262 (1981).

B. Gurrutxaga-Lerma, D. Balint, D. Dini, D. Eakins, and A. Sutton: A dynamic discrete dislocation plasticity method for the simulation of plastic relaxation under shock loading. Proc. R. Soc. A 469, 20130141 (2013).

K. Darling, C. Kale, S. Turnage, B. Hornbuckle, T. Luckenbaugh, S. Grendahl, and K. Solanki: Nanocrystalline material with anomalous modulus of resilience and springback effect. Scr. Mater. 141, 36–40 (2017).

Acknowledgments

I wish to thank Drs. Kris Darling and Heather Murdoch for fruitful discussions concerning the behavior of nanocrystalline metals, and Dr. Beñat Gurrutxaga-Lerma for discussing elastodynamic dislocation solutions and their implementation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lloyd, J.T. High-rate dislocation motion in stable nanocrystalline metals. Journal of Materials Research 34, 2252–2262 (2019). https://doi.org/10.1557/jmr.2019.59

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.59