Abstract

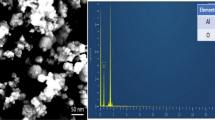

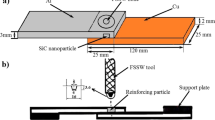

Effects of varying volume fractions of SiC nanoparticle (SiCNP) reinforcement on microstructure and mechanical properties of dissimilar AA2024-T351 and AA7075-T651 joints by friction stir welding (FSW) have been investigated experimentally. A rectangular section edge groove was prepared at the adjoining surfaces of the two plates with the butt configuration before FSW. Initially, four fractional volumes with 0, 5, 8, and 13% of SiCNP are reinforced into the grooves of width, 0, 0.2, 0.3, and 0.5 mm and the FSW was performed with the first and second pass to obtain metal matrix nanocomposite (MMNC) at the weld nugget zone (WNZ). The characterization of microstructure specimens was investigated using optical microscopy (OM), scanning electron microscopy (SEM) and X-ray diffraction technique (XRD). The FSW joint specimen produced with 5 vol% fraction of SiCNP for second pass processing observes a defect-free, homogeneous distribution of SiCNP with a mean grain size of about 2–3 µm at the WNZ and weld joints higher in tensile strength, 411 MPa, yield strength, 252 MPa, and percentage elongation, 14.3. The result shows that varying volume fractions (5, 8, 13%) of the SiCNP after the FSW second pass led to significant grain refinement at the WNZ and higher mechanical properties compared with FSW specimens prepared without SiCNP. Higher hardness of 150 Hv was observed in the WNZ for specimen produced with 13 vol% fraction SiCNP.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Templesmith, and C.J. Dawes: Friction stir welding. GB Patent Application No. 9125978 and U.S. Patent No. 5460317, October 24, 1995.

R.S. Mishra and Z.Y. Ma: Friction stir welding and processing. Mater. Sci. Eng., R 50, 1 (2005).

Y. Yang, J. Lan, and X. Li: Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy. Mater. Sci. Eng., A 380, 378 (2004).

W.L. GU: Bulk Al/SiC nanocomposite prepared by ball milling and hot pressing method. Trans. Nonferrous Met. Soc. China 16, 398 (2006).

C. Carreño-Gallardo, I. Estrada-Guel, C. López-Meléndez, and R. Martínez-Sánchez: Dispersion of silicon carbide nanoparticles in a AA2024 aluminum alloy by a high-energy ball mill. J. Alloys Compd. 586, 68 (2014).

S.O. Min: Effects of volume fraction of SiC particles on mechanical properties of SiC/Al composites. Trans. Nonferrous Met. Soc. China 19, 1400 (2009).

Z.Y. Ma, Y.L. Li, Y. Liang, F. Zheng, J. Bi, and S.C. Tjong: Nanometric Si3N4 particulate-reinforced aluminum composite. Mater. Sci. Eng., A 219, 229 (1996).

M. Rahimian, N. Parvin, and N. Ehsani: Investigation of particle size and amount of alumina on microstructure and mechanical properties of Al matrix composite made by powder metallurgy. Mater. Sci. Eng., A 527, 1031 (2010).

M. Rahimian, N. Parvin, and N. Ehsani: Size dependent strengthening in particle reinforced aluminium. Acta Mater. 50, 39 (2002).

A. Kawabe, A. Oshida, T. Kobayashi, and H. Toda: Fabrication process of metal matrix composite with nano-size SiC particle produced by vortex method. J. Jpn. Inst. Light Met. 49, 149 (1999).

C. Don-Hyun, K. Yong-Il, K. Dae-Up, and J.U. Seung-Boo: Effect of SiC particles on microstructure and mechanical property of friction stir processed AA6061-T4. Trans. Nonferrous Met. Soc. China 22, 614 (2012).

H.R. Akramifard, M. Shamanian, M. Sabbaghian, and M. Esmailzadeh: Microstructure and mechanical properties of Cu/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 54, 838 (2014).

W. Wang, Q.Y. Shi, P. Liu, H.K. Li, and T. Li: A novel way to produce bulk SiCp reinforced aluminum metal matrix composites by friction stir processing. J. Mater. Process. Technol. 209, 2099 (2009).

A. Dolatkhah, P. Golbabaei, M.B. Givi, and F. Molaiekiya: Investigating effects of process parameters on microstructural and mechanical properties of Al5052/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 37, 458 (2012).

M. Azizieh, A.H. Kokabi, and P. Abachi: Effect of rotational speed and probe profile on microstructure and hardness of AZ31/Al2O3 nanocomposites fabricated by friction stir processing. Mater. Des. 32, 2034 (2011).

R. Sathiskumar, N. Murugan, I. Dinaharan, and S.J. Vijay: Characterization of boron carbide particulate reinforced in situ copper surface composites synthesized using friction stir processing. Mater. Charact. 84, 16 (2013).

M. Abbasi, A. Abdollahzadeh, B. Bagheri, and H. Omidvar: The effect of SiC particle addition during FSW on microstructure and mechanical properties of AZ31 magnesium alloy. J. Mater. Eng. Perform. 24, 5037 (2015).

M. Bahrami, K. Dehghani, and M.K. Givi: A novel approach to develop aluminum matrix nano-composite employing friction stir welding technique. Mater. Des. 53, 217 (2014).

M. Tabasi, M. Farahani, M.B. Givi, M. Farzami, and A. Moharami: Dissimilar friction stir welding of 7075 aluminum alloy to AZ31 magnesium alloy using SiC nanoparticles. Int. J. Adv. Des. Manuf. Technol. 86, 705 (2016).

H. Liu, Y. Hu, Y. Zhao, and H. Fujii: Microstructure and mechanical properties of friction stir welded AC4A + 30 vol% SiCp composite. Mater. Des. 65, 395 (2015).

A.H. Byung-Wook, C.H. Don-Hyun, K.I. Yong-Hwan, and J.U. Seung-Boo: Fabrication of SiCp/AA5083 composite via friction stir welding. Trans. Nonferrous Met. Soc. China 22, 634 (2012).

D.I. Pantelis, P.N. Karakizis, N.M. Daniolos, C.A. Charitidis, E.P. Koumoulos, and D.A. Dragatogiannis: Microstructural study and mechanical properties of dissimilar friction stir welded AA5083-H111 and AA6082-T6 reinforced with SiC nanoparticles. Mater. Manuf. Processes 31, 264 (2016).

Y.F. Sun and H. Fujii: The effect of SiC particles on the microstructure and mechanical properties of friction stir welded pure copper joints. Mater. Sci. Eng., A 528, 5470 (2011).

A. Hamdollahzadeh, M. Bahrami, M.F. Nikoo, A. Yusefi, M.B. Givi, and N. Parvin: Microstructure evolutions and mechanical properties of nano-SiC-fortified AA7075 friction stir weldment: The role of second pass processing. J. Manuf. Process. 20, 367 (2015).

M.M. El-Rayes and E.A. El-Danaf: The influence of multi-pass friction stir processing on the microstructural and mechanical properties of Aluminum Alloy 6082. J. Mater. Process. Technol. 212, 1157 (2012).

M. Bahrami, M.K. Givi, K. Dehghani, and N. Parvin: On the role of pin geometry in microstructure and mechanical properties of AA7075/SiC nano-composite fabricated by friction stir welding technique. Mater. Des. 53, 519 (2014).

M. Salehi, M. Saadatmand, and J.A. Mohandesi: Optimization of process parameters for producing AA6061/SiC nanocomposites by friction stir processing. Trans. Nonferrous Met. Soc. China 22, 1055 (2012).

K.R. Seighalani, M.B. Givi, A.M. Nasiri, and P. Bahemmat: Investigations on the effects of the tool material, geometry and tilt angle on friction stir welding of pure titanium. J. Mater. Eng. Perform. 19, 955 (2010).

B.A. Kumar and N. Murugan: Optimization of friction stir welding process parameters to maximize tensile strength of stir cast AA6061-T6/AlNp composite. Mater. Des. 57, 383 (2014).

R. Sathiskumar, I. Dinaharan, N. Murugan, and S.J. Vijay: Influence of tool rotational speed on microstructure and sliding wear behavior of Cu/B4C surface composite synthesized by friction stir processing. Trans. Nonferrous Met. Soc. China 25, 95 (2015).

S. Tutunchilar, M. Haghpanahi, M.B. Givi, P. Asadi, and P. Bahemmat: Simulation of material flow in friction stir processing of a cast Al–Si alloy. Mater. Des. 40, 415 (2012).

J. Guo, B.Y. Lee, Z. Du, G. Bi, M.J. Tan, and J. Wei: Effect of nano-particle addition on grain structure evolution of friction stir-processed Al6061 during postweld annealing. JOM 68, 2268 (2016).

Z. Wang, M. Song, C. Sun, and Y. He: Effects of particle size and distribution on the mechanical properties of SiC reinforced Al–Cu alloy composites. Mater. Sci. Eng., A 528, 1131 (2011).

A. Slipenyuk, V. Kuprin, Y. Milman, V. Goncharuk, and J. Eckert: Properties of P/M processed particle reinforced metal matrix composites specified by reinforcement concentration and matrix-to-reinforcement particle size ratio. Acta Mater. 54, 157 (2006).

R. Palanivel, P.K. Mathews, N. Murugan, and I. Dinaharan: Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Mater. Des. 40, 7 (2012).

G.E. Dieter and D. Bacon: Mechanical Metallurgy (McGraw-Hill, London, 1988).

M. Rahimian, N. Ehsani, N. Parvin, and H.R. Baharvandi: The effect of sintering temperature and the amount of reinforcement on the properties of Al–Al2O3 composite. Mater. Des. 30, 3333 (2009).

M. Bodaghi and K. Dehghani: Friction stir welding of AA5052: The effects of SiC nano-particles addition. Int. J. Adv. Des. Manuf. Technol. 88, 2651 (2017).

S.A. Khodir and T. Shibayanagi: Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng., B 148, 82 (2008).

M. Barmouz, P. Asadi, M.B. Givi, and M. Taherishargh: Investigation of mechanical properties of Cu/SiC composite fabricated by FSP: Effect of SiC particles size and volume fraction. Mater. Sci. Eng., A 528, 1740 (2011).

Y. Morisada, H. Fujii, T. Nagaoka, and M. Fukusumi: Effect of friction stir processing with SiC particles on microstructure and hardness of AZ31. Mater. Sci. Eng., A 433, 50 (2006).

S. Scudino, G. Liu, K.G. Prashanth, B. Bartusch, K.B. Surreddi, B.S. Murty, and J. Eckert: Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 57, 2029 (2009).

M.F. Ashby: The theory of the critical shear stress and work hardening of dispersion-hardened crystals. In Proceeding of Second Bolton Landing Conference on Oxide Dispersion Strengthening (Gordon and Breach, Science Publishers, Inc., New York, 1968); p. 143.

N. Hansen: The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall. 25, 863 (1977).

E.O. Hall: The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. B 64, 747 (1951).

H.S. Kim: On the rule of mixtures for the hardness of particle reinforced composites. Mater. Sci. Eng., A 289, 30 (2000).

C.S. Kim, I. Sohn, M. Nezafati, J.B. Ferguson, B.F. Schultz, Z. Bajestani-Gohari, P.K. Rohatgi, and K. Cho: Prediction models for the yield strength of particle-reinforced unimodal pure magnesium (Mg) metal matrix nanocomposites (MMNCs). J. Mater. Sci. 48, 4191 (2013).

A.M. Redsten, E.M. Klier, A.M. Brown, and D.C. Dunand: Mechanical properties and microstructure of cast oxide-dispersion-strengthened aluminum. Mater. Sci. Eng., A 201, 88 (1995).

Z. Wang, R.T. Qu, S. Scudino, B.A. Sun, K.G. Prashanth, D.V. Louzguine-Luzgin, M.W. Chen, Z.F. Zhang, and J. Eckert: Hybrid nanostructured aluminum alloy with super-high strength. NPG Asia Mater. 7, e229 (2015).

D. Markó, K.G. Prashanth, S. Scudino, Z. Wang, N. Ellendt, V. Uhlenwinkel, and J. Eckert: Al-based metal matrix composites reinforced with Fe49.9Co35.1Nb7.7B4.5Si2.8 glassy powder: Mechanical behavior under tensile loading. J. Alloys Compd. 615, S382 (2014).

R. Vogt, Z. Zhang, Y. Li, M. Bonds, N.D. Browning, E.J. Lavernia, and J.M. Schoenung: The absence of thermal expansion mismatch strengthening in nanostructured metal–matrix composites. Scr. Mater. 61, 1052 (2009).

A. Kumar, D. Yadav, C.S. Perugu, and S.V. Kailas: Influence of particulate reinforcement on microstructure evolution and tensile properties of in-situ polymer derived MMC by friction stir processing. Mater. Des. 113, 99 (2017).

Acknowledgments

The authors would like to thank Prof. Sathish V. Kailas, Department of Mechanical Engineering, Indian Institute of Science (IISc.), Bangalore, for his support and providing the FSW machine and facilities available at Surface Interaction and Manufacturing (SIAM) Lab for experimentations.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Anil Kumar, K.S., Murigendrappa, S.M. & Kumar, H. Experimental investigation on effects of varying volume fractions of SiC nanoparticle reinforcement on microstructure and mechanical properties in friction-stir-welded dissimilar joints of AA2024-T351 and AA7075-T651. Journal of Materials Research 34, 1229–1247 (2019). https://doi.org/10.1557/jmr.2018.445

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.445