Abstract

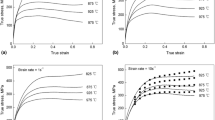

Hot compression tests on pure Ni and Ni–30Cu at 950–1150 °C and strain rates of 0.001–1 s−1 were performed to identify the physical interpretation of the apparent activation energy (Qd). For pure Ni, Qd was constant and identical to that of the self-diffusion. However, for Ni–30Cu, it decreased steadily with strain. The value of Qd was separated into thermal and mechanical parts. The thermal part was necessary to propel diffusion. For pure Ni, the mechanical part was zero at low and medium strain rates of 0.001–0.1 s−1 and the self-diffusion was the controlling mechanism. However, at 1 s−1, both the thermal and mechanical parts were needed to provide Qd. For Ni–30Cu, Qd was greater than that for the interdiffusion of Ni and Cu. The value of mechanical part decreased with increasing temperature and strain rate. Although the thermal parts for pure Ni and Ni–30Cu were nearly identical, the mechanical part for the latter was considerably higher. The difference was attributed to the strengthening effect of Cu atoms and the sluggish dynamic softening with respect to pure Ni.

Similar content being viewed by others

References

Y.C. Lin, M-S. Chen, and J. Zhong: Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 42, 470 (2008).

G.R. Ebrahimi, A. Momeni, S.M. Abbasi, and H. Monajatizadeh: Constitutive analysis and processing map for hot working of a Ni–Cu alloy. Met. Mater. Int. 19, 11 (2013).

Y. Zhou, Y. Liu, X. Zhou, C. Liu, L. Yu, C. Li, and B. Ning: Processing maps and microstructural evolution of the type 347H austenitic heat-resistant stainless steel. J. Mater. Res. 30, 2090 (2015).

A. Momeni, S.M. Abbasi, M. Morakabati, H. Badri, and X. Wang: Dynamic recrystallization behavior and constitutive analysis of Incoloy 901 under hot working condition. Mater. Sci. Eng., A 615, 51 (2014).

C. Zhang, L. Zhang, M. Li, W. Shen, and S. Gu: Effects of microstructure and γ′ distribution on the hot deformation behavior for a powder metallurgy superalloy FGH96. J. Mater. Res. 29, 2799 (2014).

S.V. Mehtonen, L.P. Karjalainen, and D.A. Porter: Hot deformation behavior and microstructure evolution of a stabilized high-Cr ferritic stainless steel. Mater. Sci. Eng., A 571, 1 (2013).

B. Verlinden, J. Driver, I. Samajdar, and R.D. Doherty: Thermomechanical Processing of Metallic Materials, R.W. Cahn ed. (Elsevier-Pergamon: London, 2007).

A. Momeni, S. Kazemi, G.R. Ebrahimi, and A. Maldar: Dynamic recrystallization and precipitation in high manganese austenitic stainless steel during hot compression. Int. J. Miner., Metall. Mater. 21, 36 (2014).

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, and M. He: Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater. Des. 57, 568 (2014).

S. Mitsche, C. Sommitch, D. Huber, M. Stockinder, and P. Poelt: Assessment of dynamic softening mechanisms in Allvac® 718Plus™ by EBSD analysis. Mater. Sci. Eng., A 528, 3754 (2011).

H. Zhang, K. Zhang, S. Jiang, and Z. Lu: The dynamic recrystallization evolution and kinetics of Ni–18.3Cr–6.4Co–5.9W–4Mo–2.19Al–1.16Ti superalloy during hot deformation. J. Mater. Res. 30, 1029 (2015).

D. Hull and D.J. Bacon: Introduction to Dislocations, 4th ed. (Butterworth-Heinemann, London, 2001).

V.V. Shastry, B. Maji, M. Krishnan, and U. Ramamurty: High-temperature deformation processing maps for a NiTiCu shape memory alloy. J. Mater. Res. 26, 2484 (2011).

S.M. Abbasi, A. Momeni, A. Akhondzadeh, and S.M. Ghazi Mirsaed: Microstructure and mechanical behavior of hot compressed Ti–6V–6Mo–6Fe–3Al. Mater. Sci. Eng., A 639, 21 (2015).

Y.C. Lin, M-S. Chen, and J. Zhong: Effect of temperature and strain rate on the compressive deformation behavior of 42CrMo steel. J. Mater. Process. Technol. 205, 308 (2008).

N. Liu, Z. Li, L. Li, B. Liu, and G-Y. Xu: Processing map and hot deformation mechanism of novel nickel-free white copper alloy. Trans. Nonferrous Met. Soc. China 24, 3492 (2014).

Y.V.R.K. Prasad and S. Sasidhara, eds.: Hot Working Guide, A Compendium of Processing Maps (ASM, Materials Park: Ohio, 1997).

G. Gandhi: On fracture initiation mechanisms and dynamic recrystallization during hot deformation of pure nickel. Metall. Trans. A 13, 1233 (1982).

Q.G. Zheng: Characterization for dynamic recrystallization kinetics based on stress-strain curves. In Recent Developments in the Study of Recrystallization, P. Wilson, ed. (INTECH: Rijeka, Croatia, 2013); ch. 2. doi: https://doi.org/10.5772/54285.

S.M. Abbasi, M. Morakabati, A.H. Sheikhali, and A. Momeni: Hot deformation behavior of beta titanium Ti-13V-11Cr-3Al alloy. Metall. Mater. Trans. A 45, 5201 (2014).

M. Shakiba, N. Parson, and X-G. Chen: Hot deformation behavior and rate-controlling mechanism in dilute Al–Fe–Si alloys with minor additions of Mn and Cu. Mater. Sci. Eng., A 636, 572 (2015).

G. Neumann and C. Tuijn: Self-dissusion and Impurity Diffusion in Pure Metals: Handbook of Experimental Data (Elsevier-Pergamon, London, 2009).

K. Monma, H. Suto, and H. Oikawa: Diffusion of Ni and Cu in nickel-copper alloys. Nippon Kinzoku Gakkaishi 28, 192 (1964).

U.F. Kocks, A.S. Argon, and M.F. Ashby: Thermodynamics and kinetics of slip. Prog. Mater. Sci. 19, 1 (1975).

S.M. Abbasi and A. Momeni: Hot working behavior of Fe–29Ni–17Co analyzed by mechanical testing and processing map. Mater. Sci. Eng., A 552, 330 (2012).

E. Shapiro and G.E. Dieter: Fracture and ductility in hot torsion of nickel. Metall. Trans. 2, 1385 (1971).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Momeni, A. The physical interpretation of the activation energy for hot deformation of Ni and Ni–30Cu alloys. Journal of Materials Research 31, 1077–1084 (2016). https://doi.org/10.1557/jmr.2016.81

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.81