Abstract

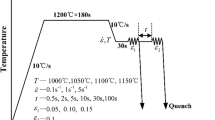

The metadynamic recrystallization (MDRX) behaviors in deformed Nimonic 80A superalloy were investigated by isothermal interrupted hot compression tests on a Gleeble-1500 thermo-mechanical simulator. Compression tests were performed using double hit schedules in the deformation temperature range of 1050–1150 °C, the interpass time range of 0.5–10 s, the strain rate range of 0.01–4 s−1, and the prestrain range of 0.30–0.50. To characterize the MDRX behaviors of the alloy, the effects of deformation temperature, strain rate, and prestrain on the metadynamic softening and recrystallized grain size were analyzed. The results reveal that the effects of deformation temperature and strain rate on the metadynamic softening fraction and recrystallized grain size are significant. However, the effects of prestrain on the metadynamic softening fraction and recrystallized grain size are not very marked and can be neglected. Then, by regression analysis of the experimental data, the MDRX kinetic model and recrystallized grain size model were proposed. The predicted results show good agreement with the experimental ones, which indicates that the proposed models can give an accurate prediction of the softening behaviors and microstructural evolution for Nimonic 80A.

Similar content being viewed by others

References

Y.L. Xu, C.X. Yang, Q.X. Ran, P.F. Hu, X.S. Xiao, X.L. Cao, and G.Q. Jia: Microstructure evolution and stress-rupture properties of Nimonic 80A after various heat treatments. Mater. Des. 47, 218–226 (2013).

Y.L. Xu, Q.M. Jin, X.S. Xiao, X.L. Cao, G.Q. Jia, Y.M. Zhu, and H.J. Yin: Strengthening mechanisms of carbon in modified nickel-based superalloy Nimonic 80A. Mater. Sci. Eng., A 528 (13–14), 4600–4607 (2011).

H.S. Jeong, J.R. Cho, and H.C. Park: Microstructure prediction of Nimonic 80A for large exhaust valve during hot closed die forging. J. Mater. Process. Technol. 162–163, 504–511 (2005).

B. Wilthan, K. Preis, R. Tanzer, W. Schützenhöfer, and G. Pottlacher: Thermophysical properties of the Ni-based alloy Nimonic 80A up to 2400 K, II. J. Alloys Compd. 452 (1), 102–104 (2008).

B. Wilthan, R. Tanzer, W. Schützenhöfer, and G. Pottlacher: Thermophysical properties of the Ni-based alloy Nimonic 80A up to 2400K, III. Thermochim. Acta 465 (1–2), 83–87 (2007).

D. Bombac, M. Brojan, M. Tercelj, and R. Turk: Response to hot deformation conditions and microstructure development of Nimonic 80A superalloy. Mater. Manuf. Processes 24 (6), 644–648 (2009).

B.H. Tian, C. Lind, E. Schafler, and O. Paris: Evolution of microstructures during dynamic recrystallization and dynamic recovery in hot deformed Nimonic 80a. Mater. Sci. Eng., A 367 (1–2), 198–204 (2004).

M. Kazeminezhad: On the modeling of the static recrystallization considering the initial grain size effects. Mater. Sci. Eng., A 486 (1–2), 202–207 (2008).

K.P. Rao, Y.K.D.V. Prasad, and E.B. Hawbolt: Study of fractional softening in multi-stage hot deformation. J. Mater. Process. Technol. 77 (1), 166–174 (1998).

F. Chen and Z.S. Cui: Mesoscale simulation of microstructure evolution during multi-stage hot forging processes. Modell. Simul. Mater. Sci. Eng. 20 (4), 045008(pp. 16) (2012).

S. Serajzadeh: A study on kinetics of static and metadynamic recrystallization during hot rolling. Mater. Sci. Eng., A 448 (1–2), 146–153 (2007).

S.D. Gu, L.W. Zhang, C.X. Yue, J.H. Ruan, J.L. Zhang, and H.J. Gao: Multi-field coupled numerical simulation of microstructure evolution during the hot rolling process of GCr15 steel rod. Comput. Mater. Sci. 50 (7), 1951–1957 (2011).

S. Solhjoo and R. Ebrahimi: Prediction of no-recrystallization temperature by simulation of multi-pass flow stress curves from single-pass curves. J. Mater. Sci. 45 (21), 5960–5966 (2010).

C. Roucoules, S. Yue, and J.J. Jonas: Effect of alloying elements on metadynamic recrystallization in HSLA steels. Metall. Mater. Trans. A 26 (1), 181–190 (1995).

S.H. Cho and Y.C. Yoo: Determination of the metadynamic recrystallization parameter for AISI 304 stainless steel. J. Mater. Sci. Lett. 18 (12), 987–989 (1999).

P.D. Hodgson: Microstructure modelling for property prediction and control. J. Mater. Process. Technol. 60 (1), 27–33 (1996).

R.A.P. Djaic and J.J. Jonas: Recrystallization of high carbon steel between intervals of high temperature deformation. Met. Trans. 4 (2), 621–624 (1973).

K.H. Jung, H.W. Lee, and Y.T. Im: Numerical prediction of austenite grain size in a bar rolling process using an evolution model based on a hot compression test. Mater. Sci. Eng., A 519 (1–2), 94–104 (2009).

A.M. Elwazri, P. Wanjara, and S. Yue: Dynamic recrystallization of austenite in microalloyed high carbon steels. Mater. Sci. Eng., A 339, 209–215 (2003).

B. Ma, Y. Peng, Y.F. Liu, and B. Jia: Modeling of metadynamic recrystallization kinetics after hot deformation of low-alloy steel Q345B. J. Cent. South Univ. Technol. 17, 911–917 (2010).

Y.C. Lin, M.S. Chen, and J. Zhong: Study of metadynamic recrystallization behaviors in a low alloy steel. J. Mater. Process. Technol. 209 (5), 2477–2482 (2009).

Y.C. Lin and M.S. Chen: Study of microstructural evolution during metadynamic recrystallization in a low-alloy steel. Mater. Sci. Eng., A 501 (1–2), 229–234 (2009).

Y.C. Lin, L.T. Li, and Y.C. Xia: A new method to predict the metadynamic recrystallization behavior in 2124 aluminum alloy. Comput. Mater. Sci. 50 (7), 2038–2043 (2011).

J. Liu, Y.G. Liu, H. Lin, and M.Q. Li: The metadynamic recrystallization in the two-stage isothermal compression of 300M steel. Mater. Sci. Eng., A 565, 126–131 (2013).

L. Cheng, H. Chang, B. Tang, H.C. Kou, and J.S. Li: Characteristics of metadynamic recrystallization of a high Nb containing TiAl alloy. Mater. Lett. 92, 430–432 (2013).

C.X. Yue, L.W. Zhang, S.L. Liao, and H.J. Gao: Mathematical models for predicting the austenite grain size in hot working of GCr15 steel. Comput. Mater. Sci. 45 (2), 462–466 (2009).

A. Yanagida and J. Yanagimoto: Formularization of softening fractions and related kinetics for static recrystallization using inverse analysis of double compression test. Mater. Sci. Eng., A 487 (1–2), 510–517 (2008).

A. Dehghan-Manshadi, M.R. Barnett, and P.D. Hodgson: Hot deformation and recrystallization of austenitic stainless steel: Part II. Post-deformation recrystallization. Metall. Mater. Trans. A 39 (6), 1371–1381 (2008).

S. Choi and Y. Lee: A new approach to predicting partial recrystallization in the multi-pass hot rolling process. Met. Mater. Int. 8 (1), 15–23 (2002).

F. Chen, Z.S. Cui, D.S. Sui, and B. Fu: Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation. Part III: Metadynamic recrystallization. Mater. Sci. Eng., A 540, 46–54 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, S., Zhang, C., Zhang, L. et al. Characteristics of metadynamic recrystallization of Nimonic 80A superalloy. Journal of Materials Research 30, 538–546 (2015). https://doi.org/10.1557/jmr.2015.7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.7