Abstract

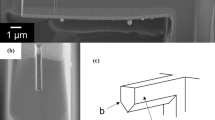

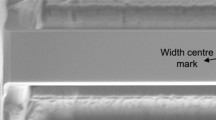

Copper microcantilevers were produced by focused ion beam milling and tested in situ using a scanning electron microscope. To provide different interfaces for piling up dislocations, cantilevers were fabricated to be single crystalline, bicrystalline, or single crystalline with a slit in the region of the neutral axis. The aim of the experiment was to study the influence of dislocation pile-ups on (i) strength and (ii) Bauschinger effects in micrometer-sized, focused ion beam milled bending cantilevers. The samples were loaded monotonically for several times under displacement control. Even though the cantilevers exhibited the same nominal strain gradient the strength varied by 34% within the three cantilever geometries. The Bauschinger effect can be promoted and prohibited by the insertion of different interfaces.

Similar content being viewed by others

References

C. Motz, T. Schöberl, and R. Pippan: Mechanical properties of micro-sized copper bending beams machined by the focused ion beam technique. Acta Mater. 53 (15), 4269 (2005).

J. Gong and A.J. Wilkinson: A microcantilever investigation of size effect, solid-solution strengthening and second-phase strengthening for prism slip in alpha-Ti. Acta Mater. 59 (15), 5970 (2011).

E. Demir, D. Raabe, and F. Roters: The mechanical size effect as a mean-field breakdown phenomenon: Example of microscale single crystal beam bending. Acta Mater. 58 (5), 1876 (2010).

D. Kiener, C. Motz, W. Grosinger, D. Weygand, and R. Pippan: Cyclic response of copper single crystal micro-beams. Scr. Mater. 63 (5), 500 (2010).

C. Kirchlechner, W. Grosinger, M.W. Kapp, P.J. Imrich, J.S. Micha, O. Ulrich, J. Keckes, G. Dehm, and C. Motz: Investigation of reversible plasticity in a micron-sized, single crystalline copper bending beam by x-ray μ Laue diffraction. Philos. Mag. 92 (25–27), 3231 (2012).

O. Kraft, P.A. Gruber, R. Mönig, and D. Weygand: Plasticity in confined dimensions. Annu. Rev. Mater. Res. 40, 293 (2010).

J.R. Greer and J.T.M. De Hosson: Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56 (6), 654 (2011).

N.A. Fleck, G.M. Muller, M.F. Ashby, and J.W. Hutchinson: Strain gradient plasticity: Theory and experiment. Acta Metall. Mater. 42 (2), 475 (1994).

J.S. Stölken and A.G. Evans: A microbend test method for measuring the plasticity length scale. Acta Mater. 46 (14), 5109 (1998).

A.J. Bushby and D.J. Dunstan: Size effects in yield and plasticity under uniaxial and non-uniform loading: Experiment and theory. Philos. Mag. 91 (7–9), 1037 (2010).

M.D. Uchic, D.M. Dimiduk, J.N. Florando, and W.D. Nix: Sample dimensions influence strength and crystal plasticity. Science 305 (5686), 986 (2004).

C.A. Volkert and E.T. Lilleodden: Size effects in the deformation of sub-micron Au columns. Philos. Mag. 86 (33–35), 5567 (2006).

D. Kiener, W. Grosinger, G. Dehm, and R. Pippan: A further step towards an understanding of size-dependent crystal plasticity: In situ tension experiments of miniaturized single-crystal copper samples. Acta Mater. 56 (3), 580 (2008).

J.Y. Kim, D.C. Jong, and J.R. Greer: Tensile and compressive behavior of tungsten, molybdenum, tantalum and niobium at the nanoscale. Acta Mater. 58 (7), 2355 (2010).

C. Motz, D. Weygand, J. Senger, and P. Gumbsch: Initial dislocation structures in 3-D discrete dislocation dynamics and their influence on microscale plasticity. Acta Mater. 56 (6), 1942 (2008).

S. Suresh: Fatigue of Materials (Cambridge University Press, Cambridge, 1998).

O.B. Pedersen, L.M. Brown, and W.M. Stobbs: The Bauschinger effect in copper. Acta Metall. 29 (11), 1843 (1981).

J. Rajagopalan, C. Rentenberger, H. Peter Karnthaler, G. Dehm, and M.T.A. Saif: In situ TEM study of microplasticity and Bauschinger effect in nanocrystalline metals. Acta Mater. 58 (14), 4772 (2010).

Y. Xiang and J.J. Vlassak: Bauschinger and size effects in thin-film plasticity. Acta Mater. 54 (20), 5449 (2006).

J. Gong and A.J. Wilkinson: Anisotropy in the plastic flow properties of single-crystal α titanium determined from micro-cantilever beams. Acta Mater. 57 (19), 5693 (2009).

D. Raabe, D. Ma, and F. Roters: Smaller is stronger: The effect of strain hardening. Acta Mater. 55 (20), 4567 (2007).

G. Moser, H. Felber, B. Rashkova, P.J. Imrich, C. Kirchlechner, W. Grosinger, C. Motz, G. Dehm, and D. Kiener: Sample preparation by metallography and focused ion beam for nanomechanical testing. Prakt. Metallogr. 49 (6), 343 (2012).

F.F. Csikor, C. Motz, D. Weygand, M. Zaiser, and S. Zapperi: Dislocation avalanches, strain bursts, and the problem of plastic forming at the micrometer scale. Science 318 (5848), 251 (2007).

ACKNOWLEDGMENTS

The authors thank Prof. Z. F. Zhang from the Shenyang National Laboratory (China) for providing one macroscopic bicrystal, Prof. C. Motz from Universität des Saarlandes, Saarbrücken (Germany) for valuable discussion, and Dr. S. Brinckmann from the MPIE for additional FEM analysis justifying the assumed stress distribution in the cantilever. Financial support by the FWF Austrian Science Fund through project number P24429-N20 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kapp, M.W., Kirchlechner, C., Pippan, R. et al. Importance of dislocation pile-ups on the mechanical properties and the Bauschinger effect in microcantilevers. Journal of Materials Research 30, 791–797 (2015). https://doi.org/10.1557/jmr.2015.49

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.49