Abstract

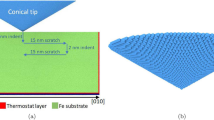

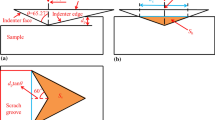

For a number of polymers with a variety of chemical structures and different properties, we have performed scratch-resistance tests and investigated the profiles of the grooves formed using a profilometer. Three main kinds of material response are seen: plowing; cutting; and densification. The cross-sectional areas of the grooves include the groove and side top-ridge areas. The latter are smaller than the former, an indication of densification at the bottom and the sides of the groove; the effect can be connected to molecular dynamics simulations of scratch testing. The sum of the groove and top-ridge areas is the highest for Teflon, thus providing another measure of its poor scratch resistance. The Vickers hardness of the polymers was also determined. An approximate relationship exists between the hardness and the groove area. An unequivocal relationship between the hardness and the total cross-sectional area of the material displaced by the indenter is found. The resulting curve can be represented by an exponential decay function.

Similar content being viewed by others

References

E. Rabinowicz Friction and Wear of Materials 2 ed. Wiley New York 1995

M.D. Bermúdez, W. Brostow, F.J. Carrión-Vilches, J.J. Cervantes D. Pietkiewicz: Friction and multiple scratch behavior of polymer + monomer liquid crystal systems. Polymer 46, 347 2005

B. Bhushan: Introduction to Tribology Wiley New York 2002 Chap. 7

N.K. Myshkin, M.I. Petrokovets A.V. Kovalev: Tribology of polymers: Adhesion, friction, wear, and mass-transfer. Tribol. Int. 38, 910 2005

W. Brostow, J-L. Deborde, M. Jaklewicz P. Olszynski: Tribology with emphasis on polymers: Friction, scratch resistance and wear. J. Mater. Ed. 25, 119 2003

W. Brostow, M. Keselman, I. Mironi-Harpaz, M. Narkis R. Peirce: Effects of carbon black on tribology of blends of poly(vinylidene fluoride) with irradiated and non-irradiated ultrahigh-molecular-weight polyethylene. Polymer 46, 5058 2005

B.J. Briscoe, E. Pelillo, S.K. Sinha P.D. Evans: Scratching maps for polymers. Wear 200, 137 1996

K. Maeda, A. Bismarck B.J. Briscoe: Mechanisms of scratching frictions and damage maps for rubber compounds. Wear 259, 651 2005

W. Brostow, B. Bujard, P.E. Cassidy, H.E. Hagg P. Montemartini: Effects of fluoropolymer addition to an epoxy on scratch depth and recovery. Mater. Res. Innovat. 6, 7 2002

A. de la Isla, W. Brostow, B. Bujard, M. Estevez, J.R. Rodriguez, S. Vargas V.M. Castano: Nanohybrid scratch resistant coatings for teeth and bone viscoelasticity manifested in tribology. Mater. Res. Innovat. 7, 110 2003

W. Brostow, G. Darmarla, J. Howe D. Pietkiewicz Determination of wear of surfaces by scratch testing. e-Polymers 025, 200

W. Brostow M. Jaklewicz: Friction and scratch resistance of polymer liquid crystals: Effects of magnetic field orientation. J. Mater. Res. 19, 1038 2004

M.D. Bermúdez, W. Brostow, F.J. Carrion-Vilches, J.J. Cervantes D. Pietkiewicz: Wear of thermoplastics determined by multiple scratching. e-Polymers, 001 (2005)

M.D. Bermúdez, W. Brostow, F.J. Carrion-Vilches, J.J. Cervantes, G. Damarla J.M. Perez: Scratch velocity and wear resistance. e-Polymers, 003 (2005)

W. Brostow, J.A. Hinze R. Simoes: Tribological behavior of polymers simulated by molecular dynamics. J. Mater. Res. 19, 851 2004

W. Brostow, H.E. Hagg Lobland M. Narkis: Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 21, 2422 2006

S. Yoshida, J.C. Sangleboef T. Rouxel: Quantitative evaluation of indentation-induced densification in glass. J. Mater. Res. 20, 3404 2005

B. Bhushan, R.E. Davis H.R. Kolar: Metallurgical re-examination of wear modes: II. Adhesive and abrasive. Thin Solid Films 123, 113 1985

W. Brostow R. Simoes: Tribological and mechanical behavior of polymers simulated by molecular dynamics. J. Mater. Ed. 27, 19 2005

Acknowledgments

Partial financial support has been provided by the Robert A. Welch Foundation, Houston, TX, (Grant No. B-1203) and also by a Royal Thai Fellowship, Bangkok (to W. Chonkaew). The constructive comments of a referee are appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brostow, W., Chonkaew, W., Rapoport, L. et al. Grooves in scratch testing. Journal of Materials Research 22, 2483–2487 (2007). https://doi.org/10.1557/jmr.2007.0307

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0307