Abstract

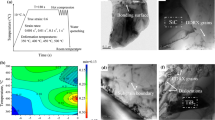

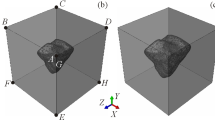

The mechanical behavior [i.e., stiffness, strength, and toughness (KIC)] of SiC Al–Si–Mg metal–ceramic composites (50:50 by volume) was studied at temperatures ranging from 25 to 500 °C. The SiC phase was derived from wood precursors, which resulted in an interconnected anisotropic ceramic that constrained the pressure melt-infiltrated aluminum alloy. The composites were made using SiC derived from two woods (sapele and beech) and were studied in three orthogonal orientations. The mechanical properties and corresponding deformation micromechanisms were different in the longitudinal (LO) and transverse directions, but the influence of the precursor wood was small. The LO behavior was controlled by the rigid SiC preform and the load transfer from the metal to the ceramic. Moduli in this orientation were lower than the Halpin–Tsai predictions due to the nonlinear and nonparallel nature of the Al-filled pores. The LO KIC agreed with the Ashby model for the KIC contribution of ductile inclusions in a brittle ceramic.

Similar content being viewed by others

References

A.R. de Arellano-López, J. Martinez-Fernandez, P. Gonzalez, C. Dominguez, V. Fernandez-Quero M. Singh: Biomorphic SiC: A new engineering ceramic material. Int. J. Appl. Ceram. Technol. 1, 56 2004

J. Martinez-Fernandez, F.M. Valera-Feria M. Singh: High temperature compressive mechanical behavior of biomorphic silicon carbide ceramics. Scripta Mater. 43, 813 2000

M. Presas, J.Y. Pastor, J. Llorca, A.R. de Arellano-López, J. Martinez-Fernandez R.E. Sepulveda: Mechanical behavior of biomorphic Si/SiC porous composites. Scripta Mater. 53, 1175 2005

M. Singh J.A. Salem: Mechanical properties and microstructure of biomorphic silicon carbide ceramics fabricated from wood precursors. J. Eur. Ceram. Soc. 22, 2709 2002

M. Singh B.M. Yee: Reactive processing of environmentally conscious, biomorphic ceramics from natural wood precursors. J. Eur. Ceram. Soc. 24, 209 2004

F.M. Varela-Feria, J. Martinez-Fernandez, A.R. de Arellano-Lopez, M. Singh: Low density biomorphic silicon carbide: Microstructure and mechanical properties. J. Eur. Ceram. Soc. 22, 2719 2002

A. Herzog, U.F. Vogt, S. Siegmann O. Beffort: Aluminium metal matrix composites based on biomorphic silicon carbide. Adv. Eng. Mater. 8, 980 2006

T.E. Wilkes, M.L. Young, R.E. Sepulveda, D.C. Dunand K.T. Faber: Composites by aluminum infiltration of porous silicon carbide derived from wood precursors. Scripta Mater. 55, 1083 2006

C. Zollfrank, N. Travitzky, H. Sieber, T. Selchert P. Greil: Biomorphous SiSiC/Al-Si ceramic composites manufactured by squeeze casting: Microstructure and mechanical properties. Adv. Eng. Mater. 7, 743 2005

J.M. Dinwoodie: Wood: Nature’s Cellular, Polymeric, Fibre-Composite Institute of Metals London, Brookfield, VT 1989

L.J. Gibson M.F. Ashby: Cellular Solids: Structure and Properties, 2nd ed. Cambridge University Press Cambridge, UK, New York 1997

V.S. Kaul, K.T. Faber, R. Sepulveda, A.R. de Arellano-López J. Martinez-Fernandez: Precursor selection and its role in the mechanical properties of porous SiC derived from wood. Mater. Sci. Eng., A 428, 225 2006

K.E. Pappacena, K.T. Faber, H. Wang W.D. Porter: Thermal conductivity of porous silicon carbide derived from wood precursors. J. Am. Ceram. Soc. 90, 2855 2007

A. Mortensen, V.J. Michaud M.C. Flemings: Pressure-infiltration processing of reinforced aluminum. JOM J. Miner. Met. Mater. Soc. 45, 36 1993

A.C. Ferro B. Derby: Wetting behavior in the Al-Si/SiC system: Interface reactions and solubility effects. Acta Metall. Mater. 43, 3061 1995

M.I. Pech-Canul, R.N. Katz M.M. Makhlouf: Optimum parameters for wetting silicon carbide by aluminum alloys. Metall. Mater. Trans. A 31, 565 2000

B.D. Flinn, C.S. Lo, F.W. Zok A.G. Evans: Fracture-resistance characteristics of a metal-toughened ceramic. J. Am. Ceram. Soc. 76, 369 1993

L.S. Sigl, P.A. Mataga, B.J. Dalgleish, R.M. McMeeking A.G. Evans: On the toughness of brittle materials reinforced with a ductile phase. Acta Metall. 36, 945 1988

M.F. Ashby, F.J. Blunt M. Bannister: Flow characteristics of highly constrained metal wires. Acta Metall. 37, 1847 1989

H.E. Dève S. Schmauder: Role of interface properties on the toughness of brittle matrix composites reinforced with ductile fibers. J. Mater. Res. 7, 3132 1992

K.K. Chawla: Composite Materials: Science and Engineering 2nd ed. Springer New York 1998

J.T. Blucher: Discussion of a liquid-metal pressure infiltration process to produce metal matrix composites. J. Mater. Process. Technol. 30, 381 1992

ASTM C373-88 Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products ASTM International West Conshohocken, PA 1988

ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials ASTM International West Conshohocken, PA 2001

ASTM C1161-02c Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature ASTM International West Conshohocken, PA 2003

G.V. Guinea, J.Y. Pastor, J. Planas M. Elices: Stress intensity factor, compliance and CMOD for a general three-point-bend beam. Int. J. Fract. 89, 103 ASTM International West Conshohocken, PA 1998

ASTM C1421-01b Standard Test Method for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature ASTM International West Conshohocken, PA 2002

Y.X. Wang, S.H. Tan D.L. Jiang: The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC. Carbon 42, 1833 2004

Q.G. Wang C.J. Davidson: Solidification and precipitation behaviour of Al-Si-Mg casting alloys. J. Mater. Sci. 36, 739 2001

A. Mortensen I. Jin: Solidification processing of metal matrix composites. Int. Mater. Rev. 37, 101 1992

V.S. Kaul K.T. Faber: Nanoindentation analysis of the elastic properties of porous SiC derived from wood. Scripta Mater. 58, 886 2008

G.T. Hahn A.R. Rosenfield: Metallurgical factors affecting fracture toughness of aluminum-alloys. Metall. Trans. A 6, 653 1975

M.I. Pech-Canul M.M. Makhlouf: Processing of Al-SiCp metal matrix composites by pressureless infiltration of SiCp preforms. J. Mater. Synth. Proc. 8, 35 2000

A.R. Studart, U.T. Gonzenbach, E. Tervoort L.J. Gauckler: Processing routes to macroporous ceramics: A review. J. Am. Ceram. Soc. 89, 1771 2006

T.W. Clyne P.J. Withers: An Introduction to Metal Matrix Composites Cambridge University Press New York 1993

K.T. Faber A.G. Evans: Intergranular crack-deflection toughening in silicon-carbide. J. Am. Ceram. Soc. 66, C94 1983

Acknowledgments

The financial support from the National Science Foundation through grants DMR-0244258/0710630, from the Ministerio de Educación y Ciencia through grant MAT2007-29278-E, and from the Comunidad de Madrid through the Materiales Estructurales Avanzados ESTRUMAT program (S-0505/MAT-0077) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wilkes, T., Pastor, J., Llorca, J. et al. Mechanical properties of wood-derived silicon carbide aluminum-alloy composites as a function of temperature. Journal of Materials Research 23, 1732–1743 (2008). https://doi.org/10.1557/JMR.2008.0197

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0197