The Paton Welding Journal, 2014, #12, 25-31 pages

E.O. Paton Electric Welding Institute, NASU. 11 Bozhenko Str., 03680, Kiev, Ukraine. E-mail: office@paton.kiev.ua

Abstract

Capabilities and prospects for application of linear friction welding for joining various metallic materials, namely steels, titanium alloys, high-temperature nickel alloys and composite materials are considered. Parameters of the mode of linear friction welding for different material combinations and their mechanical properties are given. Structure of joints in linear friction welding is similar to that for other friction welding variants. Width of characteristic joint sections (zones of dynamic recrystallization, thermomechanical and thermal impact) depends on mode parameters - welding time, axial force, vibration amplitude and frequency. Modern tendencies in modelling of heat evolution and deformation in linear friction welding are analyzed. Cost reduction and improvement of reliability of equipment for realization of this process remain an urgent problem. At present the field of industrial application of this process is limited to aerospace companies, where components of gas turbine engines from titanium alloys are joined, and in the future application of high-temperature and nickel alloy and composite materials is possible. 35 Ref., 5 Figures.

Keywords: linear friction welding, process stages, joint structure, modelling, titanium alloys, high-temperature nickel alloys, composite materials

Received: 09.10.14

Published: 29.12.14

References

1. Lebedev, V.K., Chernenko, I.A., Vill, V.I. et al. (1987) Friction welding: Refer. Book. Leningrad: Mashinostroenie.

2. Vill, V.I. (1962) Friction welding of metals. New York: American Welding Soc.

3. Vavilov, A.F., Voinov, V.P. (1964) Friction welding. Moscow: Mashinostroenie.

4. Maurya, R., Kauzlarich, J. Bonding apparatus - friction welding by reciprocal motion. Pat. US 3420428-A. Publ. 1969.

5. Kulis, E.I., Lokishin, R.F. (1982) Friction welding of plastics. Svarochn. Proizvodstvo, 1, 8-9.

6. Nicholas, E.D., Hone, P. (1989) Developments in friction and MIAB welding. Welding Institute Bull., R382/11/89.

7. Nicholas, E.D. (1991) Linear friction welding. Duesseldorf: DVS Verl., DVS Berichte, 139, 18-24.

8. Nicholas, E.D. (1992) Friction surfacing and linear friction welding. In: Proc. of Int. SAMPE and Metals Proc. Conf. (Covina, CA, USA, 1992), 450-463.

9. Bhamji, I., Preuss, M., Threadgill, P.L. et al. (2010) Solid state joining of metals by linear friction welding: A literature review. Mater. Sci. & Technol., 27(1), 2-12. https://doi.org/10.1179/026708310X520510

10. Usani, U. Ofem, Colegrove, P.A., Addison, A. et al. (2010) Energy and force analysis of linear friction welds in a medium carbon steel. Sci. and Technol. of Welding & Joining, 15(6), 479-485. https://doi.org/10.1179/136217110X12731414739790

11. Vairis, A., Frost, M. (1998) High frequency linear friction welding of a titanium alloy. Wear, 217, 117-131. https://doi.org/10.1016/S0043-1648(98)00145-8

12. Wanjara, P., Jahazi, M. (2005) Linear friction welding of Ti-6Al-4V: Processing, microstructure and mechanical property interrelationships, metal. Mater. Transact. A, 36, 2149-2164. https://doi.org/10.1007/s11661-005-0335-5

13. Netwig, A. (1993) Entwicklung und Trends beim Reibschweissen. Der Praktiker, 9, 546-555.

14. Koo, H.H., Baeslack, W.A. (1992) Friction welding of rapidly solidified Al-Fe-V-Si alloy. Welding J., 5, 20-24.

15. Addison, A., Threadgill, P. (2010) Initial studies of linear friction welding of C-Mn steel. Welding and Cutting, 4, 364-370.

16. Bhamji, I., Preuss, M., Threadgill, P.L. et al. (2010) Linear friction welding of AISI 316L stainless steel. Mater. Sci. and Eng., 528, 680-690. https://doi.org/10.1016/j.msea.2010.09.043

17. Kallee, S.W., Nicholas, E.D., Russell, M.J. (2003) Friction welding of aeroengine components. In: Proc. of 10th World Conf. on Titanium (Hamburg, Germany, 2003), 2859-2867.

18. Evolution of microstructure, microtexture and mechanical properties in linear friction welded titanium alloys. digitool.library.mcgill.ca/thesisfile 103485. pdf

19. Corzo, M., Torres, Y., Anglada, M. et al. (2007) Fracture behaviour of linear friction welds in titanium alloys. Annales de la Mecanica de Fractura, 1, 75-80.

20. Diakonov, G.S., Izmajlova, N.F., Bychkov, V.M. et al. (2012) Examination of weld zone microstructure in linear friction welding of VT6 and VT8 titanium alloys. Vestnik UGATU, 16(7), 48-52.

21. Medvedev, A.Yu., Bychkov, V.M., Selivanov, A.S. et al. (2012) Application of linear friction welding for joining of VT6 and VT8-1 alloys. Ibid., 16(7), 63-67.

22. Chamanfar, A., Jahazi, M., Gholipour, J. et al. (2011) Mechanical property and microstructure of linear friction welded WASPALLOY. Metallurg. and Mater. Transact. A, 42(March), 729-744. https://doi.org/10.1007/s11661-010-0457-2

23. Ola, O.T., Ojo, O.A., Wanjara, P. et al. (2012) Analysis of microstructural changes induced by linear friction welding in a nickel-base superalloy. Ibid., 42 (Dec.), 3761-3777.

24. Linear friction welding of IN-718: Process optimization and microstructure evolution http://www.scientific.net/AMR.15-17.357

25. Ola, O.T., Ojo, O.A., Wanjara, P. et al. (2012) A study of linear friction weld microstructure in single crystal CMSX-486 superalloy. Metallurg. and Mater. Transact. A, 43(March), 921-933. https://doi.org/10.1007/s11661-011-0928-0

26. Bychkov, V.M., Selivanov, A.S., Medvedev, A.Yu. et al. (2012) Study of weldability of heat-resistant nickel alloy EP742 by method of linear friction welding. Vestik UGATU, 16(7), 112-116.

27. Rotundo, F., Ceschini, L., Morri, A. et al. (2010) Mechanical and microstructural characterization of 2124Al/25 vol.% SiCp joints obtained by linear friction welding (LFWptA). Composites, 41, 1028-1037. https://doi.org/10.1016/j.compositesa.2010.03.009

28. Karavaeva, M.V., Kiselyova, S.K., Bychkov, V.M. et al. (2012) Influence of upset value on formation of welded joint in linear friction welding. Pisma o Materialakh, 2, 40-44.

29. Medvedev, A.Yu., Pavlinich, S.P., Atroshchenko, V.V. et al. (2010) Modeling of temperature field in linear friction welding. Vestik UGATU, 14(2), 75-79.

30. Wen-Ya Li, Tiejun Ma, Jinglong Li. (2010) Numerical simulation of linear friction welding of titanium alloy: Effects of processing parameters. Materials and Design, 31, 1497-1507. https://doi.org/10.1016/j.matdes.2009.08.023

31. Grujicic, M., Arakere, G., Pandurangan, B. et al. (2012) Process modeling of Ti-6Al-4V linear friction welding (LFW). J. Mater. Eng. and Performance, 21(10), 2011-2023. https://doi.org/10.1007/s11665-011-0097-8

32. The importance of materials data and modeling parameters in an FE simulation of linear friction welding. http://www.hindawi.com/journals

33. Kiselyeva, S.K., Yamileva, A.M., Karavaeva, M.V. et al. (2012) Computer modeling of linear friction welding based on the joint microstructure. J. Eng. Sci. and Technol. Rev., 5, 44-47.

34. Turner, R., Gebelin, J.-C., Ward, R.M. et al. (2011) Linear friction welding of Ti-6Al-4V modeling and validation. Acta Materialia, 59, 3792-3803. https://doi.org/10.1016/j.actamat.2011.02.028

35. Linear friction welding of high strength chains. http://www.raiser.de/download/innovationspreis /bewerber2013/Linear_Friction_Welding_of_High_ Strength_Chains_Mucic-Fuchs-Enzinger.pdf

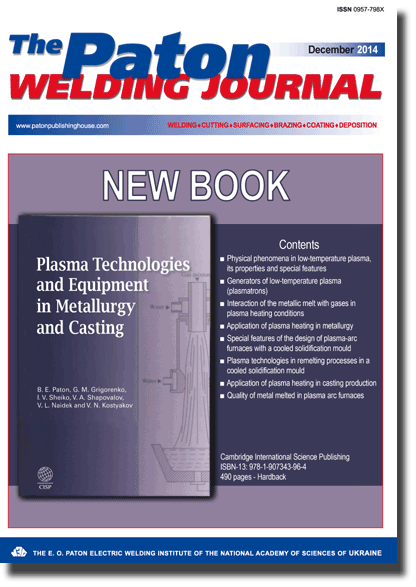

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.

| 2014 №12 (05) |

DOI of Article 10.15407/tpwj2014.12.06 |

2014 №12 (07) |

The Paton Welding Journal, 2014, #12, 25-31 pages

Linear friction welding of metallic materials (Review)

I.V. Zyakhor, M.S. Zavertanny And S.V. Chernobaj

E.O. Paton Electric Welding Institute, NASU. 11 Bozhenko Str., 03680, Kiev, Ukraine. E-mail: office@paton.kiev.ua

Abstract

Capabilities and prospects for application of linear friction welding for joining various metallic materials, namely steels, titanium alloys, high-temperature nickel alloys and composite materials are considered. Parameters of the mode of linear friction welding for different material combinations and their mechanical properties are given. Structure of joints in linear friction welding is similar to that for other friction welding variants. Width of characteristic joint sections (zones of dynamic recrystallization, thermomechanical and thermal impact) depends on mode parameters - welding time, axial force, vibration amplitude and frequency. Modern tendencies in modelling of heat evolution and deformation in linear friction welding are analyzed. Cost reduction and improvement of reliability of equipment for realization of this process remain an urgent problem. At present the field of industrial application of this process is limited to aerospace companies, where components of gas turbine engines from titanium alloys are joined, and in the future application of high-temperature and nickel alloy and composite materials is possible. 35 Ref., 5 Figures.

Keywords: linear friction welding, process stages, joint structure, modelling, titanium alloys, high-temperature nickel alloys, composite materials

Received: 09.10.14

Published: 29.12.14

References

1. Lebedev, V.K., Chernenko, I.A., Vill, V.I. et al. (1987) Friction welding: Refer. Book. Leningrad: Mashinostroenie.

2. Vill, V.I. (1962) Friction welding of metals. New York: American Welding Soc.

3. Vavilov, A.F., Voinov, V.P. (1964) Friction welding. Moscow: Mashinostroenie.

4. Maurya, R., Kauzlarich, J. Bonding apparatus - friction welding by reciprocal motion. Pat. US 3420428-A. Publ. 1969.

5. Kulis, E.I., Lokishin, R.F. (1982) Friction welding of plastics. Svarochn. Proizvodstvo, 1, 8-9.

6. Nicholas, E.D., Hone, P. (1989) Developments in friction and MIAB welding. Welding Institute Bull., R382/11/89.

7. Nicholas, E.D. (1991) Linear friction welding. Duesseldorf: DVS Verl., DVS Berichte, 139, 18-24.

8. Nicholas, E.D. (1992) Friction surfacing and linear friction welding. In: Proc. of Int. SAMPE and Metals Proc. Conf. (Covina, CA, USA, 1992), 450-463.

9. Bhamji, I., Preuss, M., Threadgill, P.L. et al. (2010) Solid state joining of metals by linear friction welding: A literature review. Mater. Sci. & Technol., 27(1), 2-12. https://doi.org/10.1179/026708310X520510

10. Usani, U. Ofem, Colegrove, P.A., Addison, A. et al. (2010) Energy and force analysis of linear friction welds in a medium carbon steel. Sci. and Technol. of Welding & Joining, 15(6), 479-485. https://doi.org/10.1179/136217110X12731414739790

11. Vairis, A., Frost, M. (1998) High frequency linear friction welding of a titanium alloy. Wear, 217, 117-131. https://doi.org/10.1016/S0043-1648(98)00145-8

12. Wanjara, P., Jahazi, M. (2005) Linear friction welding of Ti-6Al-4V: Processing, microstructure and mechanical property interrelationships, metal. Mater. Transact. A, 36, 2149-2164. https://doi.org/10.1007/s11661-005-0335-5

13. Netwig, A. (1993) Entwicklung und Trends beim Reibschweissen. Der Praktiker, 9, 546-555.

14. Koo, H.H., Baeslack, W.A. (1992) Friction welding of rapidly solidified Al-Fe-V-Si alloy. Welding J., 5, 20-24.

15. Addison, A., Threadgill, P. (2010) Initial studies of linear friction welding of C-Mn steel. Welding and Cutting, 4, 364-370.

16. Bhamji, I., Preuss, M., Threadgill, P.L. et al. (2010) Linear friction welding of AISI 316L stainless steel. Mater. Sci. and Eng., 528, 680-690. https://doi.org/10.1016/j.msea.2010.09.043

17. Kallee, S.W., Nicholas, E.D., Russell, M.J. (2003) Friction welding of aeroengine components. In: Proc. of 10th World Conf. on Titanium (Hamburg, Germany, 2003), 2859-2867.

18. Evolution of microstructure, microtexture and mechanical properties in linear friction welded titanium alloys. digitool.library.mcgill.ca/thesisfile 103485. pdf

19. Corzo, M., Torres, Y., Anglada, M. et al. (2007) Fracture behaviour of linear friction welds in titanium alloys. Annales de la Mecanica de Fractura, 1, 75-80.

20. Diakonov, G.S., Izmajlova, N.F., Bychkov, V.M. et al. (2012) Examination of weld zone microstructure in linear friction welding of VT6 and VT8 titanium alloys. Vestnik UGATU, 16(7), 48-52.

21. Medvedev, A.Yu., Bychkov, V.M., Selivanov, A.S. et al. (2012) Application of linear friction welding for joining of VT6 and VT8-1 alloys. Ibid., 16(7), 63-67.

22. Chamanfar, A., Jahazi, M., Gholipour, J. et al. (2011) Mechanical property and microstructure of linear friction welded WASPALLOY. Metallurg. and Mater. Transact. A, 42(March), 729-744. https://doi.org/10.1007/s11661-010-0457-2

23. Ola, O.T., Ojo, O.A., Wanjara, P. et al. (2012) Analysis of microstructural changes induced by linear friction welding in a nickel-base superalloy. Ibid., 42 (Dec.), 3761-3777.

24. Linear friction welding of IN-718: Process optimization and microstructure evolution http://www.scientific.net/AMR.15-17.357

25. Ola, O.T., Ojo, O.A., Wanjara, P. et al. (2012) A study of linear friction weld microstructure in single crystal CMSX-486 superalloy. Metallurg. and Mater. Transact. A, 43(March), 921-933. https://doi.org/10.1007/s11661-011-0928-0

26. Bychkov, V.M., Selivanov, A.S., Medvedev, A.Yu. et al. (2012) Study of weldability of heat-resistant nickel alloy EP742 by method of linear friction welding. Vestik UGATU, 16(7), 112-116.

27. Rotundo, F., Ceschini, L., Morri, A. et al. (2010) Mechanical and microstructural characterization of 2124Al/25 vol.% SiCp joints obtained by linear friction welding (LFWptA). Composites, 41, 1028-1037. https://doi.org/10.1016/j.compositesa.2010.03.009

28. Karavaeva, M.V., Kiselyova, S.K., Bychkov, V.M. et al. (2012) Influence of upset value on formation of welded joint in linear friction welding. Pisma o Materialakh, 2, 40-44.

29. Medvedev, A.Yu., Pavlinich, S.P., Atroshchenko, V.V. et al. (2010) Modeling of temperature field in linear friction welding. Vestik UGATU, 14(2), 75-79.

30. Wen-Ya Li, Tiejun Ma, Jinglong Li. (2010) Numerical simulation of linear friction welding of titanium alloy: Effects of processing parameters. Materials and Design, 31, 1497-1507. https://doi.org/10.1016/j.matdes.2009.08.023

31. Grujicic, M., Arakere, G., Pandurangan, B. et al. (2012) Process modeling of Ti-6Al-4V linear friction welding (LFW). J. Mater. Eng. and Performance, 21(10), 2011-2023. https://doi.org/10.1007/s11665-011-0097-8

32. The importance of materials data and modeling parameters in an FE simulation of linear friction welding. http://www.hindawi.com/journals

33. Kiselyeva, S.K., Yamileva, A.M., Karavaeva, M.V. et al. (2012) Computer modeling of linear friction welding based on the joint microstructure. J. Eng. Sci. and Technol. Rev., 5, 44-47.

34. Turner, R., Gebelin, J.-C., Ward, R.M. et al. (2011) Linear friction welding of Ti-6Al-4V modeling and validation. Acta Materialia, 59, 3792-3803. https://doi.org/10.1016/j.actamat.2011.02.028

35. Linear friction welding of high strength chains. http://www.raiser.de/download/innovationspreis /bewerber2013/Linear_Friction_Welding_of_High_ Strength_Chains_Mucic-Fuchs-Enzinger.pdf

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 16 $ |

| AS/EUR | 180 € | 30 € | 25 € | 15 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 16 $ |

| TPWJ/EUR | 360 € | 30 € | 25 € | 15 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 16 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 15 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 16 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.