Abstract

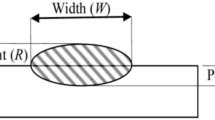

Predictable and reproducible weld bead morphologies and dimensions are a major concern in welding. In bead-on-plate welding, the heat flow is controlled by the heat source parameters (power, speed, and radius) and the physical properties and dimensions of the workpiece, especially its thickness. Complex models that account for weld pool circulation have been developed to quantify welds. However, to some extent, fluctuations in weld dimensions can be explained with conduction models of moving Gaussian heat sources. In early investigations with point and line heat sources, relationships between process parameters and plate thickness were derived to differentiate between two- and three-dimensional heat flow. To date, the heat source radius (R) has not been taken into account. The dimensionless ratio (D*) of the plate thickness (D) to the heat source radius (R) is actually a variable to consider. With the introduction of additional dimensionless parameters (*)—speed (v*), power(q*)— relationships among governing variables, heat flow dimension, and weld bead dimensional fluctuations can be derived. Weld bead fluctuations are found to depend on dimensionless variables (v*, q*, D* ) and occur when the heat flow dimension is intermediate between two- and three-dimensional. Occasionally, experimental data exhibit trends that differ from predictions. This article presents a dimensionless version of a heat flow model and discusses the discrepancies between experimental and theoretical results.

Similar content being viewed by others

References

K. Ishizaki,Proc. Int. Conf. on Arc Physics and Weld Pool Behavior, TWI, Abington Hall, Cambridge, England, 1980, p 267–277

V.A. Bukarov, Y.S. Ishchenko, and V.G. Loshakova,Svar. Proizvod., Vol 11, 1978, p 4–7

P. Burgardt and R.D. Campbell,Key Engineering Materials, Ferrous Alloy Weldments, Vol 69 and 70, D.L. Olson and T.H. North, Ed., Trans. Tech Publications, 1992, p 379–416

B.J. Bradstreet,Weld. J., Vol 47 (No. 7), 1968, p 314s-322s

K. Ishizak, Dynamic Surface Tension and Surface Enthalpy Theory on Heat Transfer and Penetration in Arc Welding, IIW (International Institute of Welding) Doc. No. 212-736-89, 1989

S.K. Marya and D.L. Olson,Mém. étud. Sci. Rev. Métall, 1989, p 25–34

S.K. Marya,Scr. Mater, Vol 34 (No. 11), 1996, p 1771–1745

P. Burgardt and C.R. Heiple,Weld. J., Vol 71 (No. 9), 1992, p 341s-346s

T. Zacharia, S.A. David, J.M. Vitek, and T. Debroy,Weld. J., Vol 68 (No. 12), 1989, p 499s-509s

S.J. Bless, IIW (International Institute of Welding) Doc. No. 212-235-90, 1990

K.C. Mills and BJ. Keene,Int. Mater. Rev, Vol 35 (No. 4), 1990, p 185–216

C.R. Heiple and J.R. Roper,Weld. J., Vol 61 (No. 4), 1982, p 97s-105s

BJ. Keene, K.C. Mills, and R.F. Brooks,Mater. Sci. Technol., Vol 1, 1985, p 568–574

D. Rosenthal,Weld. J., Vol 20 (No. 5), 1941, p 220s-234s

T.W. Eager and N.S. Tsai,Weld. J., Vol 62 (No. 12), 1983, p 346s-355s

J. Goldak, M. Bibby, J. Moore, R. House, and B. Partel,Metall. Trans. B, Vol 17 (No. 3), 1986, p 587–600

J.W. Elmer, W.H. Giedt and T.W. Eager,Weld. J., Vol 69 (No. 5), 1990, p 167s-176s

N. Christensen, V. Davies, and K. Gjermundsen,B. Weld. J., Vol 12 (No. 2), 1965, p 54–75

S. Kou,Metall. Trans. A, Vol 13 (No. 3), 1982, p 363–371

H.R. Shercliff and M.F. Ashby,Metall. Trans. A, Vol 22 (No. 10), 1991, p 2459–2466

M. Marya and S.K. Marya,Proc. First ASM Int. European Conf., (Madrid) ASM International, 1997, p 18–26

P. Jhaveri, W.G. Moffatt, and C.M. Adams,Weld. J., Vol 41, 1962, p l2s-16s

Chapter 3,Welding Handbook, 8th ed., Vol 1, American Welding Society, 1987, p 66–87

Author information

Authors and Affiliations

Additional information

Formerly with ECN.

Rights and permissions

About this article

Cite this article

Marya, M., Marya, S.K. A theoretical and experimental analysis of variances in weld bead morphologies. J. of Materi Eng and Perform 7, 515–523 (1998). https://doi.org/10.1361/105994998770347675

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994998770347675