Abstract

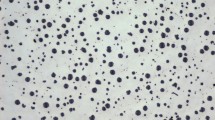

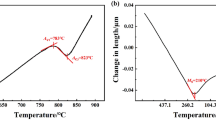

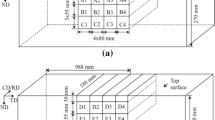

This article describes a series of microstructural and strength studies performed on hypoeutectic cast iron, which was sand cast using a variety of end chills (metallic, nonmetallic, water-cooled, and subzero, respectively). The effects of cooling rate on the eutectic cell count (ECC), grain size, and the ultimate tensile strength (UTS) were evaluated. Attempts were also made to explain these effects and to correlate the UTS with ECC. It was found that subzero chilled and water-cool, chilled cast iron exhibit severe undercooling compared to normal sand cast iron. It was concluded from this investigation that nucleation conditions are completely altered but growth conditions prevail as usual. Therefore, undercooling during solidification is considered to be responsible for variation in ECC, grain size, microstructure, and tensile strength.

Similar content being viewed by others

References

J. Hemanth et al., Wear, Vol 192, 1996, p 134

J. Hemanth et al., J. Mater. Des., Vol 16, 1995, p 175

AFS Cast Metals Handbook, 4th ed., 1957, p 82

R.T. Wimber, Trans. AFS, Vol 88, 1980, p 717

D.O. Morton, Foundry Pract., Vol 200, 1979, p 87

D.M. Stefunescu and C.R. Loper, Giesserei, Vol 5, 1981, p 73

T.J. Baker, Materials in Engineering Application, Vol 1, 1978, p 13

K. Suzuki and N. Kayama, Trans. AFS, Vol 90, 1982, p 423

R.T. De Hoff and F.N. Rhines, Quantitative Microscopy, Wiley & Co., UK, 1980, p 282

H. Fedriksson and M. Hillert, Br. Foundryman, Vol 34, 1971, p 54

D. Glover et al., Trans. AFS, Vol 90, 1982, p 745

R.W. Heine and C.R. Loper, Trans. AFS, Vol 77, 1969, p 185

G.F. Ruff and J.F. Wallace, Trans. AFS, Vol 85, 1977, p 179

J.V. Dawson and W. Oldfield, BCIRA J., Vol 8, 1960, p 221

P. Le Rolland and E. Plenard, Foundrie, Vol 131, 1956, p 477

A.G. Fuller et al., BCIRA J., Vol 11, 1956, p 358

G.N.T. Gilbert, Br. Foundryman, Vol 43, 1968, p 264

H.K. Bishop et al., Trans. AFS, Vol 59, 1951, p 435

J.T. Berry, Trans. AFS, Vol 78, 1970, p 421

D. Glover and C.E. Bates, Trans. AFS, Vol 91, 1983, p 235

J. Hemanth et al., J. Mater. Sci., Vol 33, 1998, p 23

G.F. Ruff and J.F. Wallace, J. Mater. Sci., Vol 81, 1977, p 179

G.X. Sun and C.R. Loper, J. Mater. Sci., Vol 87, 1983, p 841

J.F. Wallace, J. Mater. Sci., Vol 79, 1975, p 363

N. Church et al., J. Mater. Sci., Vol 68, 1966, p 113

B.E. Read Hill, Physical Metallurgy Principles, East West Press, New Delhi, India, 1974, p 665

G.F. Ruff and J.F. Wallace, J. Mater. Sci., Vol 80, 1976, p 705

A.B. Michael and M.B. Bever, Trans. AIME, Vol 188, 1950, p 47

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hemanth, J., Rao, K.V.S. Effect of cooling rate on eutectic cell count, grain size, microstructure, and ultimate tensile strength of hypoeutectic cast iron. J. of Materi Eng and Perform 8, 417–423 (1999). https://doi.org/10.1361/105994999770346701

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994999770346701