Abstract

Drug-excipient compatibility study (DECS) is one of the critical steps during pre-formulation studies to select the appropriate excipient to obtain a stable formulation/dosage form. As such, there is no recommended guideline for DECS. Further, the previously reported studies and protocols followed by various pharmaceutical industries are very lengthy and laborious. Therefore, to improve the existing study strategies and rapid screening of suitable excipients during formulation development, a novel vial-in-vial approach has been proposed. The devised approach was compared with the previously reported conventional approaches using six different drugs with multiple marketed formulations from different manufacturers for each drug. To validate the proposed novel approach, several reported strategies/methodologies have been executed such as exposure of formulations with and without primary packaging, crushed blend with and without water, and/or acetonitrile at accelerated stability condition of 40°C/75% RH for 3 to 6 months and compared with the novel approach. Eventually, all the samples were subjected to HPLC analysis to evaluate the degradation behaviour. The results suggested that the novel approach demonstrated discriminating results with significant degradation as compared to the conventional approaches. Consequently, exercising this methodology for screening the excipients is expected to shorten the drug development cycle by many folds. Moreover, it has also been anticipated that the developed novel approach would prevent the occurrence of late-stage surprises during stability studies.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Soon after winning the race for investigational new drug approval, the next step is to develop a stable formulation for clinical supply with the most suitable excipients[1]. Despite being recognized as inert, excipients can have a substantial impact on drug stability as they can interact with drug substances. The reason for chemical reactions/degradation of the drug includes adsorption of water during storage, generation of microenvironmental pH, and activation of functional groups present in excipients/impurities of excipients in the presence of light, heat, and moisture during storage. For instance, the excipients containing reducing sugars (e.g. lactose, maltose, and glucose) or the presence of reducing sugar as an impurity in excipients such as microcrystalline cellulose can promote Maillard reaction in primary and secondary amine-containing drugs[2,3,4,5,6,7]. Peroxides or phenolic impurities present in povidone and crospovidone can lead to the oxidation or photodegradation of the drug[8, 9]. There are many reports on the observation of aldehydes in lactose, MCC, starch, PEG, etc. that can also cause drug degradation[10, 11]. Therefore, drug-excipient compatibility study (DECS) is being carried out at the pre-formulation stage to select the pertinent excipients for formulation development. The DECS is not only an important but also an obligatory part of regulatory submission. All abbreviated new drug application submission requires a detailed DECS as a part of generic formulation development, where usually the excipient used in generic formulations is different from the innovator formulation. According to ICH Q8, it is also a mandatory requirement to assess the compatibility of Active Pharmaceutical Ingredients (API) with all excipients included in the formulation development[12,13,14].

Industry 4.0 is growing swiftly across the board, and any excess time spent on product development has a significant negative economic influence on the industry’s sustainability. The traditional DECS is a labor-intensive and tedious procedure, where a binary or multi-component physical mixture of drugs and excipients is prepared and charged on stability at accelerated conditions (with or without water) for an extended period of time. Further, the samples are analyzed at a pre-specified time point, usually 1 to 3 months[15, 16]. Hence, there is a constant need for an effective and reliable approach that can screen excipients rapidly.

The studies between the interaction of API and excipients have been the subject of discussion among scientists for decades and a few approaches have been put forward to save time and expenses[8]. A DECS methodology adopted by Serajuddin et al. involves adding 20% water to the drug-excipient blend and charging it at 50°C[17]. However, in this study, additional water has been added to each sample, which shall not always be the case in actual oral solid formulations. Further, excessively added water might force hydrolysis even if the excipients used are non-hygroscopic. In another system proposed by Sims et al., the drug-excipient blend was stressed to 100°C and 80°C in the specially designed vial and block system[18]. The temperature applied for the study was very extreme, which can produce unrealistic degradation products (DPs) of the drug substance. In an attempt to perform high-throughput screening for DECS, Wyttenbach et al. placed 10–20 mg excipient to each well of 96-well plate, followed by the addition of 20 µL of drug solution prepared at the concentration of 5 mg/mL in ethanol[19]. The samples were charged at 40°C or 50°C and 10% or 75% RH. Most of the BCS class II and IV molecules have poor water solubility to achieve 5 mg/mL concentration. Moreover, the solvent other than water may lead to a very different/non-realistic environment for the excipient to behave during stability conditions. None of the above-reported techniques offers realistic and discriminative opportunities for excipients to produce a suitable microenvironment for the drug. Several other methods based on differential thermal calorimetry, thermogravimetry, Raman spectroscopy, FTIR spectroscopy, and the XRPD principle are also reported in the literature[20,21,22,23]. Although the above techniques have the advantage of being rapid with low sample size requirements, they do have the limitation of complex data interpretation. Furthermore, the type of degradation occurred cannot be identified, and most importantly, the role of microenvironmental pH on the degradation of drugs cannot be assessed.

The endeavor of the current study is to propose a unique approach for DECS where a balance between time and realistic conditions can be achieved. Moreover, the target procedural attribute was to allow the drug-excipient(s) mixture to absorb moisture based on their physicochemical characteristics and have a chemical interaction. The proposed approach has been validated with six different drugs and compared with six other traditional/reported approaches.

Experimental

Materials and Reagents

Formulations from different manufacturers of valsartan, irbesartan, glibenclamide, gliclazide, glimepiride, and vildagliptin were purchased from local pharmacy suppliers and considered separate blends of particular drugs. HPLC grade potassium dihydrogen orthophosphate was purchased from Sigma-Aldrich (Darmstadt, Germany), and HPLC grade orthophosphoric acid, acetonitrile (ACN), and potassium hydroxide were procured from Thermo Fisher Scientific Pvt. Ltd. (Mumbai, India). Milli-Q water required during the study was collected from the in-house Millipore water purification system (Milford, USA).

Apparatus and Equipment

The entire study was carried out on an Agilent 1260 Infinity II series equipped with a quaternary pump (DEAEU02368), autosampler (DEAEQ40962), and diode array detector (DEAC614413) with OpenLab software. The chromatographic separation was achieved using an Agilent Eclipse Plus C18 column (250 × 4.6 mm, 5 µm) which was placed in a temperature-controlled column compartment to maintain a constant temperature throughout the study. Other equipment used during the study involved a precision analytical balance (XS205, Mettler Toledo, Schwerzenbach, Switzerland) for accurate weighing. A pH meter (Eutech pH 510, Thermo Fisher Scientific, Mumbai, India) was used to adjust the pH of the buffer. The pH meter was calibrated regularly using NIST traceable standard buffers purchased from Inorganic Ventures (Christiansburg, Virginia). A hot air oven (Heratherm OMS 180, Thermo Fisher Scientific, Mumbai, India) was used for sample generation at high temperatures. The samples were charged in stability chambers (Thermolab Scientific Equipment, Mumbai, India) maintained at 40°C/75% RH. Other equipment used during the study were Vortex (3020, Tarsons, Kolkata, India), Sonicator (GT-1860QTS, Antech, GuangDong GT Ultrasonic, China), Centrifuge (Sorvall Legend X1R, Thermo Fisher Scientific, Mumbai, India), and Micro-pipette (Eppendorf, Hamburg, Germany).

Chromatographic Conditions

For chromatographic analysis, separate HPLC-based methods were developed for each drug. The mobile phase included potassium dihydrogen orthophosphate (5 mM) with varying pH as the aqueous phase (A) and ACN as the organic phase (B). The aqueous phase was filtered through a 0.45 µm vacuum filter and sonicated for 10 min before use. Agilent Eclipse Plus C18 column (250 × 4.6 mm, 5 µm) with a flow rate of 1 mL/min and 5 µL injection volume was employed for the study. The diluent used for extraction of drug from the blend was optimized to be ACN:water (80:20). The gradient of the mobile phase was varied systematically to achieve a reasonable separation. To develop the related substance (RS) method, each drug was subjected to acidic, basic, neutral, and oxidative stress conditions for 24 h by adding 5 mL of 0.1N HCl, 0.1N NaOH, water, and 3% H2O2 to 5 mg equivalent drug in blend, respectively. The samples obtained after stress degradation were used for the development of the RS method to achieve reasonable separation between all the possible DPs.

Determination of Microenvironmental pH

Microenvironmental pH plays one of the major roles in drug degradation; therefore, its estimation is of utmost importance, as it can further be correlated with the extent of drug degradation. For the estimation of microenvironmental pH, the methodology proposed by Serajuddin et al. was selected, which included adding 1 mL of water to 200 mg of crushed blend, followed by uniform mixing using a vortex mixer, and then measuring the pH[17].

Drug-Excipient Compatibility Study

The differences between the physicochemical properties such as static charge and particle size between drug and excipients result into variations in intimate contact between them. Eventually, this may cause variation in the end results. Therefore, to obtain a similar contact at each time point, we selected the formulations that are already available in the market where the drug is uniformly dispersed in excipient matrix. Moreover, to observe the interaction between different excipients and the drug substance, multiple commercial formulations of the same API produced by different manufacturers have been selected. In the present study, valsartan, irbesartan, glibenclamide, glimepiride, gliclazide, and vildagliptin were selected by considering the ease of availability of marketed formulations from multiple manufacturers. For each drug, four to six marketed formulations were procured, which furnished in-total 32 formulations. All 32 formulations were considered separate blend respective to 6 drugs. The investigation was carried out in accordance with the planned protocol, which included the weighing and crushing of the tablets of each drug. Further, 5 mg equivalent drug in drug-excipient blend was weighed and transferred into separate vials. In total, seven stability conditions were chosen for the DECS study. In conditions 1 and 2, as such/intact tablet with and without primary packaging were charged, respectively. The tablets were initially weighed and crushed for the rest of the conditions. In condition 3, ~5 mg equivalent drug in drug-excipient blend was weighed and transferred to an open vial whereas, in condition 4, the drug-excipient blend containing ~5 mg of the drug was put in an open vial with 100 µL of water. Condition 5 involved adding 100 µL of ACN to ~5 mg equivalent drug in drug-excipient blend, followed by condition 6 where 100 µL of premixed water and ACN (50:50) was added to ~5 mg equivalent drug in drug-excipient blend. All the aforementioned conditions were charged at accelerated conditions of 40°C/75% RH. The newly developed vial-in-vial (VV) approach involves a 10-mL vial in which crushed blend (~5mg) was transferred. Further, an insert was kept inside the vial, which was filled with 500 µL of water. The vial was then crimped off and stored at 60°C for the period of 1 and 2 weeks. At 60°C, the water inside the vial evaporates and saturates the environment with humidity. Table I comprises the representative images of all the conditions along with their sampling time points. A comprehensive DECS was conducted for 928 samples to increase the level of confidence in the developed approach.

Principal Component Analysis

All DECS data was examined by Principal Component Analysis (PCA) using SIMCA® software (Version 16) from Sartorius Stedim Data Analytics. The observed PCA scatter plots were projected in a two-dimensional plane to evaluate the observed statistical differences in various DECS conditions.

Results and Discussion

Chromatographic Conditions

For each drug, a separate HPLC analytical method was developed using a common LC column, LC flow, and injection volume by varying mobile phase composition and gradient of elution. Considering the pKa of the drug, mobile phase pH was selected, whereas the gradient elution was optimized by keeping the cLogP of the drug and the required separation of DPs in view. The structure, pKa, cLogP, and optimized chromatographic gradient along with the detection maxima for each drug are tabulated in supplementary file S1.

Determination of Microenvironmental pH

Drug degradation can be caused by an unfavourable pH, and hence, assessing the microenvironmental pH of drug-excipient blend along with their degradation profile provides a direct indication of formulation stability with the chosen excipients. The microenvironmental pH of all blends was determined as per the protocol reported by Serajuddin et al.[17] and it is compiled in table S2 of the supplementary data. There are non-significant differences in microenvironmental pH of different manufacturers’ product of the same drug. Thus, the observed variations in the compatibility study could be due to potential differences in the excipients used or the impurities present in those excipients.

Drug-Excipient Compatibility Study

Study Design

A detailed DECS of all the selected blends was executed in total 7 conditions with different study duration. Herein, the applicability of the proposed novel approach was examined in comparison to different techniques reported in the literature. The detailed literature revealed that water plays an important role in drug degradation as it promotes degradation kinetics. Therefore, Serajuddin et al. recommended the addition of 20% water to the drug and excipient mixture before charging to the stress condition. For the current study, 100 µL water was added in ~ 5 mg equivalent drug in drug-excipient blend. In another study, Wyttenbach et al. considered organic solvent (ethanol) to solubilize the drug substance for enhancing the intimate contact between drug and excipient. Considering the solubility of all 6 drugs, 100 µL ACN was added in ~ 5 mg equivalent drug in drug-excipient blend to mimic the reported condition. Further, to assist the combined effect of aqueous and organic solvents on DECS, 100 µL of a solvent mixture containing water and ACN (50:50) was added in ~ 5 mg equivalent drug in drug-excipient blend. Apart from this condition, samples with and without primary packaging were also charged on stability studies for 1, 3, and 6 months, to mimic the actual stability conditions. Each of the aforementioned samples was charged on stability at accelerated conditions (40°C/75% RH). At each respective time point, the samples were prepared and injected into the HPLC.

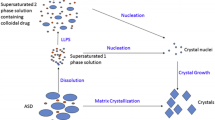

Figure 1 demonstrates the overall drug degradation pathway in the presence of excipients. Briefly, tablet/solid formulations compose of mainly two components, i.e. API and excipients. At the initial stage, the API and excipients are maintained in their physical state having specific surface properties and moisture content based on the manufacturing process. However, at specific RH, moisture gets transmitted through primary packaging at a water vapor transmission rate and gets adsorbed on the surface of the drug and excipients based on their hygroscopicity. The adsorbed moisture generates microenvironment by solubilizing API and excipient components. These micro-pockets are having intimate contact between drug and excipients. Moreover, microenvironmental pH gets generated based on the pKa of solubilized components. They may also have dissolved oxygen content based on environmental conditions. In presence of temperature and light, the drug may get degraded in this microenvironment. However, in practical scenario, the role of light in drug degradation has been reduced as packaging material retards light reaching to formulation. Thus, the major contributors in degradation of drug in the presence of excipients are RH and temperature.

Baertschi et al. demonstrated that the majority of the small molecules follow the same degradation kinetics up to ~ 70°C [24]. To propose accelerated study condition for DECS, a new VV approach has been devised, where the temperature was optimized to be 60°C considering the reported literature [24]. Additionally, the sample was also maintained in a close environment where a small insert filled with water was kept inside the main vial. When the 60°C temperature is achieved, the water evaporates and drug-excipient blend has been allowed to adsorb moisture based on their hygroscopic properties unlike adding direct water to the mixture. Table II comprises the comparative favourability of each study condition on a scale of less favourable to strongly favourable. The duration of study has been scaled to less favourable, reasonably favourable, and strongly favourable based on the study duration of ≥ 12 weeks, 2–12 weeks, and ≤ 2 weeks, respectively. Further, in terms of ease of experiments, the arduousness of work decided the favourability. Briefly, PP and IT were considered less favourable as it requires a prototype of formulation unlike other conditions, where merely the addition of water/solvent to the blend was required. VV was considered reasonably favourable as it involves the insertion of a small insert containing water in another bigger vial where the blend is present. Additionally, in terms of nearness to realistic conditions, accelerated stability condition, i.e. 40°C/75% RH, produces the most reliable results. However, the addition of water/solvent makes the blend unrealistic/less favourable, as the formulation would never experience physical addition of water/solvent. VV was considered reasonably favourable, where the blend can adsorb moisture based on its hygroscopicity and can show degradation at elevated temperature. Furthermore, the addition of water and/or ACN may lead to a change in polymorphic form or convert to hydrate of the API. Thus, OW, OA, and WA were considered less favourable. Interestingly, PP, IT, NO, and VV are strongly favourable to access degradation based on their intrinsic hygroscopic property unlike conditions of external addition of water which overrules the intrinsic property of blend. The overall discrimination power of the technique is accessed based on the resulting outcome in terms of % degradation. Thereby, VV has provided maximum discrimination between samples and proved strongly favourable in the assessment of suitable excipients.

Degradation Behaviour of Drugs in DECS

A comparative study was conducted for all 6 drugs in 7 conditions. In DECS of valsartan, it was observed that the proposed VV approach produced higher degradation in 1 week as compared to other 6 conditions. The overlaid HPLC chromatogram is depicted in figure S1 of the supplementary data. Valsartan showed 0.00 to 12.65% degradation in varied conditions. Among all the six blends of valsartan, blend 2 showed the most degradation in all conditions which proves that VV is mimicking the other conditions just accelerating the degradation without changing the trends. Moreover, the variety of DPs formed was also higher in blend 2. Figure 2 depicts the compiled data of valsartan DECS of all six blends. The figure indicates that the proposed VV approach showed higher degradation in 1 week as compared to all other approaches studied for 3 or 6 months. Hence, it can be considered a potential alternative to conventional DECS.

In the case of gliclazide, when all six blends were charged for DECS under the selected conditions, it led to the similar outcome where VV produced higher degradation in 1 week than the other studied approaches. In gliclazide, 2–10 folds increase in total percent degradation was observed in 1-week VV condition as compared to 3–6-month studies. The overlaid chromatograms of all six blends are shown in figure S2 of the supplementary data. Only one DP was obtained in all six blends, and among all, blend 6 showed maximum degradation; thus, gliclazide can be considered relatively stable. Figure 3 represents the compiled data of all the conditions of gliclazide, which implies that the proposed VV approach produces relatively higher degradation in 1 week, and hence, it can be an alternative to select the correct excipient for formulation development.

As a result of DECS of glimepiride, all six blends showed significantly higher degradation in the proposed VV approach within 1 week only. Figure 4 illustrates the compiled data of all six blends of glimepiride, where blend six showed higher degradation as compared to other blends. The overlaid HPLC chromatogram of all six blends of glimepiride is presented in figure S3 of the supplementary data.

All four blends of irbesartan were subjected to the designed DECS conditions. The results indicated that the VV produced relatively higher degradation in 1–2 weeks as compared to the 3–6 months studies of other conditions. Irbesartan was highly degrading in the conditions where the sample came directly in contact with water. Among all the blends, blend 3 showed comparatively higher degradation. Figure 5 represents the compiled DECS data of all the blends of irbesartan, whereas figure S4 of supplementary data shows the overlaid HPLC chromatogram for irbesartan.

In glibenclamide DECS, all the four blends were charged for the study. The results indicated that the VV approach produced parallel degradation in 2 weeks as compared to 3 to 6 months duration of all other approaches. Figure 6 shows the compiled data of DECS for all four blends of glibenclamide. The overlaid HPLC chromatogram of all the blends of glibenclamide is shown in figure S5 of the supplementary data.

In vildagliptin study, the proposed VV approach produced significantly higher degradation in 1 week as compared to all other approaches. It was observed that vildagliptin was highly susceptible and degraded to a higher extent. Vildagliptin degradation ranged from 0.08 to 99.48% in different conditions where maximum degradation was observed in one to two weeks in VV condition. Figure 7 illustrates the compiled data of all six blends of vildagliptin. The figure clearly indicates that > 90% of drug degraded in the proposed approach in 1 week only. Figure S6 of the supplementary data represents the overlaid HPLC chromatogram of all the vildagliptin blends.

Interestingly, the proposed VV approach produced higher or similar degradation in 1–2 weeks as compared to a 3-month study of other approaches. However, it was observed that there may be chances of the formation of secondary DPs after a specified time as the blend was exposed to higher temperature and humidity for a longer time. Therefore, we can conclude that a 1-week VV condition is sufficient to predict the outcome of DECS, whereas a 2-week VV condition can be considered the worst-case scenario, where all the possible DPs would be generated, and it can help in developing a reliable stability-indicating method.

Distinction of Proposed VV Approach for DECS by PCA

To support chromatographic data, the obtained results were evaluated with the help of PCA. The PCA plots were formed using SIMCA® software where the samples were categorized in accordance to the study conditions. The data was displayed using scatter plots, where total % degradation and individual impurities were considered variables. Figure 8 represents the scatter plot of the obtained data which represents each condition with a distinct colour. The plot was formed using PCA-X model and it clearly demonstrated the discrimination between VV approach as compared to all other approaches. Thus, it justifies that VV approach has formed unequivocally higher degradation as compared to all other conditions. Moreover, grouping shown in 1 and 2 weeks VV data suggest a significant trend in results with respect to number of DPs formed and their relative response.

Conclusion

The acceleration in DECS can expedite the overall drug development process. In the current study, a novel VV approach was proposed to provide thermal and humidity stress to drug-excipient blend. This approach allows drug-excipient mixture to adsorb moisture based on their intrinsic physicochemical property, unlike few reported methodologies. The results demonstrated significant degradation not only quantitatively but also in terms of the variety of degradation products. The applicability of the proposed approach was demonstrated by analyzing six drugs with various blends. Each blend was subjected to seven different conditions for different time frames. In PCA analysis, the proposed approach in comparison with the other conditions including exposure of formulation with and without primary packaging, crushed blend as such, with water and/or acetonitrile at accelerated stability condition of 40°C/75% RH for 3 to 6 months showed a distinct set of attributes. Moreover, the presented approach showed acceleration without changing the rank ordering. Eventually, by comparing all the conditions, we observed that the proposed approach helps in screening the excipients in less time and provides all the possible DPs, which will also aid in establishing a reliable RS method. The overall reduction in DECS can be achieved from 3–6 months to 1–2 weeks. Hence, it will be advantageous for the industry in critical time/emergency situations like COVID-19, where immediate formulation development is need of an hour. However, in a few cases of formulation development, selected storage conditions and packaging materials are the major drivers for excipient selection. In such cases, the driving force between temperature and humidity for degradation behaviour needs to be accessed through separate experiments at 40°C/95% RH and 60°C/75% RH for accelerated DECS.

References

Akkermans WGM, Coppenolle H, Goos P. Optimal design of experiments for excipient compatibility studies. Chemom Intell Lab Syst. 2017;171:125–39. https://doi.org/10.1016/j.chemolab.2017.09.012.

Agarwal A, Asif M, Deshmukh R, Vinchurkar M, Singana SB, Bhondave P. Preclinical toxicological assessment of levothyroxine and liothyronine Maillard impurities. Toxicol Res. 2022;11:743–9. http://www.ncbi.nlm.nih.gov/pubmed/36330073.

Patil DD, Patil CR. Modification of pharmacological activity of nebivolol due to Maillard reaction. Pharm Dev Technol. 2013;18:844–51. https://doi.org/10.3109/10837450.2011.591802.

Chowdhury DK, Sarker H, Schwartz P. Regulatory notes on impact of excipients on drug products and the Maillard reaction. AAPS PharmSciTech. 2018;19:965–9. https://doi.org/10.1208/s12249-017-0878-y.

Szalka M, Lubczak J, Naróg D, Laskowski M, Kaczmarski K. The Maillard reaction of bisoprolol fumarate with various reducing carbohydrates. Eur J Pharm Sci. 2014;59:1–11. https://doi.org/10.1016/j.ejps.2014.04.005.

Wirth DD, Baertschi SW, Johnson RA, Maple SR, Miller MS, Hallenbeck DK, et al. Maillard reaction of lactose and fluoxetine hydrochloride, a secondary amine. J Pharm Sci. 1998;87(1):31–9. https://doi.org/10.1021/js9702067.

Wu Y, Levons J, Narang AS, Raghavan K, Rao VM. Reactive Impurities in excipients : profiling, identification and mitigation of drug – excipient incompatibility. AAPS PharmSciTech. 2011;12(4):1248–63. https://doi.org/10.1208/s12249-011-9677-z.

Bharate SS, Bharate SB, Bajaj AN. Interactions and incompatibilities of pharmaceutical excipients with active pharmaceutical ingredients: a comprehensive review. J Excipients Food Chem. 2010;1(3):3–26.

Hartauer KJ, Arbuthnot GN, Baertschi SW, Johnson RA, Luke WD, Pearson NG, et al. Influence of peroxide impurities in povidone and crospovidone on the stability of raloxifene hydrochloride in tablets: identification and control of an oxidative degradation product. Pharm Dev Technol. 2000;5(3):303–10. https://doi.org/10.1081/PDT-100100545.

Gamble JF, Chiu WS, Gray V, Toale H, Tobyn M, Wu Y. Investigation into the degree of variability in the solid-state properties of common pharmaceutical excipients—anhydrous lactose. AAPS PharmSciTech. 2010;11(4):1552–7. https://doi.org/10.1208/s12249-010-9527-4.

Hemenway JN, Carvalho TC, Mantri RV, Wu Y, Levons JK, Narang AS, et al. Reactive impurities in PEG: a case study. In: Narang AS, Boddu S, editors. Excipient Applications in Formulation Design and Drug Delivery. 2015. p. 67–91. https://doi.org/10.1007/978-3-319-20206-8_4.

Guide for the Quality Module 3 - Part P Finished Product. https://moph.gov.lb/userfiles/files/HealthCareSystem/Pharmaceuticals/QualityAssuranceofPharmaceuticalProducts/GuidelinesEnglishModule3Ppart.pdf. Accessed 19 Jan 2023.

Épshtein NA. Compatibility of medicinal and excipient substances in the development of medicinal formulations. Pharm Chem J. 2018;52(7):648–57. https://doi.org/10.1007/s11094-018-1876-4.

ICH Topic Q8 (R2) Pharmaceutical development. Vol. 8. 2009. https://database.ich.org/sites/default/files/Q8_R2_Guideline.pdf. Accessed 19 Jan 2023.

Thomas VH, Naath M. Design and utilization of the drug-excipient chemical compatibility automated system. Int J Pharm. 2008;359(1–2):150–7. https://doi.org/10.1016/j.ijpharm.2008.03.043.

Monkhouse DC, Maderich A. Whither compatibility testing? Drug Dev Ind Pharm. 1989;15(13):2115–30. https://doi.org/10.3109/03639048909052523.

Serajuddin ATM, Thakur AB, Ghosal RN, Fakes MG, Ranadive SA, Morris RK, et al. Selection of solid dosage form composition through drug − excipient compatibility testing. J Pharm Sci. 1999;88(7):696–704. https://doi.org/10.1021/js980434g.

Sims JL, Carreira JA, Carrier DJ, Crabtree SR, Easton L, Hancock SA, et al. A new approach to accelerated drug-excipient compatibility testing. Pharm Dev Technol. 2003;8(2):119–26. https://doi.org/10.1081/PDT-120018476.

Wyttenbach N, Birringer C, Alsenz J, Kuentz M. Drug-excipient compatibility testing using a high-throughput approach and statistical design. Pharm Dev Technol. 2005;10(4):499–505. https://doi.org/10.1080/10837450500299875.

Marini A, Berbenni V, Pegoretti M, Bruni G, Cofrancesco P, Sinistri C, et al. Drug-excipient compatibility studies by physico-chemical techniques: the case of atenolol. J Therm Anal Calorim. 2003;73(2):547–61. https://doi.org/10.1023/A:1025478129417.

Bruni G, Berbenni V, Milanese C, Girella A, Marini A. Drug-excipient compatibility studies: search of interaction indicators. J Therm Anal Calorim. 2002;68(2):561–73. https://doi.org/10.1007/s10973-009-0382-z.

Bozdaǧ-Pehlivan S, Subaşi B, Vural I, Ünlü N, Çapan Y. Evaluation of drug-excipient interaction in the formulation of celecoxib tablets. Acta Pol Pharm - Drug Res. 2011;68(3):423–33.

Meira RZC, Biscaia IFB, Nogueira C, Murakami FS, Bernardi LS, Oliveira PR. Solid-state characterization and compatibility studies of penciclovir, lysine hydrochloride, and pharmaceutical excipients. Mater. 2019;12(19):3154–68. https://doi.org/10.3390/ma12193154.

Baertschi SW, Jansen PJ. Stress testing: a predictive tool. In: Baertschi SW, editor. Pharmaceutical Stress Testing Predicting Drug Degradation. Florida: Tylor & Francis Group; 2005. p. 13–50.

Acknowledgements

We would like to sincerely thank NIPER-A and the Department of Pharmaceuticals, Ministry of Chemicals and Fertilizers, India, for providing the required support, infrastructure, and Ph.D. fellowship. Author would like to thank contribution of Prof. Saranjit Singh's laboratory at NIPER-SAS Nagar, as the understanding of concept mentioned in Figure 1 was generated in his laboratory during Ravi Shah's PhD research.

Funding

The work was supported by the Department of Pharmaceutical, Ministry of Chemicals and Fertilizers, India.

Author information

Authors and Affiliations

Contributions

Sonali Jain: carrying out experiments, methodology, data formal analysis, data interpretation, data curation, investigation, formal analysis, writing—original draft preparation. Ravi P. Shah: conceptualization, supervision, data interpretation, visualization, writing—review and editing, and project administration. All authors have read and approved the manuscript for publication.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jain, S., Shah, R.P. Drug-Excipient Compatibility Study Through a Novel Vial-in-Vial Experimental Setup: A Benchmark Study. AAPS PharmSciTech 24, 117 (2023). https://doi.org/10.1208/s12249-023-02573-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02573-0