Abstract

In a previous study, generally lower drug release rates from RL:L55 blend coated pellets in neutral/basic release media than in acidic release media were reported. The aim of this study was to obtain information on the drug release mechanism of solid dosage forms coated with blends of Eudragit® RL (RL) and Eudragit® L-55 (L55). Swelling experiments with free films were analyzed spectroscopically and gravimetrically to identify the physicochemical cause for this release behavior. With Raman spectroscopy, the swelling of copolymer films could be monitored. IR spectroscopic investigations on RL:L55 blends immersed in media at pH 6.8 confirmed the formation of interpolyelectrolyte complexes (IPECs) that were not detectable after swelling in hydrochloric acid pH 1.2. Further investigations revealed that these IPECs decreased the extent of ion exchange between the quaternary ammonium groups of RL and the swelling media. This is presumably the reason for the previously reported decreased drug permeability of RL:L55 coatings in neutral/basic media as ion exchange is the determining factor in drug release from RL coated dosage forms. Gravimetric erosion studies confirmed that L55 was not leached out of the film blends during swelling in phosphate buffer pH 6.8. In contrast to all other investigated films, the 4:1 (RL:L55) blend showed an extensive swelling within 24 h at pH 6.8 which explains the reported sigmoidal release behavior of 4:1 blend coated pellets. These results help to understand the release behavior of RL:L55 blend coated solid dosage forms.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Coating of oral solid dosage forms is one option to obtain delayed or sustained drug release.

Delayed drug release can be necessary for local treatment of intestinal disorders (e. g., ulcerative colitis), for drugs that are instable in the acidic gastric environment or for drugs that may lead to an irritation of the stomach mucosa. Delayed drug release may be achieved by coatings of enzymatically degradable as well as coatings of pH-dependent soluble polymers such as enteric coatings (1–3).

Oral dosage forms with sustained drug release are mostly used to prevent the rapid uptake of drugs with a low therapeutic index or to reduce the daily dosing frequency resulting in better patient compliance. Retardation of drug release can be achieved with polymer coatings which are insoluble but swellable in the gastrointestinal tract and thus permeable for drugs to some extent. The drug release mechanism is either diffusion of the drug through the hydrated polymer matrix and/or diffusion through water-filled pores in the coating. Moreover, drug release may be driven by ion exchange in the case of ionic sustained release coatings (4–6).

The cationic ammonium methacrylate copolymers contain quaternary ammonium groups (QAGs) with chloride as counterion. When used as coating, the chloride ions are exchanged during drug release for anions of the surrounding medium or for ions from within the coated dosage form (ionic drug, ionic additive) (7–10). The exchange of the QAG counterions with the surrounding medium develops a water flux with which drug molecules can diffuse out of the dosage form (6). The attraction of the ions in the release medium to the QAGs determines the extent of the water flux and hence the drug release rate. Ions with a weak attraction toward the QAGs develop a high water flux (e. g., acetate, monosuccinate) while ions with a strong attraction develop a low water flux (chloride, nitrate) (6,11,12). In general, di- and multivalent ions are highly attracted to QAGs as they are able to crosslink the QAGs and hence decrease ion exchange, known as the “sealing” effect. The swelling of free cationic methacrylate films is affected by the composition of the swelling medium but cannot be correlated with the release behavior of the respective film coating (6).

Furthermore, the drug permeability depends on the density of QAGs in the film which can be influenced by the type of the ammonium methacrylate copolymer (type A or B, Ph. Eur.) and excipients added to the film such as plasticizers or anti-sticking agents. The release rate from dosage forms coated with ammonium methacrylate copolymer films can also be influenced by the osmotic pressure induced by dissolved substances within the dosage form (9,13). To adjust drug release, it is also possible to introduce further drug diffusion pathways into the film by addition of pore formers, e. g., HPMC (14).

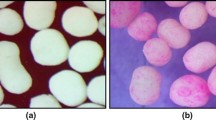

Combinations of ammonium methacrylate copolymers with other polymers have been investigated to evaluate the influence of these polymer blends on drug release (15–17). Of particular interest is the combination with anionic polymers and the potential formation of interpolyelectrolyte complexes (IPECs) (18). Combinations of countercharged polyionic coating polymers may alter drug release by altering the polymer swelling behavior (19,20). Combinations of anionic polymers, particularly polymers for delayed drug release, with ammonium methacrylate copolymers were investigated in various studies (21–25). Polymeric carboxylic acids have been used in combination with quaternary ammonium methacrylates either as bi-layer coatings or polymer blend coatings to achieve colon targeting. Another application for the combination of polymeric carboxylic acids and cationic methacrylates was focused on enhanced drug release in neutral/basic media (25). This was achieved by an enteric coating polymer that served as a pH-dependent pore former in a quaternary ammonium methacrylate coating. In all studies, the release patterns were dependent on the applied blend ratio and the used coating process. Nevertheless, in only few studies ionic interactions were detected. In a recent study, the authors investigated the release behavior of theophylline from pellets coated with blends of Eudragit® RL (ammonium methacrylate copolymer type A, glass transition temperature approx. 50°C) and Eudragit® L55 (methacrylic acid-ethyl acrylate copolymer, glass transition temperature approx. 110°C) from organic solution (11,26). The structures of these copolymers are shown in Fig. 1a, b.

Blends with Eudragit® RL fractions higher than 80.0% showed lower release rates in phosphate buffers between pH 5.8 and pH 7.6 than in hydrochloric acid pH 1.2. However, the release behavior of theophylline from pellets coated with blends of aqueous dispersions of the same copolymers was not influenced by the pH of the release media. It was assumed that the dependency of the release behavior on the coating process (organic vs. aqueous) was coursed by the different degree of polymer chain interdiffusion. However, the reason for the pH-dependent release behavior of pellets coated with copolymer blends from an organic solution remained unclear.

To obtain information on this drug release behavior, physicochemical transformations of free Eudragit® RL: Eudragit® L55 film blends from organic solution during swelling and their swelling behavior was investigated.

MATERIALS AND METHODS

Materials

The copolymers Eudragit® RL PO (RL) and Eudragit® L100–55 (L55) were obtained from Evonik, Germany. Hydrochloric acid 1.0 mol L−1, sodium hydroxide 1.0 mol L−1, trometamol (TRIS), and sodium acetate were all purchased from Carl Roth, Germany. Acetone and isopropanol were obtained by Biesterfeld Spezialchemie, Germany and sodium hydrogen phosphate by Grüssing, Germany. The following swelling media were used: hydrochloric acid pH 1.2, phosphate buffer pH 6.8 (0.05 mol L−1; USP), acetate buffer pH 6.8 (0.05 mol L−1), and TRIS buffer pH 6.8 (0.05 mol L−1). The pH values were adjusted with hydrochloric acid and/or sodium hydroxide. All reactants were of analytical grade and were used as received.

Preparation of Free Copolymer Films

RL and L55 powders were dissolved separately in an organic solvent (acetone 57%, isopropanol 38%, water 5% (w/w)) and mixed in the weight ratios (RL:L55) of 1:0, 4:1, 8:1, 12:1, 16:1, and 0:1, corresponding to RL fractions of 100.0%, 80.0%, 88.9%, 92.3%, 94.1%, and 0.0% (w/w). Furthermore, copolymer solutions of the same copolymer ratios were prepared with 1% triethylcitrate (TEC) as plasticizer. Solutions of RL and L55 are miscible at any ratio and form copolymer films without phase separation.

A predefined mass of all prepared copolymer solutions was cast into individual Teflon® molds and stored in an oven at 40°C and 0% RH for 24 h. This drying process corresponds to standard curing conditions and ensures a minimum and constant residual solvent content in the copolymer films. To remove the organic solvent completely, higher temperatures and/or lower pressure would be required which may significantly affect the copolymer film structure and potentially the copolymer interactions. Therefore, constant drying conditions were chosen to ensure low variability of residual solvent between the different copolymer films. After drying, the films were cut into squares of 20 mm × 20 mm or circles of 6 mm diameter and subsequently stored in a glass container at 0% RH.

Raman Spectroscopy of Swollen Copolymer Films

Copolymer films (6 mm diameter) of the blend ratios (RL:L55) 1:0, 4:1, 8:1, and 0:1 were placed on a microscopic slide, and each film sample was wetted with 50 μL of hydrochloric acid pH 1.2 and phosphate buffer pH 6.8, respectively. After 0, 15, and 30 min of copolymer swelling, the swelling medium was carefully removed with a lint-free tissue and Raman spectra were recorded using the dispersive Raman microscope SENTERRA (Bruker, Germany) with a LMPlanFL N 20 × objective (Olympus, Germany). The laser was operated at 532 nm with a power of 20 mW; four scans with an integration time of 4 s were co-added at a resolution of 1 cm−1. All obtained spectra were manually baseline-corrected (Opus software v. 7.0; Bruker, Germany). Subsequently, the spectral regions with no relevant signals were excluded from further analysis: >3100, 2800–1780, 1400–900, and <560 cm−1.

ATR FTIR Spectroscopy of Swollen Copolymer Films

Quadratic copolymer film samples (20 mm × 20 mm) of the blend ratios (RL/L55) 1:0, 4:1, 8:1, and 0:1 were investigated with ATR FTIR. Three film samples of each blend ratio were immersed in 100 mL of the swelling media at room temperature for 0, 1, 2, and 3 h in an Erlenmeyer flask that was continuously agitated by a benchtop shaker. In media of pH 6.8, L55 samples were removed from the media after 3 min to avoid full dissolution of the films. After swelling, the films were transfered to Teflon® mats and dried in an oven at 40°C and 0% RH for 24 h. IR spectra of the dried films were recorded with a Tensor 37 (Bruker, Germany) equipped with a cooled MCT detector and a MIRacle ATR accessory (PIKE, USA) with a ZnSe crystal plate. The air for continuous purging of the beam path was dried, and carbon dioxide was removed with a SDAT-670/420 double-column air dryer (DRUMAG, Germany). One hundred twenty-eight scans were recorded of each sample at a resolution of 1 cm−1. The spectra were treated with the ATR correction algorithm of the Opus software v. 7.0 (Bruker, Germany).

Chemometrics

All spectra (Raman and IR) were pretreated with the Savitzky-Golay smoothing (13 points, symmetric kernel) and the standard normal variate correction. For further examinations, principal component analysis (PCA) was performed. Pretreatments and PCA were performed with The Unscrambler X software (v. 10.1, Camo, Norway).

Determination of Polymer Erosion of Copolymer Films

The erosion of all prepared copolymer films was determined gravimetrically in hydrochloric acid pH 1.2 and phosphate buffer pH 6.8. Film samples (20 mm × 20 mm) were accurately weighed (w 0) and afterwards immersed in continuously agitated hydrochloric acid pH 1.2 and phosphate buffer pH 6.8 at room temperature. Samples were collected after 0.5 and 24 h, dried on a Teflon® mat in an oven for 24 h at 40°C and afterwards accurately weighted (w E ). The polymer erosion (PE) was calculated as follows:

Determination of the Swelling Index for Copolymer Films

The swelling characteristics of all prepared plasticized copolymer films were determined in hydrochloric acid pH 1.2 and phosphate buffer pH 6.8 at room temperature. Film samples (20 mm × 20 mm) were accurately weighed (w 0), immersed in the agitated media, and removed at several predetermined time points. Residuals of the media adhering to the film samples were carefully wiped off with lint-free tissue, and the samples were immediately weighed (w t ). With the determined weights, a swelling index (SI) was calculated as follows (27):

RESULTS AND DISCUSSION

Raman Spectroscopic Investigation of Swollen Films

Raman spectra of copolymer films were recorded during swelling in hydrochloric acid pH 1.2 and phosphate buffer pH 6.8 to obtain real-time information on the physicochemical transformations within the films during the swelling process. Copolymer films of blend ratios (RL:L55) of 1:0, 4:1, 8:1, and 0:1 were investigated. All obtained Raman spectra were of good quality with a reasonable signal to noise ratio. The spectra recorded from the samples swollen in hydrochloric acid pH 1.2 and phosphate buffer pH 6.8 were analyzed in separate PCAs. The corresponding score plots are displayed in Fig. 2.

Both score plots show a good separation of the different blend ratios along PC-1. PC-2 separates swollen and unswollen films in both media where values of samples swollen in hydrochloric acid pH 1.2 are decreased with longer swelling time and can therefore be differentiated. A similar trend was found for samples swollen in phosphate buffer pH 6.8. Nevertheless, a distinct difference between the 15 and 30 min samples in phosphate buffer was only detected for the L55 samples; Fig. 2b. The nonsignificant changes in the spectra of swollen copolymer films between 15 and 30 min indicate a negligible progress of swelling in phosphate buffer pH 6.8.

The loadings for PC-2 of both PCAs are nearly identical (data not shown) and cannot be attributed to any known chemical or physical change within the copolymer films. For example, the uncharged and the ionized state of L55 cannot be differentiated in the respective Raman spectra. Furthermore, the C-N stretching vibration band of the QAGs in RL at 600 cm−1 does not contribute to the loading of PC-2; thus, changes in the ionic state of QAGs are not described by PC-2 (28).

Although chemical or physical transformations of the polymers during swelling could not be identified, Raman spectroscopy was able to distinguish between swollen and unswollen films. Furthermore, the different PC-2 scores of the samples swollen in hydrochloric acid and those swollen in phosphate buffer pH 6.8 might be a result of different swelling behaviors. Hence, it may be possible to real-time monitor the swelling of polymer films with Raman spectroscopy.

IR Spectroscopic Investigation of Swollen Copolymer Films

IR spectroscopic measurements were performed with swollen and subsequently dried copolymer films to observe physicochemical transformations in RL:L55 film blends resulting from swelling in different media. The investigated film blend ratios were 4:1 and 8:1; plain copolymer films were investigated as references in the same way.

The spectra of copolymer films swollen in hydrochloric acid pH 1.2 were nearly identical to the spectra of the unswollen copolymer films, whereas those of the films swollen in phosphate buffer pH 6.8 were significantly different. The effect of swelling in phosphate buffer pH 6.8 on the spectrum of copolymer film blends is displayed in Fig. 3; as a representative example, the 8:1 copolymer film blend was chosen.

The IR spectra of copolymer films in Fig. 3 show additional at 1567 cm−1 induced by swelling. The inset in Fig. 3 reveals the increasing intensity of the band with progressing swelling time. This band was also found in the spectrum of the 4:1 copolymer blend swollen in phosphate buffer pH 6.8 and can be attributed to the carboxylate groups that originate from deprotonated L55. Interestingly, plain L55 films swollen in phosphate buffer pH 6.8 formed a carboxylate band at 1540 cm−1. This shift of 27 cm−1 was assumed to be the result of ionic interactions between anionic carboxylate groups of L55 and cationic QAGs of RL. To verify this assumption, a PCA was performed with the IR spectra of unswollen copolymer films, samples swollen for 3 h in hydrochloric acid pH 1.2 and samples swollen for 3 h in phosphate buffer pH 6.8. Only spectral regions with bands of ionic groups were considered in the analysis. The stretching vibration band from the carboxylate group of L55 is located between 1600 and 1510 cm−1; the QAG groups of RL show a double band between 1000 and 920 cm−1. The results of the PCA are displayed in Fig. 4.

The PCA score plot in Fig. 4a shows clustering of spectra in different groups. PC-1 explains 88% of the data variability and separates the data points for unswollen copolymer films according to their blend ratio. The spectra of copolymer films swollen in hydrochloric acid pH 1.2 showed slight attenuations in the region between 1000 and 920 cm−1. This effect overlaid the spectral differences between the copolymers resulting in a less distinct separation along PC-1. Copolymer films swollen in phosphate buffer pH 6.8 are not separated according to their blend ratio along PC-1 due to fundamental changes in their spectra compared to the spectra of unswollen copolymer films.

PC-2 explains 8% of the data variability in the IR spectra and separates unswollen copolymer film blends from copolymer films swollen in the respective media. The loading plot of PC-2 in Fig. 4b shows negative values at the carboxylate region with a minimum at 1567 cm−1. Keeping in mind that the abovementioned carboxylate band of plain L55 was located at 1540 cm−1, this band can be considered as a shifted carboxylate band. Additionally, positive values are observed in the region of the QAG double band from approx. 960 to 940 cm−1 with a maximum at 952 cm−1. The highly negative PC-2 scores of film blends swollen in phosphate buffer pH 6.8 indicate the appearance of a new carboxylate band and the attenuation of one of the QAG bands. This confirms an interaction between the ionic groups in the copolymer films after swelling in phosphate buffer. An attenuation of QAG bands and shifts of carboxylate bands resulting from ionic interactions has been described before (18,29,30).

All copolymer films swollen in hydrochloric acid showed slightly lower PC-2 scores resulting from the abovementioned spectral changes in the region between 1000 and 920 cm−1. The negative PC-2 scores for plain copolymer films swollen in phosphate buffer pH 6.8 are caused by new bands in the region between 1600 and 1510 cm−1 and will be discussed later.

It can be hypothesized that the ionic interactions between the copolymers during swelling in phosphate buffer pH 6.8 decreases the extent of ion exchange of QAGs with the surrounding media and thus influencing drug release from dosage forms coated with these copolymer blends.

To investigate the ion exchange of the film blends and their differences compared to the plain films, additional IR spectra of film blends and plain copolymer films swollen in TRIS buffer pH 6.8 and acetate buffer pH 6.8 were recorded. Regarding ion exchange, the spectral region between 1600 and 1500 cm−1 is the most interesting. This region of the IR spectra of plain copolymer films and RL:L55 film blends swollen in different media is displayed in Fig. 5.

The plain RL copolymer films showed a small band at 1580 cm−1 after swelling in phosphate buffer pH 6.8. This might be the result from phosphate anions interacting with QAGs. After swelling in acetate buffer pH 6.8, a band appears at 1571 cm−1 that might be attributed to the carboxylate group of acetate. However, free sodium acetate shows a carboxylate band at 1573 cm−1. This shift of two wave numbers can be the result of ionic interactions between the carboxylate group of acetate and the QAGs of the RL copolymer. Obviously, the negatively charged phosphate and acetate ions migrated at least to a certain extent into the positively charged RL films and interacted electrostatically with the QAGs. After swelling in TRIS buffer pH 6.8, no band in the region between 1600 and 1510 cm−1 was observed. At pH 6.8, TRIS is cationic and therefore its migration into the positively charged RL film is hindered.

L55 copolymer films showed the expected carboxylate band at 1540 cm−1 in phosphate buffer pH 6.8 and in acetate buffer pH 6.8. The spectra of L55 swollen in TRIS buffer is superimposed by strong bands from the TRIS spectrum, for example, the N-H stretching vibration at 3180 cm−1 (data not shown). Obviously, TRIS was at least adsorbed to the surface of L55 films because of electrostatic interactions with the L55 carboxylate groups.

The 4:1 and 8:1 RL:L55 film blends showed the earlier discussed carboxylate band at 1567 cm−1 during swelling in all three media. Interestingly, the intensities of the bands cannot be attributed to the blend ratios but vary between the media. Most probably, this is the result of different swelling behavior depending on the media. The IR spectra of all investigated film blends swollen in media of pH 6.8 showed a carboxylate band at the same wave number independent of the swelling medium. This indicates that all film blends underwent the same ionic interactions in all media of pH 6.8. Furthermore, the spectra indicate that the film blends did not exchange ions with the media of pH 6.8 to an extent that is detectable by IR spectroscopy. In contrast, ion exchange of plain copolymer films with the surrounding medium was clearly detectable. This leads to the assumption that ionic interactions between RL and L55 in film blends at neutral/basic pH decreased the ion exchange with the surrounding media. As a consequence, the drug release rate from dosage forms coated with these blends is lower in neutral/basic media than in acidic media, similar to the “sealing” effect of bivalent ions described by Wagner and Grützmann (6). These findings are particularly interesting, as they may be transferred to film blends of structurally related copolymers, such as ammonium methacrylate copolymer type B and methacrylic acid copolymers (under the precondition of miscibility). Nevertheless, these ionic interactions alone cannot explain the differences in the release rates from dosage forms coated with RL:L55 blends. The intensity of the carboxylate band, and hence, the amount of interacting functional groups was not dependent on the copolymer ratio but on the swelling media. To obtain further information on the differences between the copolymer blends, erosion and swelling experiments were performed.

Investigation of the Erosion of Plain Copolymer Films and Film Blends

Erosion studies can provide valuable information on the integrity of a polymer film during the swelling process. Films might be subject to mechanical stress or leaching out of ingredients into the surrounding medium resulting in changes in drug permeability.

The results of the erosion studies of plasticized copolymer films are displayed in Fig. 6a, the results for unplasticized films are displayed in Fig. 6b.

In phosphate buffer pH 6.8, all L55 films dissolved in less than 0.5 h. In hydrochloric acid pH 1.2, the swelling of plasticized L55 films swollen was not measurable, as it was not possible to detach them from the Teflon® mat after drying. The PE values of plasticized RL films and plasticized RL:L55 blends differ significantly. The PE values of plasticized RL films and all plasticized film blends swollen in hydrochloric acid pH 1.2 were about 6% after 0.5 h and about 12% after 24 h. The respective PE values in phosphate buffer pH 6.8 were slightly lower than those in hydrochloric acid pH 1.2.

The erosion of unplasticized film blends (Fig. 6b) was about 6% after 30 min and increased nonsignificantly after 24 h. This indicates that the weight loss between 0.5 and 24 h of the plasticized films results from TEC leaching out of the copolymer film. The PE value of unplasticized RL copolymer films was slightly lower than the PE values of the copolymer film blends; the PE value of unplasticized L55 was higher after 24 h. This might be explained by differences in the resistance against mechanical erosion caused by the agitated media which could already be observed during handling of the film samples.

The weight loss after 0.5 h can be explained by leaching of residual organic solvent out of the copolymer films and mechanical erosion of the films. Leaching of the pH-dependent soluble L55 out of the film blends was not observed at any time point. The PE values of film blends swollen in phosphate buffer pH 6.8 were lower than the respective values of samples swollen in hydrochloric acid pH 1.2 in most cases. A dependency of PE on the L55 fraction was not found. All film blends were prepared from organic solution resulting in a high polymer-polymer interpenetration of RL and L55. Thus, RL and L55 copolymer chains are highly entangled, and therefore, leaching out of L55 into the surrounding medium is minimized. Such behavior has been described before for film blends of ethyl cellulose and L55 prepared from organic solution (31). Additionally, the ionic interactions between the copolymers might also contribute to the prevention of leaching out of L55 during exposure to phosphate buffer pH 6.8.

Investigation of the Swelling Behavior of Plain Copolymer Films and Film Blends

Polymer swelling is a prerequisite for drug release from coated solid dosage forms. Even though the extent of swelling cannot be correlated with the release behavior of RL-coated dosage forms, knowledge on the swelling behavior of RL:L55 film blends may provide information on the drug release mechanism. Moreover, previous studies have reported an altered polymer swelling behavior as a result of ionic interactions between oppositely charged coating polymers and consequently an altered drug release behavior (19,32). Moreover, the drug permeability of RL:L55 coating blends is generally lower in phosphate buffer pH 6.8 than in hydrochloric acid pH 1.2 (26). The most unusual RL:L55 copolymer with regard to its release behavior was the 4:1 blend. Theophylline pellets coated with the 4:1 blend showed a remarkably long lag time followed by a fast drug release. To identify a relationship between the swelling behavior and the drug permeability of RL:L55 film blends, swelling experiments were performed. The results are displayed in Fig. 7.

For all investigated film samples, swelling in phosphate buffer pH 6.8 led to higher SI values than swelling in hydrochloric acid pH 1.2, with the exception of L55 film samples that dissolved completely in less than 0.5 h at pH 6.8.

The highest SI value of RL was observed after 0.5 h and decreased afterwards (Fig. 7a). The decrease of the SI after the first 0.5 h can be explained by the extraction of plasticizing agents (TEC, residual organic solvents). After fast diffusion of buffer into the plasticized copolymer films, plasticizing agents are leached out of the copolymer films. A decrease of the plasticization is accompanied by a decrease of the swelling capacity; thus, buffer is squeezed out of the film to a certain extent. This phenomenon has been described before for drug-loaded RL films (33). The swelling of L55 films in hydrochloric acid pH 1.2 was initially and reached an SI value of approximately 45% after 4 h (Fig. 7b).

The 4:1 and 8:1 film blend samples reached slightly higher SI values in both media than plain RL films (Fig. 7c, d). Furthermore, the maximum of swelling was observed at later time points. For swelling in hydrochloric acid pH 1.2, this can be explained by the high L55 fraction, a copolymer which initially swells slower but reaches higher SI values than plain RL films after 4 h. Therefore, the swelling behavior of the 4:1 and 8:1 copolymer blends at pH 1.2 can be considered as a combination of the swelling behavior of RL and L55. A similar swelling behavior was observed for swelling of the 4:1 copolymer blend in phosphate buffer pH 6.8 within the first 4 h. Interestingly, the 4:1 blend swollen in phosphate buffer pH 6.8 reached an exceptionally high SI values of 83.2% ± 3.0% after 24 h (data not shown) while with all other samples, the SI value determined at the 4-h time point remained constant. This swelling behavior may be caused by the high amount of carboxylate groups that increase the swelling capacity of the films.

With the 12:1 and 16:1 blends, SI values were highest at the 0.5-h time point and decreased afterwards, similar to plain RL copolymer films (Fig. 7e, f).

The swelling behavior of the plain RL film was only slightly different compared to that of the 8:1, 12:1, and 16:1 film blends. The differences in the drug permeability of these coatings that have been reported by Wulff and Leopold (26) could not be correlated to the presented differences in their swelling behavior. Only the 4:1 blend in phosphate buffer leads to a different result with extensive swelling within 24 h.

For theophylline pellets coated with the 4:1 copolymer blend, a long lag time followed by fast drug release has been reported (26). This lag time can be explained with the decreased extent of ion exchange that might have decreased the drug release rate in the initial phase as discussed above. The fast drug release in the later phase can be explained by the extensive copolymer swelling that might have induced domains of highly hydrated L55. Thus, the release mechanism changed from an ion exchange-driven to a diffusion controlled process with enhanced drug release. Film coatings are usually much thinner than the investigated film samples in the present study, and therefore, their swelling process might be finished earlier. Hence, the lag time is expected to be shorter than 24 h.

CONCLUSION

Free films prepared from organic solutions of Eudragit® RL (RL), Eudragit® L55 (L55), and blends thereof were investigated with regard to their swelling behavior, physicochemical transformations during swelling, and ion exchange with the surrounding media. The overall goal was to obtain a deeper insight into the drug release mechanism of RL:L55-coated dosage forms.

Raman spectroscopy was found to be a promising tool for real-time monitoring of polymer swelling. Nevertheless, the desired information on physicochemical transformations could not be obtained with the applied method. ATR FTIR spectroscopic measurements confirmed the formation of interpolyelectrolyte complexes between the quaternary ammonium groups (QAGs) of RL and the carboxylate groups of L55 during swelling in media at pH 6.8. These ionic interactions decreased the extent of ion exchange between the QAGs and the swelling media. The decrease in the extent of ion exchange was responsible for the reduced drug permeability of RL/L55 blend coatings in media at pH 6.8 compared to that at pH 1.2 which has been described in a previous study.

The swelling behavior of RL:L55 film blend samples was not considerably different from that of plain RL films, except for the swelling of the RL:L55 4:1 blend ratio. Film samples of the 4:1 copolymer blend were found to swell extensively within 24 h. This swelling behavior explains the high drug permeability of 4:1 coatings after a long lag time.

The present study gives important information on the underlying drug release mechanism of RL:L55-coated dosage forms and contributes to the development of tailor-made coated drug delivery systems.

References

Kopeček J, Kopečková P, Brøndsted H, Rathi R, Ríhová B, Yeh PY, et al. Polymers for colon-specific drug delivery. J Control Release. 1992;19:121–30. doi:10.1016/0168-3659(92)90070-8.

Leopold CS. Coated dosage forms for colon-specific drug delivery. Pharm Sci Technol To. 1999;2:197–204. doi:10.1016/S1461-5347(99)00151-0.

Ibekwe VC, Fadda HM, Parsons GE, Basit AW. A comparative in vitro assessment of the drug release performance of pH-responsive polymers for ileo-colonic delivery. Int J Pharm. 2006;308:52–60. doi:10.1016/j.ijpharm.2005.10.038.

Knop K. Influence of buffer solution composition on drug release from pellets coated with neutral and quaternary acrylic polymers and on swelling of free polymer films. Eur J Pharm Sci. 1996;4:293–300. doi:10.1016/0928-0987(96)00176-5.

Bodmeier R, Guo X, Sarabia RE, Skultety PF. The influence of buffer species and strength on diltiazem HCl release from beads coated with the aqueous cationic polymer dispersions, Eudragit RS, RL 30D. Pharm Res. 1996;13:52–6. doi:10.1023/a:1016021115481.

Wagner KG, Grützmann R. Anion-induced water flux as drug release mechanism through cationic Eudragit RS 30D film coatings. AAPS J. 2005;7:E668–77. doi:10.1208/aapsj070367.

Narisawa S, Nagata M, Danyoshi C, Yoshino H, Murata K, Hirakawa Y, et al. An organic acid-induced sigmoidal release system for oral controlled-release preparations. Pharm Res. 1994;11:111–6. doi:10.1023/a:1018910114436.

Narisawa S, Nagata M, Hirakawa Y, Kobayashi M, Yoshino H. An organic acid-induced sigmoidal release system for oral controlled-release preparations. 2. Permeability enhancement of eudragit RS coating led by the physicochemical interactions with organic acid. J Pharm Sci. 1996;85:184–8. doi:10.1021/js950180o.

Narisawa S, Nagata M, Hirakawa Y, Kobayashi M, Yoshino H. An organic acid-induced sigmoidal release system for oral controlled-release preparations. III. Elucidation of the anomalous drug release behavior through osmotic pumping mechanism. Int J Pharm. 1997;148:85–91. doi:10.1016/S0378-5173(96)04834-X.

Sun YM, Hsu SC, Lai JY. Transport properties of ionic drugs in the ammonio methacrylate copolymer membranes. Pharm Res. 2001;18:304–10. doi:10.1023/A:1011098712693.

Skalsky B., Petereit H.U. Chemistry and application properties of polymethacrylate systems. In: McGinity JW, Felton LA, editors. Aqueous polymeric coatings for pharmaceutical dosage forms. vol. 42. CRC Press; 2013. 237–277.

Wagner KG, McGinity JW. Influence of chloride ion exchange on the permeability and drug release of Eudragit RS 30 D films. J Control Release. 2002;82:385–97. doi:10.1016/S0168-3659(02)00145-1.

Heinicke G, Schwartz JB. Ammonio polymethacrylate-coated diltiazem: drug release from single pellets, media dependence, and swelling behavior. Pharm Dev Technol. 2007;12:285–96. doi:10.1080/10837450701247384.

Lippold BC, Monells PR. Control and stability of drug release from diffusion pellets coated with the aqueous quaternary polymethacrylate dispersion Eudragit RS 30 D. Pharmazie. 2001;56:477–83.

Alhnan MA, Basit AW. Engineering polymer blend microparticles: an investigation into the influence of polymer blend distribution and interaction. Eur J Pharm Sci. 2011;42:30–6. doi:10.1016/j.ejps.2010.10.003.

Roy P, Shahiwala A. Multiparticulate formulation approach to pulsatile drug delivery: current perspectives. J Control Release. 2009;134:74–80. doi:10.1016/j.jconrel.2008.11.011.

Gallardo D, Skalsky B, Kleinebudde P. Controlled release solid dosage forms using combinations of (meth)acrylate copolymers. Pharm Dev Technol. 2008;13:413–23. doi:10.1080/10837450802202098.

Moustafine RI, Bodrov AV, Kemenova VA, Rombaut P, Van Den Mooter G. Drug release modification by interpolymer interaction between countercharged types of Eudragit RL 30D and FS 30D in double-layer films. Int J Pharm. 2012;439:17–21. doi:10.1016/j.ijpharm.2012.09.044.

Khuathan N, Pongjanyakul T. Modification of quaternary polymethacrylate films using sodium alginate: film characterization and drug permeability. Int J Pharm. 2014;460:63–72. doi:10.1016/j.ijpharm.2013.10.050.

Moustafine RI, Margulis EB, Sibgatullina LF, Kemenova VA, Van den Mooter G. Comparative evaluation of interpolyelectrolyte complexes of chitosan with Eudragit ® L100 and Eudragit ® L100-55 as potential carriers for oral controlled drug delivery. Eur J Pharm Biopharm. 2008;70:215–25. doi:10.1016/j.ejpb.2008.04.008.

Kadam VD, Gattani SG. Development of colon targeted multiparticulate pulsatile drug delivery system for treating nocturnal asthma. Drug Deliv. 2010;17:343–51. doi:10.3109/10717541003762821.

Ly J, Wu XY. Bimodal release of theophylline from “seed-matrix” beads made of acrylic polymers. Pharm Dev Technol. 1999;4:257–67. doi:10.1081/PDT-100101360.

Piao ZZ, Lee MK, Lee BJ. Colonic release and reduced intestinal tissue damage of coated tablets containing naproxen inclusion complex. Int J Pharm. 2008;350:205–11. doi:10.1016/j.ijpharm.2007.08.044.

Vasilevska K, Djurić Z, Jovanović M, Simov A. Preparation and dissolution characteristics of controlled release diltiazem pellets. Drug Dev Ind Pharm. 1992;18:1649–61. doi:10.3109/03639049209040892.

Wu C, McGinity JW. Influence of an enteric polymer on drug release rates of theophylline from pellets coated with Eudragit RS 30D. Pharm Dev Technol. 2003;8:103–10. doi:10.1081/PDT-120017529.

Wulff R, Leopold CS. Coatings from blends of Eudragit ® RL and L55: a novel approach in pH-controlled drug release. Int J Pharm. 2014;476:78–87. doi:10.1016/j.ijpharm.2014.09.023.

Blanchon S, Couarraze G, Rieg-Falson F, Cohen G, Puisieux F. Permeability of progesterone and a synthetic progestin through methacrylic films. Int J Pharm. 1991;72:1–10. doi:10.1016/0378-5173(91)90374-W.

Md V, Vandenabeele P, Beer T, Remon JP, Moens L. Reference database of Raman spectra of pharmaceutical excipients. J Raman Spectrosc. 2009;40:297–307. doi:10.1002/jrs.2125.

Painter PC, Brozoski BA, Coleman MM. FTIR studies of calcium and sodium ionomers derived from an ethylene methacrylic-acid co-polymer. J Polymer Sci. 1982;20:1069–80. doi:10.1002/pol.1982.180200614.

Rufino ES, Monteiro EEC. Infrared study on methyl methacrylate-methacrylic acid copolymers and their sodium salts. Polymer. 2003;44:7189–98. doi:10.1016/j.polymer.2003.08.041.

Lecomte F, Siepmann J, Walther M, MacRae RJ, Bodmeier R. Polymer blends used for the coating of multiparticulates: comparison of aqueous and organic coating techniques. Pharm Res. 2004;21:882–90. doi:10.1023/B:PHAM.0000026443.71935.cb.

Moustafine RI, Bukhovets AV, Sitenkov AY, Kemenova VA, Rombaut P, Van Den Mooter G. Eudragit E PO as a complementary material for designing oral drug delivery systems with controlled release properties: comparative evaluation of new interpolyelectrolyte complexes with countercharged Eudragit L100 copolymers. Mol Pharm. 2013;10:2630–41. doi:10.1021/mp4000635.

Glaessl B, Siepmann F, Tucker I, Rades T, Siepmann J. Deeper insight into the drug release mechanisms in Eudragit RL-based delivery systems. Int J Pharm. 2010;389:139–46. doi:10.1016/j.ijpharm.2010.01.031.

Acknowledgments

The authors thank U. Gralla and C. Bretzke from the University of Hamburg for their support regarding the Raman spectroscopy. The authors also thank Evonik, Germany, for the donation of Eudragit® RL and L100–55.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wulff, R., Leopold, C.S. Coatings of Eudragit® RL and L-55 Blends: Investigations on the Drug Release Mechanism. AAPS PharmSciTech 17, 493–503 (2016). https://doi.org/10.1208/s12249-015-0377-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-015-0377-y