Abstract

Owing to the very brittle nature of tellurium powder, nanoscopic grains with an average size of 4.8 ± 0.8 nm were produced by dry vibration milling technique using a mixer/mill apparatus. A novel material was obtained by binding the nanosized tellurium grains with poly(methyl methacrylate) (PMMA) polymer. The morphology, elemental composition, and structural and optical properties of Te/PMMA films were investigated. The prepared material was composed of hexagonal tellurium and α-phase of tellurium oxide. The electrical properties of the films were studied, for different electrode contact configurations, in dark condition and under white light illumination varying the optical power density from 2 to 170 mW/cm2 and turning the light on and off cyclically. Data analysis shows that the photoconductivity of the film with sandwich contact configuration is a linear function of the light power density and increases more than 2 orders of magnitude as compared to the photoresponse of the film with coplanar contact configuration.

Similar content being viewed by others

Background

Elemental tellurium is a p-type semiconductor that can be exploited for many technological applications in metallurgy, photovoltaics, photonics, electronics, and medicine [1]. It has been used in the form of thin films or powder to fabricate gas sensors [2, 3], antiseptic materials [4], photoconductors [5–7], thermoelectric devices [8–11], etc. Usually, chemical and electrochemical methods (“bottom-up” approaches), such as chemical vapor deposition [12] and solvothermal synthesis [13], are utilized to produce tellurium-based materials. In particular, one-dimensional (1D) tellurium nanostructures such as wires, rods, tubes, and belts have been synthesized. For example, Rao et al. [14] reported controlled synthesis of Te nanorods, nanowires, nanobelts, and related structures by the disproportionation of NaHTe in different solvents, Xia et al. [15, 16] prepared uniform Te nanowires and nanotubes through the reduction of H6TeO6 by N2H4H2O or ethylene glycol in refluxing process, and Qian’s group produced a series of 1D Te nanostructures including nanowires, nanobelts, and nanotubes via hydrothermal synthesis [17–20]. Recently, Zhu et al. [21] presented an ultrasonic-assisted solution-phase approach for the fabrication of tellurium bundles of nanowhiskers, Sen et al. [22] synthesized Te nanostructures by physical vapor deposition, and Vasileiadis et al. demonstrated that a controlled fabrication of Te nanotubes can be carried out by irradiating bulk elemental Te with continuous wave lasers emitting in visible range for short exposure time [23].

In this paper, results on a top-down approach [24], based on dry vibration milling technology, to reduce the size of a brittle material such as tellurium and produce nanoscopic phases in a simple, effective, and inexpensive way, are reported. Indeed, nanostructures in the form of fine tellurium powder composed of grains with average size of a few nanometers were produced in air, without any temperature control and chemical reactions.

Furthermore, a novel functional material was obtained as monolithic film by binding the tellurium nanopowders with poly(methyl methacrylate) (PMMA), an amorphous thermoplastic polymer widely used in spectroscopic and optoelectronic applications.

Further advantages of this preparation method are the following: (i) the slight toxicity of tellurium is reduced by embedding it in the form of powder into a polymeric matrix thus overcoming the limits for an industrial use, (ii) the tellurium in a hyperfine form allows to achieve high homogeneous tellurium-polymer composites suitable for optical and flexible electronic applications, and (iii) the structural, optical, and electrical properties of the tellurium nanocomposites can be tuned by reducing the tellurium size at nanoscopic scale (tellurium quantum dots).

In order to obtain good electrical transport properties of this tellurium-based material, structures with a filling factor higher than 30 % by weight for nanoscopic tellurium [25] were prepared. The morphology, elemental composition, structural and optical properties of tellurium/PMMA films were analyzed by scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), transmission electron microscopy (TEM), X-ray diffraction (XRD), Fourier transform infrared (FT-IR), and UV-vis-NIR spectroscopies. The electrical properties were investigated in dark condition and under white light illumination with coplanar and sandwich electrode configurations. The time-dependent photocurrent responses were measured turning the light on and off cyclically at different optical power densities of the light.

Methods

Pure tellurium powder (99.8 % by weight, −200 mesh, Aldrich) was placed inside a steel grinding jar with two steel grinding balls. The tellurium grains were dry milled in air at a frequency of 25 Hz, for 7 h using a Mixer Mill apparatus (Retsch, MM-200). The grinding jar performs oscillations in a horizontal position, and the balls impact with high energy on the material thus pulverizing it. The movement of the grinding jar combined with the movement of the balls results in the intensive frictional action on the Te powder. At a frequency of 25 Hz, thousands of impacts per minute are achieved, resulting in a high degree of tellurium pulverization in a very short time.

The obtained powders were converted into monolithic samples by using a little amount of poly(methyl methacrylate) (M w = 996,000 g mol−1) as binder to fabricate Te/PMMA films of large area (ca. 20 cm2). In more detail, PMMA was dissolved in acetone at room temperature, then the powder was added and accurately dispersed by using a sonication bath, and finally, the liquid systems were spin-coated (60 min at 200 rpm.) on a silicon plate as substrate. The sample composition was 11 % by weight in polymer in order to reach a compromise between the minimum amount of polymer to bind the tellurium grains and the maximum concentration of tellurium to obtain suitable electrical properties for device applications. The thickness of the prepared Te/PMMA film, measured by a Millitron electrical length measuring instrument, was about 80 μm. The large-area film was cut into several specimens for each characterization.

The morphology of the tellurium powders and Te/PMMA films was investigated by SEM measurements performed by a FEI QUANTA 200 FEG apparatus equipped with an EDS microanalyzer (Inca Oxford 250), while nanoscopic grain size was determined by TEM measurements carried out by a FEI Tecnai G2 Spirit twin apparatus. In this case, the milled powder was dispersed into an amorphous polymeric matrix (polystyrene, Aldrich), using chloroform as solvent (solvent-mediated method) and depositing such tellurium/polystyrene system on the TEM copper grids. The structural characterizations of the powder samples and Te/PMMA films were carried out by X-ray diffraction and Fourier transform infrared spectroscopy using a PANalytical-X’Pert Pro diffractometer and Nicolet Nexus spectrophotometer, respectively.

The electrical properties were studied at room temperature in a coplanar configuration by depositing Ag paint contacts 4 mm long spaced by 1 mm and in a sandwich configuration covering the top and the bottom surfaces of the film with 3 and 10 mm2 of Ag contacts, respectively. The electrical measurements of the samples were performed in both contact configurations by a Keithley 6485 picoammeter and a Tektronics PS 280 DC power supply. Time-dependent current of the Te/PMMA films was measured switching on and off the white light illumination of an ELC 250 W lamp of General Electric. Optical power density of the light flux was varied from 2 to 170 mW/cm2 by means of neutral density filters and measured by a Laser Precision Rk-5720 power radiometer.

Results and Discussion

Structural and Morphological Analysis

SEM and TEM measurements on Te powder samples were carried out to verify the ability of dry vibration milling technique to produce nanoscopic Te powder for the fabrication of Te/PMMA films. The “as received” tellurium powder was made of quite monodispersed pseudospherical grains with an average size of ca. 30 μm as visible in the SEM micrograph given in Fig. 1a, whereas the milled powder was characterized by a polymodal particle size distribution as displayed in the SEM micrograph in Fig. 1b. Most part of the powder was made of nanoscopic tellurium grains, as can be seen from the TEM image in Fig. 1c. The grain size distribution is shown in the histograms in Fig. 1d, and the average grain diameter was estimated to be 4.8 ± 0.8 nm.

The composition of the milled powder was determined by EDS investigation (see Fig. 2). Data analysis indicates the presence of oxygen, due to the dry-milling process performed in air that can lead to a partial oxidation of the tellurium grain surface, and traces of iron, which is already present in the starting coarse tellurium powder.

Some information on the structural properties of the milled powder was obtained by infrared spectroscopy. Indeed, the FT-IR spectrum of the milled tellurium sample shown in Fig. 3 includes the typical absorption bands of tellurium oxide centered at wavenumbers of 773 and 667 cm−1. According to the literature [26], these two resonances correspond to the symmetrical equatorial and asymmetrical axial stretching frequencies of the Te–O bonds, respectively. Furthermore, a quite broad and intensive absorption band due to the OH stretching vibrational mode, located at a wavenumber of 3436 cm−1, can be detected revealing that the oxide phase was partially hydrated.

Te/PMMA film of large area was obtained by binding the nanoscopic Te grains of the milled powder with PMMA.

The morphology of the film was investigated by SEM. The micrograph, shown in Fig. 4, reveals that the material was quite porous, due to the very high inorganic phase content. In particular, both macro- and micro-porosities can be clearly observed as black areas in the image.

The structural properties of the Te/PMMA material were studied by XRD measurements. In Fig. 5a, the XRD diffractogram shows a prominent peak at 27.32° belonging to the diffraction pattern of the hexagonal tellurium (JCPDS card 36-1452) and two other less intensive diffraction peaks at 25.99° and 29.79° due to the α-phase of tellurium oxide (α-TeO2, JCPDS card 78-1713). Both Te and α-TeO2 phases were already present in the “as received” Te powder, as shown in the XRD spectrum of Fig. 5b; however, in the case of the Te/PMMA film, the peaks are broadened because the sample was composed of nanoscopic Te grains, achieved at the end of the milling process. Furthermore, according to the integrated area of the diffraction peaks, the composition of the film was 53 % Te and 47 % α-TeO2, while for the “as received” powder it was 80.8 % Te and 19.2 % α-TeO2. The higher value of the α-TeO2 phase percentage in the film can be ascribed to an oxidation process of the Te grains occurring during the milling stage.

Optical and Photoconductivity Properties

The optical properties of the Te/PMMA film were investigated by means of transmittance (T) and reflectance (R) spectroscopy in the UV-vis-NIR range. The R/T spectra of the film are shown in Fig. 6. The transmittance increases in the 200–350 nm range, and it is quite constant in the Vis and NIR ranges. The reflectance rapidly decreases in the UV region, slightly decreases in the Vis region, and is quite constant in the NIR region. Thus, from quantitative analysis, the sample absorptance varies in the 0.8–0.9 range in all the UV-vis-NIR regions.

The electrical characterization of the Te/PMMA samples was performed both in coplanar and sandwich configurations. In the dark condition, the I–V characteristic in the coplanar configuration is nonlinear (see Fig. 7a) and the behavior of the absolute value of the current as a function of the applied voltage V is exponential as shown in the semilogarithmic plot of the inset in Fig. 7a. In the sandwich configuration, the I–V characteristic, displayed in Fig. 7b, is quite linear indicating that the contacts are ohmic.

The very different dark conductivity values obtained for the two configurations can be attributed to the film morphology as shown by the SEM image in Fig. 4.

In order to investigate the photoconductivity properties, the samples were illuminated by white light of different power density values. The current under illumination, I light, was measured in coplanar configuration, by applying a bias voltage of 200 V to reach a good signal-to-noise ratio avoiding high power dissipation. The illumination exposure time was held fixed at 440 s and immediately after the light was switched off to obtain light-dark cycles and evaluate the photocurrent, I ph, as I ph = I light − I dark, where I dark was the dark current measured before turning on the light. The evolution of I ph as a function of time for light-dark cycles performed by light power densities of 100, 120, and 170 mW/cm2 is shown in Fig. 8. The photocurrent signal slowly increases under illumination, and the rise time varies in the 100–300 s range. Upon turning off the light, the signal decreases slowly and the decay time varies in the same range. The inset in Fig. 8 shows the maximum value of the photocurrent for each cycle, I phmax, as a function of power density F in the 10–170 mW/cm2 range.

In order to compare the photoconductivity measurements with the literature data concerning the coplanar configuration, the I max/I dark ratio versus the light power density F is plotted in Fig. 9, where I max = I phmax + I dark is the maximum value of the current before turning off the light. The I max/I dark ratio depends quasilinearly on F, and it is worth noting that I max/I dark = 2.8 at F = 100 mW/cm2; thus, the Te/PMMA sample shows a good photosensitivity as in the case of films composed of tellurium nanorods immersed in polydimethylsiloxane [27].

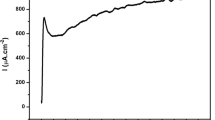

The photoresponse of the Te/PMMA sample in the sandwich configuration for different light-dark cycles is shown in Fig. 10. The measurements were carried out by applying a bias voltage of 12 μV to the sample varying the light power density from 2 to 170 mW/cm2. The duration of the illumination exposure was fixed at 60 s for each cycle. In this case, the rise time of the signal was about 4 s. When the light is removed, the current quickly decreases with a decay time of about 2 s. The inset in Fig. 10 shows that I phmax depends linearly on F.

According to refs. [6, 23, 28], the origin of photoconduction in this material may be attributed to the coexistence of Te and TeO2 phases due to the partial oxidation of Te grains as demonstrated by XRD analysis.

In order to compare the photoresponse of the samples for the two contact configurations, the photocurrent I phmax is plotted as a function of F in Fig. 11 in bi-logarithmic scale. Clearly, in the case of the sandwich configuration, the photocurrent obtained applying only tens of microvolts of bias voltage is more than 2 orders of magnitude greater than the one measured in the coplanar configuration by applying 200 V.

Conclusions

It has been demonstrated that dry vibration milling is a suitable technology for producing tellurium nanoscopic powders. A novel material based on nanosized tellurium bound by means of a thermoplastic polymer such as PMMA was prepared.

The morphological characterizations of Te powders and Te/PMMA films were performed by SEM and TEM, and the films showed a quite porous nature due to the low amount of polymer present in the film. From XRD data analysis, it was obtained that the Te/PMMA material was composed of hexagonal Te and α-phase of tellurium oxide. The optical absorptance of the Te/PMMA sample was found varying in the 0.8–0.9 range in the UV-vis-NIR region. The time-dependent photoconductivity properties of Te/PMMA films were explored under white light illumination, turning the light on and off cyclically in coplanar and sandwich contact configurations. The photoresponse was studied as a function of the optical power density in the 2–170 mW/cm2 range. In the coplanar configuration, the rise and decay times of the photocurrent signal are on the order of hundreds of seconds, while in the sandwich configuration, the signal varies faster and the rise and decay times are just a few seconds. Finally, for the sandwich configuration, a linear correlation between the photocurrent and optical power density, and higher values of the photoresponse were found.

References

Ba LA, Doring V, Jamier V, Jacob C. Tellurium: an element with great biological potency and potential. Org Biomol Chem. 2010;8:4203–16.

Manouchehrian M, Larijani MM, Elahi SM. Thickness and UV irradiation effects on the gas sensing properties of Te thin films. Mat Res Bul. 2015;62:177–83.

Tsiulyanu D, Mocreac O. Hydrogen sensing behavior of tellurium thin films studied by A.C. measurements. Zastita Materijala. 2013;54:107–11.

Lin ZH, Lee CH, Chang HY, Chang HT. Antibacterial activities of tellurium nanomaterials. Chem Asian J. 2013;7(5):930–4.

Anzin VB, Kosichkin YV, Nadezhdinskii AI. An investigation of photoconductivity in tellurium at low temperatures. Sov Phys JETP. 1976;44(5):1032–5.

Oishi K, Okamoto K, Sunada J. Photoconduction of photo-oxidized tellurium thin films. Thin Solid Films. 1987;148:29–40.

Wang Y, Tang Z, Podsiadlo P, Elkasabi Y, Lahann J, Kotov NA. Mirror-like photoconductive layer-by-layer thin films of Te nanowires: the fusion of semiconductor, metal, and insulator properties. Adv Mater. 2006;18:518–22.

Das VD, Jayaprakash N, Soundararajan N. Thermoelectric power of tellurium thin films and its thickness and temperature dependence. J Mater Sci. 1981;16:3331–4.

Sharma AK. Thickness dependence of the thermoelectric power of tellurium films. Phys Stat Sol (a). 1981;77K:81–5.

Bodiul P, Bondarchuk N, Huber T, Konopko L, Nikolaeva A, Botnari O. Thermoelectric properties of films and monocrystalline whiskers of tellurium. ICT'06, 25th International Conference on Thermoelectrics. New York (USA): IEEE; 2006; 607.

Jiang CH, Wei W, Yang ZM, Tian C, Zhang JS. Electrodeposition of tellurium film on polyaniline-coated macroporous phenolic foam and its thermopower. J Porous Mater. 2012;19:819–23.

Kamepalli S, Ovshinsky S. Chemical vapor deposition of chalcogenide materials. U.S. Patent Application 2005;11/046:114.

Deng Y, Zhou XS, Wei GD, Liu J, Nan CW, Zhao SJ. Solvothermal preparation and characterization of nanocrystalline Bi2Te3 powder with different morphology. J Phys and Chem Sol. 2002;63(11):2119–21.

Gautam UK, Rao CNR. Controlled synthesis of crystalline tellurium nanorods, nanowires, nanobelts and related structures by a self-seeding solution process. J Mater Chem. 2004;14:2530.

Mayers B, Xia Y. One-dimensional nanostructures of trigonal tellurium with various morphologies can be synthesized using a solution-phase approach. J Mater Chem. 2002;12:1875.

Mayers B, Xia Y. Formation of tellurium nanotubes through concentration depletion at the surfaces of seeds. Adv Mater. 2002;14:279.

Liu ZP, Hu ZK, Liang JB, Li S, Yang Y, Peng S, et al. Size-controlled synthesis and growth mechanism of monodisperse tellurium nanorods by a surfactant-assisted method. Langmuir. 2004;20:214.

Xi GC, Peng YY, YuWC QYT. Synthesis, characterization, and growth mechanism of tellurium nanotubes. Cryst Growth Des. 2005;5:325.

Xu LQ, Ding YW, Xi GC, Zhang WQ, Peng YY, Yu WC, et al. Large-scale synthesis of crystalline tellurium nanowires with controlled-diameters via a hydrothermal-reduction process. Chem Lett. 2004;33:592.

Mo MS, Zeng JH, Liu XM, Yu WC, Zhang SY, Qian YT. Controlled hydrothermal synthesis of thin single-crystal tellurium nanobelts and nanotubes. Adv Mater. 2002;14:1658.

Zhou B, Zhang JR, Zhao L, Zhu JM, Zhu JJ. A novel ultrasonic-assisted solution-phase approach for the fabrication of tellurium bundles of nanowhiskers. Ultrason Sonochem. 2006;13:352.

Sen S, BhattA UM, Kumar V, Muthe KP, Bhattacharya S, Gupta SK, et al. Synthesis of tellurium nanostructures by physical vapor deposition and their growth mechanism. Cryst Growth Des. 2008;8:238–42.

Vasileiadis T, Dracopoulos V, Kollia M, Yannopoulos SN. Laser-assisted growth of t-Te nanotubes and their controlled photo-induced unzipping to ultrathin core-Te/sheath-TeO2 nanowires. Sci Rep. 2013;3(1209):1–7.

Deng HM, Ding J, Shi Y, Liu XY, Wang J. Ultrafine zinc oxide powders prepared by precipitation/mechanical milling. J Mater Sci. 2001;36:3273–6.

Chung L, Deborah D. Composite materials for thermoelectric applications. London: Comp. Mat. Springer; 2003. p. 101–24.

El-Mallawany RA. Theoretical and experimental IR spectra of binary rare earth telluride glasses-1. Infrared Phys. 1989;29(2–4):781–5.

Li HH, Zhang P, Liang CL, Yang J, Zhou M, Lu XH, et al. Facile electrochemical synthesis of tellurium nanorods and their photoconductive properties. Cryst Res Technol. 2012;47:1069–74.

Vasileiadis T, Yannopoulos SN. Photo-induced oxidation and amorphization of trigonal tellurium: a means to engineer hybrid nanostructures and explore glass structure under spatial confinement. J Appl Phys. 2014;116(103510):1–8.

Acknowledgements

We gratefully acknowledge Dr. Carla Minarini of ENEA-Portici Research Centre for the Optical Measurements and Maria Cristina del Barone of LAMEST laboratory IPCB-CNR for SEM and TEM analysis.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

GC conceived of the experimental design and co-wrote the paper. SDN co-wrote the paper and performed the experimental measurements. UC and GA developed and performed the photoelectrical characterizations and co-wrote the paper. MP participated in the design of the experiment and developed the sample preparation. All authors read and approved the final manuscript.

Authors’ information

GC is a senior researcher at the Institute for Polymers, Composites and Biomaterials, Italian National Research Council. His present research interests are in the field of advanced functional materials based on polymer-embedded inorganic nanostructures. In particular, his activity concerns the development of new chemical routes for the controlled synthesis of metal and semiconductor clusters in polymeric matrices, the fabrication of devices based on properties of nanoscopic objects (luminescence of quantum dots, tunable surface plasmon absorption of nanosized noble metal alloys, etc.), and the investigation of mechanisms involved in atomic and molecular cluster formation in polymeric media (nucleation, growth, aggregation, etc.) by optical and luminescence spectroscopy. He has authored 150 research articles published in international journals, ten patents, and many conference papers. He is the editor of two Wiley books devoted to metal-polymer nanocomposites and is a member of the editorial board of different scientific journals.

SDN received his BS degree in physics from the University of Naples “Federico II”, Italy, in 1982. From 1983 to 1987, he was a system analyst at Elettronica (Rome) and Alenia (Naples). Since 1988, he has been a staff researcher at the Institute of Cybernetics “E. Caianiello” of the National Research Council. Currently, he is a senior researcher at the SPIN Institute (Institute for Superconductors, Oxides and Other Innovative Materials and Devices), National Research Council (CNR). He has been a scientific coordinator of the research project ‘Imaging Techniques for Studying and Analyzing Microstructured Materials’ of the Department of Physics Sciences and Matter Technologies (DSFTM) of the National Research Council. He has been a coordinator of the research unit based at the Institute of Cybernetics in the framework of the Italian National Research FIRB program: Photonic Microdevices in Lithium Niobate. He has contributed to about 300 technical papers in peer-reviewed international journals, book chapters, and conference proceedings. He has served in program committees of several international conferences and has been a referee for various journals in the field of optics and theoretical physics. His research interests include the development of quantum methodologies to the description of coherent phenomena in many body systems, quantum tomography, theoretical modeling for studying dynamical effects in mesoscopic systems and nanostructured polymeric materials, electronic coherent transport in nonconventional superconductors and graphene, and interaction of optical and electron beams in nonlinear media and plasma.

UC is a researcher at the Physics Department of University of Naples “Federico II”. He is a scientific coordinator of the “AmorphousSemiconductors” Laboratory, and the main research activity is based on the deposition by PECVD of micro/nano crystalline silicon, silicon-carbon alloys films and their optical, structural, and electrical characterizations for applications in photodetectors and solar cells. The results of his scientific activity are reported in papers published in international journals, conference proceedings, and scientific books.

GA is a researcher at the Naples University “Federico II”, and her scientific activity is carried out in the “Amorphous semiconductor” laboratory of the Physics Department. In the last years, she studied the optical, electrical, structural, and radiative properties of silicon-based thin films deposited by PECVD for optoelectronic applications. She collaborates with national/international research groups and participated in relevant projects. Her articles were published in international journals, scientific books, and conference proceedings.

MP, PhD in “Materials and Structures Engineering,” degree in Chemical Engineering, is currently a researcher at the Institute for Polymers, Composites and Biomaterials, National Research Council (IPCB-CNR) of Naples. His current scientific interests are related to the thermo-chemical synthesis of metal-polymer nanocomposites and their morphological and structural characterizations, realized by electron microscopy (SEM, TEM) and X-ray powder diffraction (XRD) and optical spectroscopy techniques (UV-visible absorption and emission spectroscopy) to analyze the relation among chemical-physical properties and the nature, size, and shape of these nanomaterials. Furthermore, he studies the mechanical synthesis of brittle metalloids at nanoscopic scale and conductive and photoconductive properties of this systems embedded in polymers matrices, and the mechanical deposition of graphene on polymers substrates and its functionalization with chemical groups. He has several dozens of scientific papers on international journals and several participations at international conferences.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly credited.

About this article

Cite this article

Carotenuto, G., Palomba, M., De Nicola, S. et al. Structural and Photoconductivity Properties of Tellurium/PMMA Films. Nanoscale Res Lett 10, 313 (2015). https://doi.org/10.1186/s11671-015-1007-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-1007-z